Product Specifications

| Prod Model: |

TSGX150300 |

| Laser Type: |

Fiber Laser |

| Laser Power: |

500W |

| Laser Source Type: |

Fiber Laser |

| Applied Material: |

Stainless Steel, Iron, Carbon Steel, Aluminum |

| Applicatioin: |

Kitchenware, Advertising, Gifts, Lighting |

Product Description

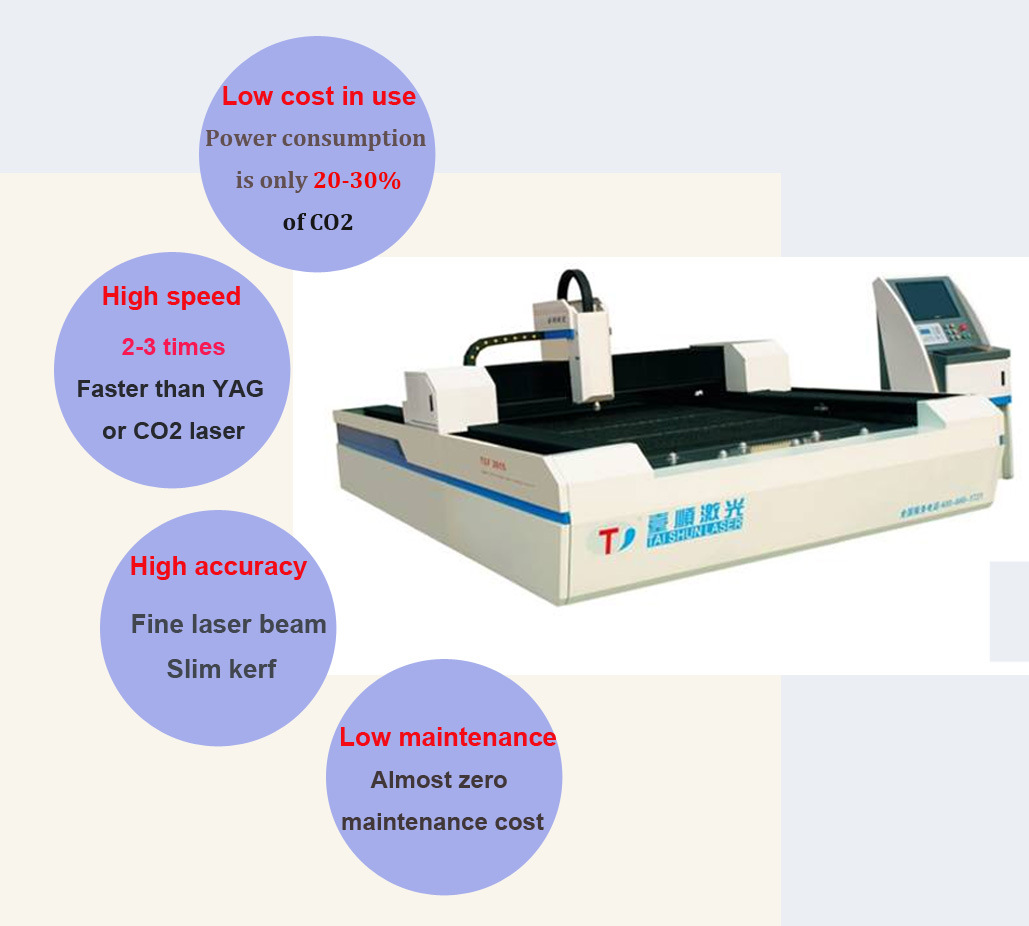

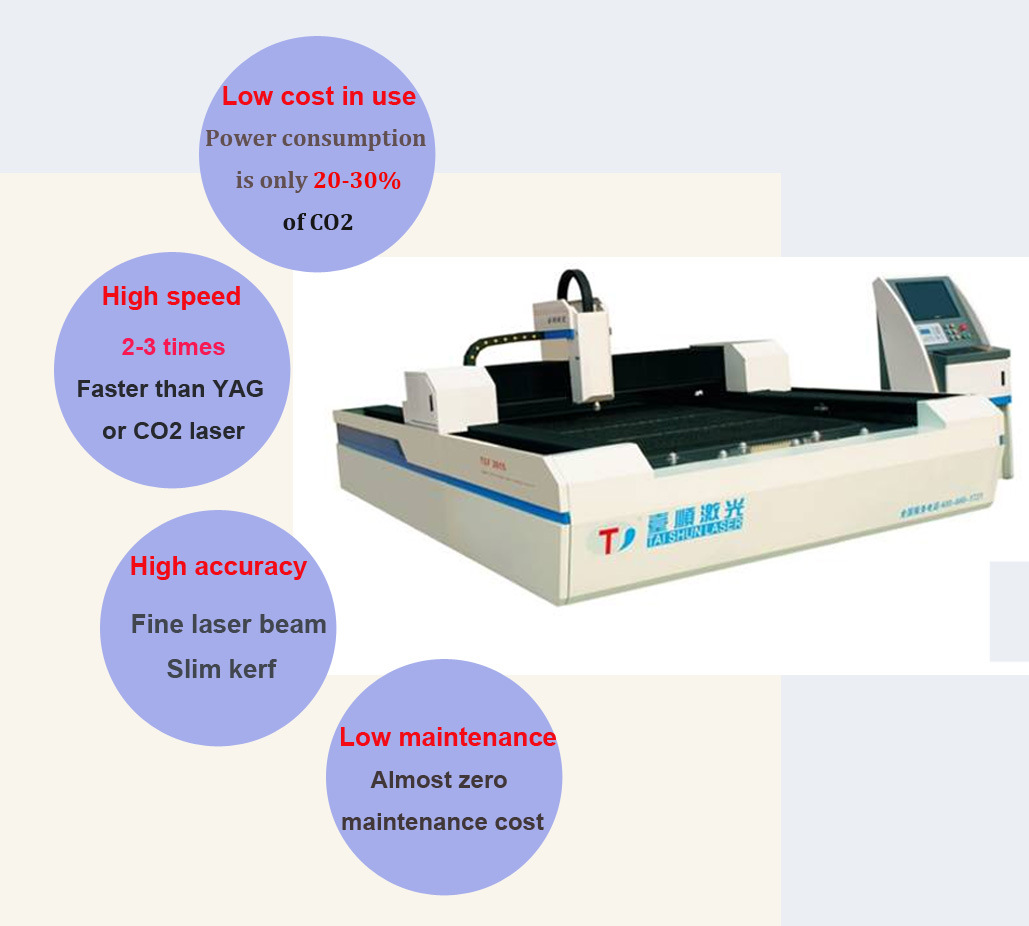

Advantages of the Fiber laser cutter:

1.High Efficiency--The rapid cutting speed is two times higher than ordinary laser cutting machine.

2.Environment friendly--Laser cutting will not creates any gases for the special cutting technology for steel sheet.

3.Lower Consumption--The power consumption of our fiber laser cutter was reduced by 20%-30% compared wtih ordinary laser cutting machine.

4.Maintenance-free--For the fiber laser cutter, the reflect lens are no needed. It will help to save a lot of time when optical path is adjusted. The laser generator with longer lifetime which no need maintaince during usage

Working principle of the Fiber laser cutting machine:

Metal fiber laser cutting machine is adopted metal laser which is using xenon lamp as excitation source and focused the laser on the workpiece surface, the workpieces are there areas of partial melting and moment , move the light irradiation by CNC machine computer control system and automatic punch.

Fiber Laser cutting Machine Application:

Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

Where to use a laser metal cutter

1) Excellent beam quality: Smaller focus diameter and high work efficiency, high quality.

2) High precision and high speed cutting compared with wire cutting

3) Stable running: adopting the top world import fiber lasers, stable performance, and key parts can reach 100,000 hours;

4) High efficiency for photoelectric conversion: Compared with CO2 laser cutting machine,fiber laser cutting machine has three times photoelectric conversion efficiency

5) Low cost: Save energy and protect environment.

6) Low maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7) Easy operations: fiber line transmission, no adjustment of optical path;

8) Super flexible optical effects: compact design, compact and easy to flexible manufacturing requirements.

Paramter:

| Model | TSGX-130250 500W Fiber laser metal cutting machine |

| Work table | saw tooth work table |

| Working area (mm) | 1300x2500 mm |

| Laser power (walts) | Cyrus 500w ( 1000w/ 2000w optional) |

| Laser type | Hermetic co2 glass tube |

| Power supply | AC380 50HZ |

| Position speed | 1800mm/min |

| Locating precision | <0.01mm |

| Resolution ratio | ≤ 4500dpi |

| Control configuration | Cypcut control system |

| Data transfer interface | USB(offline) |

| Cooling way | Water cooling CW 6100 |

| Compatible Software | CorelDraw, Photoshop, AutoCAD |

| Machine packing | Veneer case |

Cutting thickness for 500W

| Thickness (mm) | material | Max cutting speed (m/min) | Aux gas |

| 1 | Carbon steel | 10 | O2 |

| 8 | gas |

| 2 | 3.8 | O2 |

| 3 | 2 |

| 4 | 1.2 |

| 5 | 0.8 |

| 6 | 0.5 |

| 1 | Stainless steel | 8 | air |

| 9 | O2 |

| 2 | 2.5 | air |

| 3 | O2 |

| 3 | 1.8 | O2 |

Guarantee&After-sale service

1, Best components, perfect technics and strictly ex- factory inspection.

2, 1 year guarantee for whole machine.

3, 24 hours (all days) technical support by call ,e-mail, skype or computer

remote control service by engineer.

4, Multi-language software, operation CD and detailed User Manual together with machine.

5, We offer free training in our factory, engineer oversea service is available if you like.

FAQ:

Q1.What's the guarantee for the product quality?

A:We offer one-year free maintenance services for our machines. Fault parts with the valid period will be replaced for free except for consumable parts.

Q2. Is it easy to operate for the new user ?

A: It is very easy ,we offer you operating manual in English ,also our technician can help you via MSN ,Skype or other instant communication tools.If problems in the process of operation,pls keep your lens and mirrors be clean ,then check your laser tube and talk details to us.

Q3. How to maintain the machine?

A: After 3 hours working, it's better close 10 minutes.

B, Keep lens and mirrors clean.

C, The water for laser tube should keep clean and lower temperature, in winter you need input antifreeze.

Q4 .How about the life-span of the laser tube ?

A: If you operate the machine rightly, it can reach to 1500 or 3000hours.(RF metal laser tube can max to 10000hours),It depends on your usage

For example, if it works 8 hours per day, the detailed data as follows:

1, If you set the power at 20%-30% of the total power, the service life is about 1-2years

2, If you set the power at 40-50% of the total power, the service life is about 1 year

3, If you set the power at 70%-80% of the total power, the service life is about 6-8 months

Q5: How can I know the power of the laser tube has been exhausted?

A: you can check the color of the laser beam ,new and strong laser tube is purple when working, otherwise it will be white color.

Q6: Is it harmful to human body when in operation ?

A: It is not harmful, as long as avoid to see it directly

7:How to distinguish laser tubes with different powers and applications?

A: 1. Laser tube length(relatively speaking, the longer, the bigger/stronger)

2. Laser tube diameter(relatively speaking, the thicker,the stronger)

3.The machine with bigger laser tube can cut deeper&more quickly, also its light spot is bigger, So, it is better to choose low-power for engrave, such as 40w, 50w, or 60w and strong power for cutting.

Notice:

Please let us know following informations:

1. What materials you want to cut ?

2. What is the mostly used thickness and what is the maximum thickness?

3. What is the MAX dimension of your materials ?

4. After cutting, what will be the metal used for?

5. Are you an end user or retailer?

According to your above information,we'll recommend the most suitable machine to you.

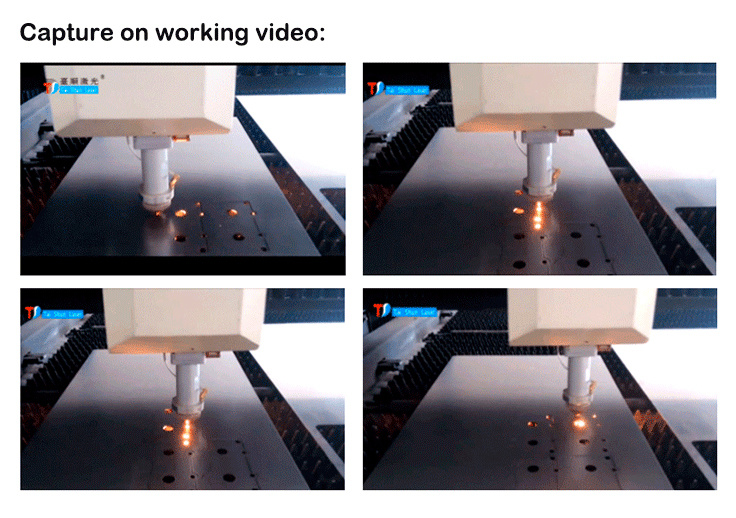

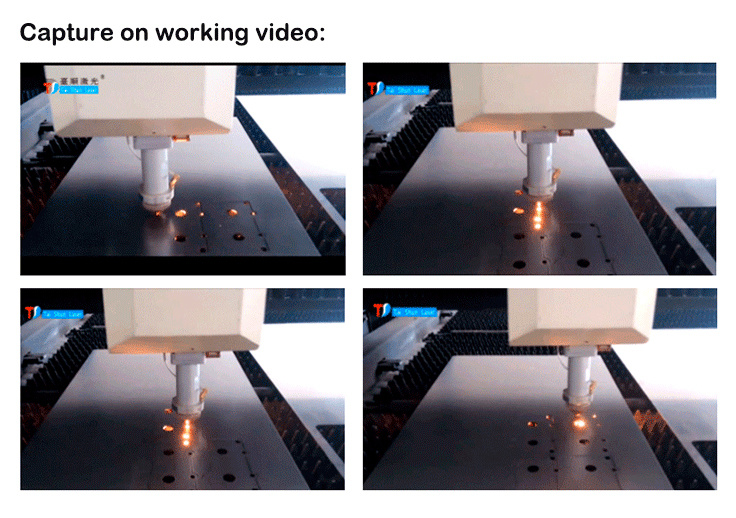

Video channel:

http://v.youku.com/v_show/id_XNTc3OTgyODA0.html?from=s1.8-1-1.2 laser cutting 1mm stainless steel application

http://v.youku.com/v_show/id_XNTg4MDU4ODM2.html?from=s1.8-1-1.2 laser cutting grooving round tube application

http://v.youku.com/v_show/id_XNzE1ODYwNzk2.html?from=s1.8-1-1.2 laser cutting steel sheet application

Taishun laser equipment Co., Ltd has been in the field of laser technology development and production for more than 20 years since the company was established, and always stand in the fore front product research and development.

Taishun company has strong Technical force and established set of perfect quality Management system, passed ISO9001: 2008 Quality Management System Certification, BV authentication, SGS and National Mandatory Product "3C" certification, which has reliable quality.

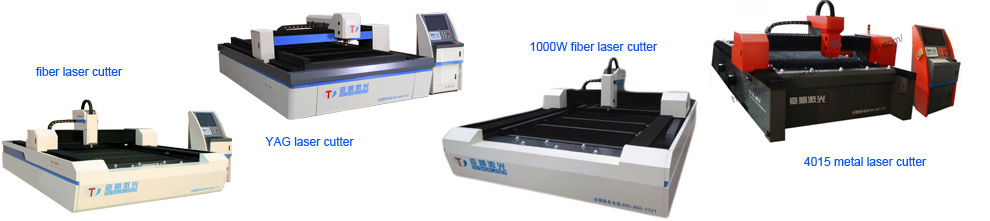

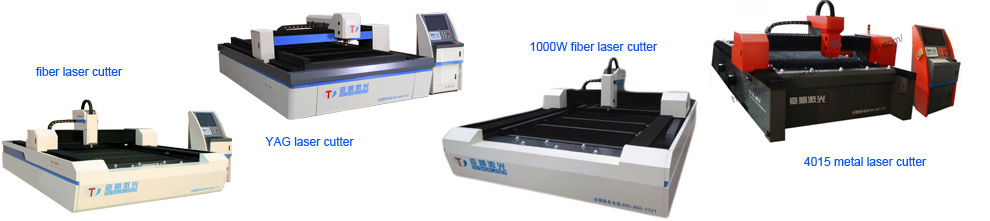

We developed 6 series of more than 10 types laser products which adopt international advanced technology. Such as, fiber laser metal cutting machine, YAG laser metal cutting machine, CO2 laser cutting and engraving machine, Fabric Flatbed laser cutting machine, Conveyor working table machine, laser marking machine and so on.

Taishun laser are good at produced medium and small laser power laser cutting machine, specially to supply one whole sets of laser processing solution scheme and related facilities for customers in plush toys, leather cutting, plush fabrics, automobile, textile, textile clothing, advertising handicrafts, electronics, medical equipment and etc. These laser equipment were widely applied in electronic circuit, auto spare parts, hardware tool, medical instrument, digital products, apparatus and instrument, optic communication component, packing and printing etc. To create a new Second-Generation small power laser cutting machine with more rapid and refinement manufacturing.