Product Specifications

| Prod Model: |

HD-50TST |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Mid East,Eastern Asia,Western Europe |

| Controller: |

Oyo-8226 LCD Touch Screen |

| Refrigeration: |

Cascade Refrigeration System |

| Interal Dimension: |

(W* H* D)40* 50* 40cm |

| Damper Device: |

Forced Air Drived Damper |

| Cooling Method: |

Air |

| Simulated Load IC: |

5.0kg |

| Preheating Time: |

30min |

| Precooling Time: |

60min |

| Senor: |

T* 4 |

| Output Mode: |

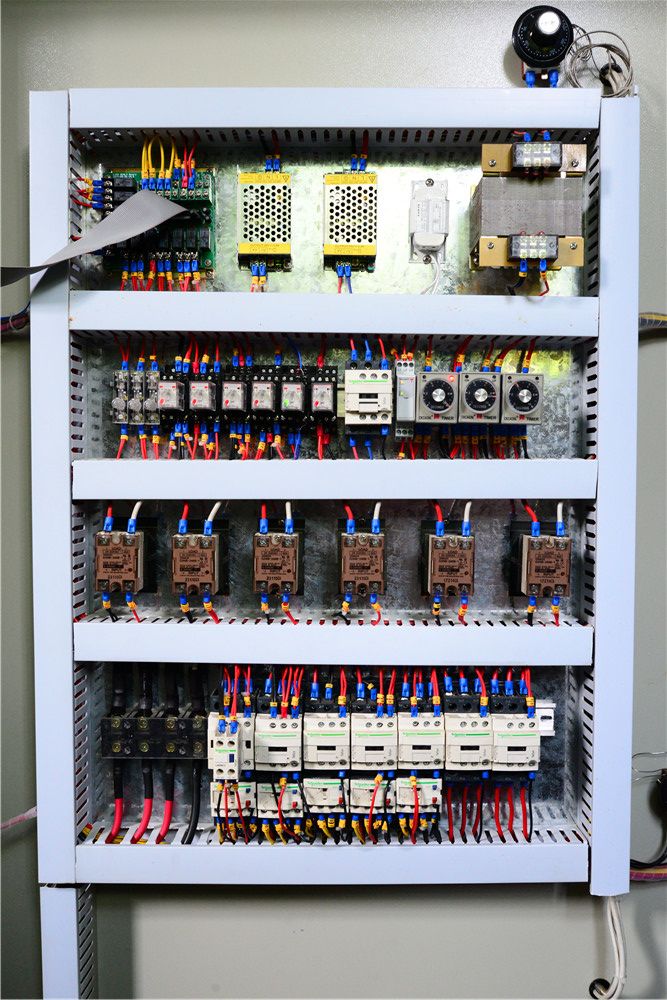

Pid SSR(Control Method) |

| Weight: |

100-500Kg |

| Power Source: |

AC220V |

| Type: |

High Low Temperature Testing Machine |

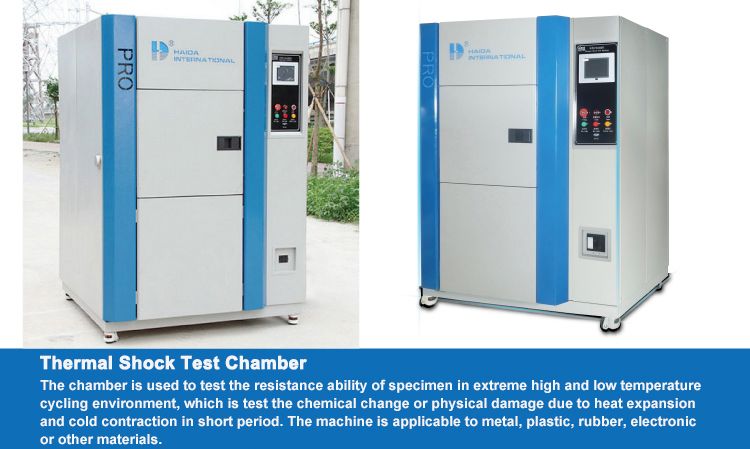

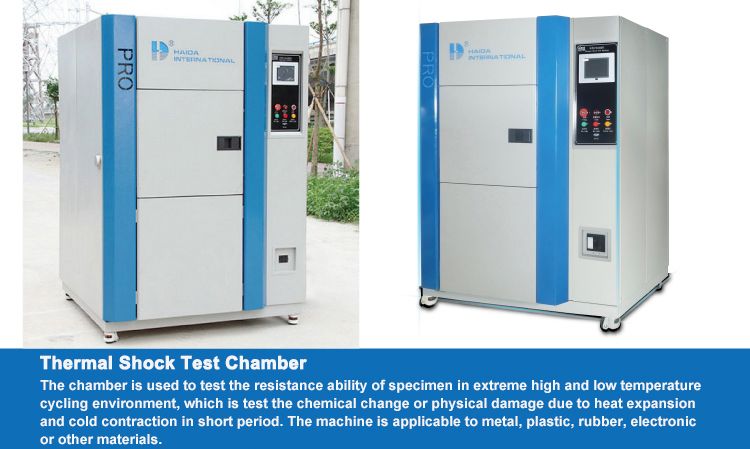

Product Description

Electronic High Low Temperature Testing MachineDescription:Programmable High low Temperature impact tester, used to test the bearing extent of the material structures and composite material in an instant and continuous high temperature and extremely low temperature environment, that is in the shortest time to test its thermal expansion and contraction caused by chemical change or physical harm. Application objects, including metal, plastic, rubber, electronics. And other materials can be used as a basis to improve their products or reference.

Features:1. The machine is divided into three sections: The high temperature chamber, the low temperature chamber and the testing chamber.

2. The color touch panel control system was made in Japan can display Chinese / English. The big size liquid-crystal LCD has been adopted.

3. High formula memory capacity may be set to 120 patterns. The maximum cycle setting is 9999cycles. The maximum setting of each section is 999 Hrs 59 Mins.

4. Provide with RS-232C communication interface device, capable of controlling / editing/ recording in the linkage with the computer and two set dynamic connection point and convenient application.

5. Both 2 zone and 3 zone shocks can be chosen.

6. All equipment is fully automatic, and all process are precisely controlled with P. L. C. 'S.

7. Of any part of the malfunctions, the machine will automatically shuts down and a warning light switches on.

8. Machine can be shut down automatically in case of electrical power instabilities.

Main Parameter:| Interal Dimension | (W× H× D)40× 50× 40cm |

| Structure | Two chambers design(the hot chamber or the cold chamber) |

| Damper device | Forced air drived damper |

| Interior material | SUS# Stainless steel plate |

| Exterior material | SUS# Stainless steel plate |

| Basket material | SUS# Stainless steel plate |

| Refrigeration | Cascade refrigeration system |

| Cooling method | Air |

| Ambient temperature | 0° to 30° |

| Preheating temperature | +60.00º C to +200.00º C |

| Precooling temperature | -10.00º C to -70.00º C |

| H. T. Shocking | +60.00º C to ++50.00º C |

| L. T. Shocking | -10.00º C to -65.00º C |

| Temperature range(optional) | A: -40º C to 150º C B: -55º C to 150º C C: - 65º C to 150º C |

| Temperature uniformity | ± 2.00º C |

| Simulated load ic | 5.0kg |

| HT IN-Zone | -65.00º C to +150.00º C/5min |

| LT IN-Zone | +150.00º C to - 65.00º C/5 min |

| Preheating time | 30MIN |

| Precooling time | 60MIN |

| Senor | T× 4 |

| Controller | OYO-8226 |

| Setting range | Temperature: -100.00º C to +200.00º C/TIME: OHIM to 999H/CYCLE: 0 to 9999 |

| Resolution | Temperature: 0.1º C |

| Output mode | PID SSR(control method) |

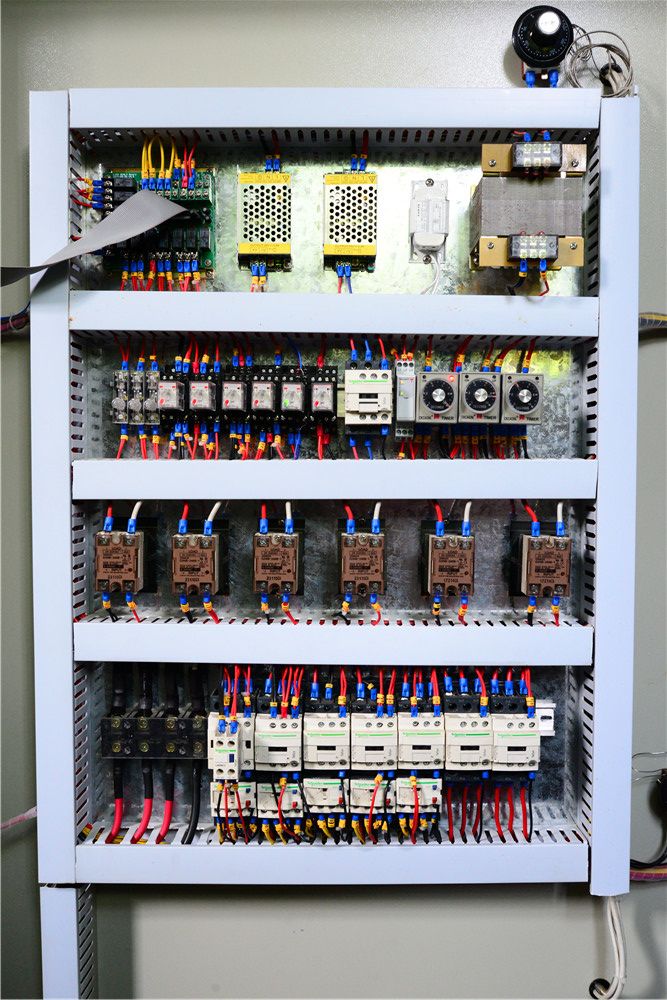

| Power(K. W) | AC380V 50Hz 18K. W |

High temperature chamber:

Heater: NI-CR alloy electric heater

Draught fan: Share centrifugal fan when high temperature and do environmental temperature, preheating with axial flow fan.

Low temperature chamber:

Cooler: Fin cooler, regenerator

Draught fan: centrifugal fanRefrigerating device:

Cooling method: mechanical compression refrigeration

Refrigeration compressor: Semi-closed piston

Refrigerant: R23/R404A

Condensation: Stainless steel welded plate heat exchangerAdditional functions:

Timer, over temperature and power failure protection, alarm, record test curve, emergency stop, display test time

Circulated cooling water: pressure: 0.2~0.4MPa, temperature: ≤30ºC

Standard configuration: indication lamp of test chamber, time meter, test hole for wire routing, 6pcs castor, 4pcs adjust wheel.

The introduction of Haida

The introduction of Haida

Haida products are widely used in paper products, packaging, ink printing, adhesive tapes, bags, footwear, leather products, environment, toys, baby products, hardware, electronic products, plastic products, rubber products and other industries, and are applicable to all scientific research units, quality inspection institutions and academic fields. Our products meet UL, ASTM, JIS, GB,SO, TAPPI, EN, DIN, BS and other domestic and international standards.

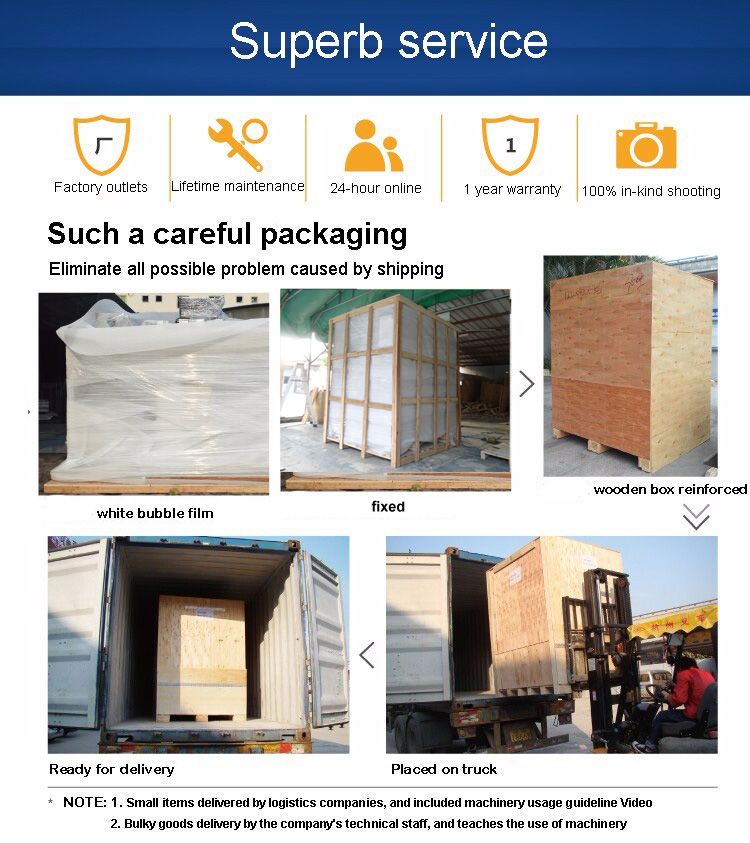

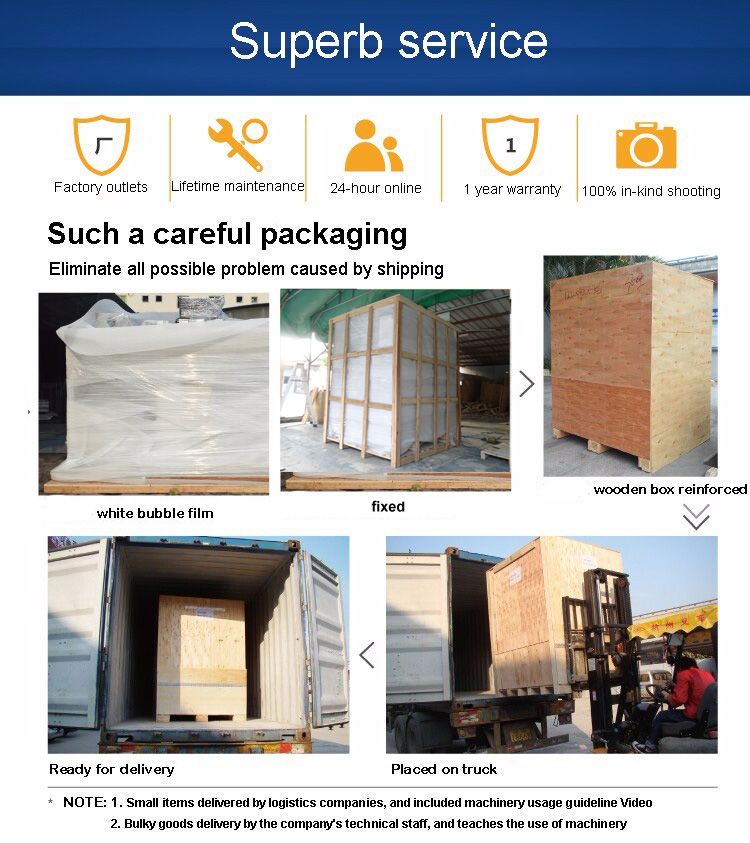

Packaging & Shipping:

Simulation Animatronic Customer Triceratops are covered with air bubble film before put them into the wooden case, which not only has good shock absorption, impact resistance, heat sealing and also has the advantages of nontoxic, odorless, moisture corrosion, good transparency etc.

After-service:

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation muanual. We can provide video-con.

Haida International Equipment Co., Ltd., is headquartered in Taichung. As a comprehensive manufacturer of precision detecting instruments, Haida has contributed to the development of global industry for a long time. In order to better serve clients in mainland China, our company set up factories and offices in Dongguan in the early 21st century. Haida products are widely used in paper products, packaging, ink printing, adhesive tapes, bags, footwear, leather products, environment, toys, baby products, hardware, electronic products, plastic products, rubber products and other industries, and are applicable to all scientific research units, quality inspection institutions and academic fields. Our products meet UL, ASTM, JIS, GB, ISO, TAPPI, EN, DIN, BS and other domestic and international standards.

With advanced processing equipment and exquisite manufacturing technology, our company focuses on human resource development and maintenance and cultivates a strong R&D and manufacturing team, thus providing a strong guarantee for the manufacture of high-quality products. We have always insisted on the principle of "quality first, sincere service". According to customers' needs, we constantly challenge ourselves to be excellent and promote the development of our company. We wish to cooperate with customers all over the world based on mutual integrity. Company Services: Adhering to the business philosophy of "Quality comes from precision; Quality creates the future", all Haida employees serve each client actively and conscientiously in order to meet full customer satisfaction.