Product Specifications

| Prod Model: |

TSPJ160100L |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Model No: |

Tsj160100L |

| Laser Power: |

80W/100W/130W |

| Max.Marking Area: |

1800*1000mm |

| Cooling Way: |

Water Cooling |

| Laser Type: |

Glass CO2 Laser Tube |

| Movement System: |

Single Side Servo System |

| Position Accuracy: |

0.5mm |

| Guarantee: |

One Year |

Product Description

>>>Machine Feature

1. Two working places can alternate vertically and enable the cutting while feeding

2.100% production increase, 10% material consumption decrease and no abrasion on the baseboard

3. Continuous circle cutting and the maxi circle cutting speed: 30m/min

4. Laser power and speed can be matched automatically to ensure the best effects

5. USB2.0 high-speed port

6. Insulation system and high speed difference input and output electro circuit design can avoid the aberrance in distant signal transportation and realize -

7. The 12 working status output and 16 status input, which can easily connect with the working processing.

8.128 files can be save for the off-line computer work, which is proper for large quantity and repeat processing

>>>Technical index| Laser Source Type | Glass CO2 LaserTube | Movement System | Stepping morto system |

| Output Laser Power | 80W | Cooling System | Compulsory Water Circling System |

| Working Area | 1800mmx1000mm | Electrical Voltage | AC220V 5% 50/60Hz |

| Working Table | Honeycomb | Supported File Format | AI / BMP / PLT/ DXF / DST. etc |

| Working Speed | Adjustable | Standard Accessories | 1 Set Of 550W Exhaust Fans |

| Position accuracy | 0.1mm | Optional | 100W/130W/150W laser tubes |

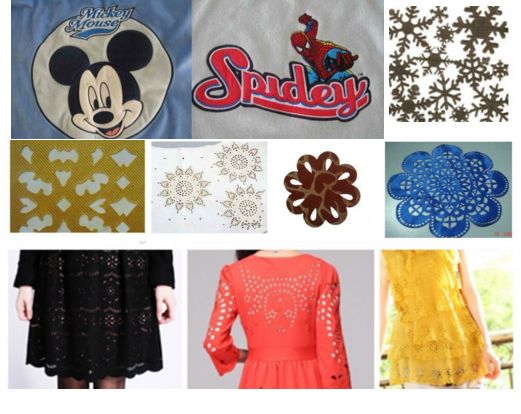

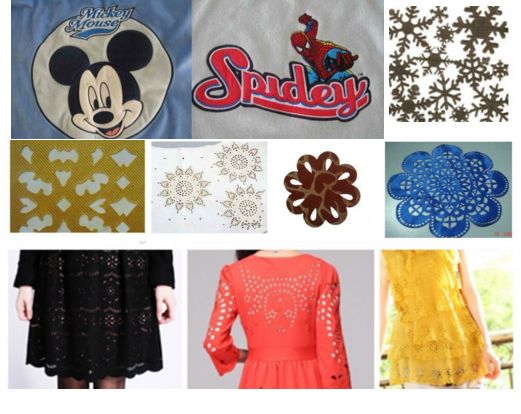

>>>Applicable Industries

Suitable for industries such as billboards, artistic gifts, crystal ornaments, paper cut engraving, bamboo embossment, printing, garments and leather industries, embroidery, interior decoration, frame fabrication and etc.

>>>Applicable Materials

Non-metal materials such as double color boards, acrylic, glass, wood planks, bamboo, rubber, plastic, garments, paper, leather, marble, granite, tiles and etc...

Introduction

Laser cutting is advanced CNC technology and a unique contactless processing. Laser working without any graphical limits and not produce any mechanical deformation. Laser processing has the advantages of high precision, high speed, no fraying, and high quality results. In addition, applicability of laser processing is more flexible. Laser can do cutting, engraving, hollowing, punching for a variety of textile, fabrics, garment, leather, shoe, upholstery, carpet, automotive interior, tent, etc. Laser processing technology is more sophisticated, creative and unique.

>>>After-sales Service

1. One year guarantee period for product quality. (man made damaged is negotiable).

2. Lifelong maintenance and spare parts supply.

3. Free design of fixtures as customers required.

4. Free training for machines installation and operation of the staffs.

5. Free samples marking of customer provided.

Warmly welcome you visit our factory! ! !

Warmly welcome you contact us directly for more information! ! !

Taishun laser equipment Co., Ltd has been in the field of laser technology development and production for more than 20 years since the company was established, and always stand in the fore front product research and development.

Taishun company has strong Technical force and established set of perfect quality Management system, passed ISO9001: 2008 Quality Management System Certification, BV authentication, SGS and National Mandatory Product "3C" certification, which has reliable quality.

We developed 6 series of more than 10 types laser products which adopt international advanced technology. Such as, fiber laser metal cutting machine, YAG laser metal cutting machine, CO2 laser cutting and engraving machine, Fabric Flatbed laser cutting machine, Conveyor working table machine, laser marking machine and so on.

Taishun laser are good at produced medium and small laser power laser cutting machine, specially to supply one whole sets of laser processing solution scheme and related facilities for customers in plush toys, leather cutting, plush fabrics, automobile, textile, textile clothing, advertising handicrafts, electronics, medical equipment and etc. These laser equipment were widely applied in electronic circuit, auto spare parts, hardware tool, medical instrument, digital products, apparatus and instrument, optic communication component, packing and printing etc. To create a new Second-Generation small power laser cutting machine with more rapid and refinement manufacturing.