Product Specifications

| Prod Model: |

LFJS-ZrC |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Name: |

Tungsten Carbide Powder, Cemented Carbide Powder |

| Application 1: |

Carbide Inserts, End Mill, Drill Bits, Milling Cutter |

| Application 2: |

Coation Hard Thin Film Atomic Energy Spray Coating |

| Application 3: |

Ultra-Fine Grain Hard Alloy Metallurgy Automation |

| Application 4: |

Rocket Nozzle, The Atmosphere Space Rocket Nose Con |

| Application 5: |

Coating Powder and Thermal Spraying Additive |

| Has Been Finished Wolfram Tungsten Rod: |

Hard Refractory Ceramic Material, Cermet Material |

| Particle Size: |

0.5-500 Micron, 5-400mesh |

| Unique Advantages: |

Patent Technology, Patent Number |

| Classification: |

Metal Carbide Powder |

Product Description

Features: High temperature oxidation resistance, high strength, high hardness, good thermal conductivity and toughness. enhance the hard alloy the intensity;

What It Is?

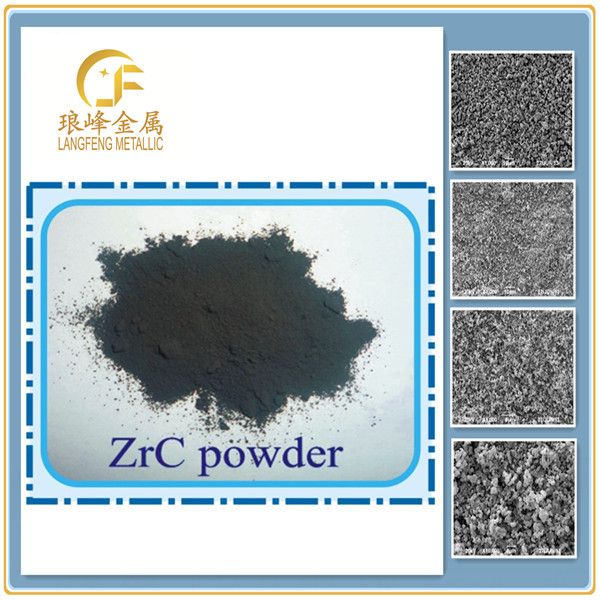

Zirconium Carbide Powder

Zirconium carbide (ZrC) is an extremely hard refractory ceramic material. It has the appearance of a gray metallic powder with cubic crystal structure. It is highly corrosion resistant. This Group IV interstitial transition-metal carbide is also a member of ultra high temperature ceramics or (UHTC). Due to the presence of metallic bonding ZrC has thermal conductivity of 20.5 W/m·K and electrical conductivity (resistivity ~43 μΩ·cm) similar to zirconium metal. Strong covalent Zr-C bond gives this material very high melting point (~3530 °C), high modulus (~440 GPa) and hardness (25 GPa). ZrC has lower density (6.73 g/cm3) compared to other carbides like WC (15.8 g/cm3), TaC (14.5 g/cm3) or HfC (12.67 g/cm3). ZrC reacts with water and acids and is pyrophoric.

Formula: ZrC |

Purity: 99 - 99.8% |

Carbon: 11.2% |

Free Carbon: 0.3% |

Formula Weight: 103.22 |

Density: 6.73 gm/cm3 |

Melting Point: 3540oC |

Boiling Point: 5100oC |

Mohs Hardness: 2600 Kg/Mm2 @ 20oC |

Electrical Resistivity: 70 Micro ohm-cm |

Crystal Structure: Cubic |

Form: Powder, typically -325 mesh |

Where Is Range Of Application?

1, A raw material of solid propellant

2, Production of alloy steel

3, A raw material of cemented carbide

4, Used as abrasive

5, raw materials of metal zirconium and zirconium tetrachloride

6, A kind of promising fine ceramic materials

Why Choose Langfeng?

a) Best Quality

As a science & technology manufacture,our priority has always been providing our clients with great quality products. We have got patent technology for some items.

b) Best Service

We offer technical support before and after selling,and a certain amount of free sample. And 24 hours technical support by e-mail or call.

c) Best Price

We are manufacture of powder metallurgy direct!

Our factories, logistic team,designers and technicians have been working closely together to supply our customers with the best in terms of pricing, manufacturing, technical support and designing!

Changsha Langfeng Metallic Material Co.,Ltd is a science and technology of powder metallurgy, own a strong R & D team. Main produce:

1.TiCN based Cermet rods/ blank((Patent item,very suitable as cutting tools for various steel finish machining)

2.Carbide powder: Titanium carbide (TiC), Zirconium carbide (ZrC), Hafnium carbide (HfC), Vanadium carbide (VC), Chromium carbide (Cr3C2) ; Molybdenum carbide (Mo2C), Niobium carbide (NbC), Tantalum carbide (TaC); 3.Compound carbide powder (Ta,Nb)C,(W,Ti)C,(Ti,Ta)C powder etc;4.Tile/glass cutter/ cutting wheels; 5.Planetary ball mill machines and industrial microwave oven;FAQ.1.Can I negotiate the Prices? Yes, we may consider discounts for bulk orders of individual products. 2.How about your sample and MOQ ?For carbide metal powder in D50 3- 5 micron/, 200g free sample could be provided, freight collected; For carbide powder in D50 0.8-1.5micron, 2kg paid sample is needed for good handling in proportion and quality control;For compound carbide powder (CK material),

20-50kg paid sample is need for good handling in proportion and quality control;3. How long will it take to execute my order? For the stock items, we can arrange the shipment within 3- 5 days after received your payment. For the customized items, we will indicate the delivery time in the quotation sheet. 4. How about your production leading time ?For carbide metal powders, 7-10 working days;5.What's the key point for me to buy your product?Factory direct price and highest quality powder to help satisfy your customers.

Contacting us to get latest imformation and quotation!

Free sample is acceptable!

Mob: 86-15111029656

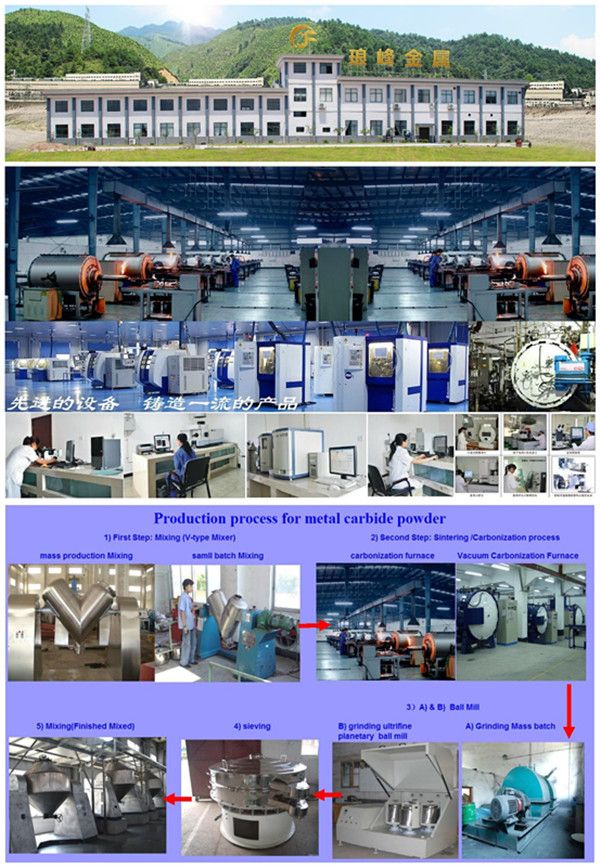

Changsha Langfeng Metallic Material Co., Ltd, founded in 2009 Changsha Long-ping High-Tech Park, is an patent-owning firm specializing in metal carbide powders' research, production and sale.

With 100 sets of various manufacturing equipments covering the process of raw material mixing, carbonization, sintering, grinding, sieving, mixing and packing, the group distinguishes itself also by 182 workers and 2 academician in engineering material from Chinese Academy of Science. Furthermore, we established technical support relationship with Powder Metallurgy Research Institute of Central Sounth University and Changsha Research Institute of Mining And Metallurgy.

Our products: Metal carbide powder, multiple carbide powder, compound powder, Ti(C, N) Based cermet, Tungsten carbide tile cutter, glass cutter wheel, planetary ball mill, industrial microwave furnace.

Our goal:

In the next five years, we face the task of expanding investment of US$80 million. In 2023, a new R&D base for new materials will be established, and sales revenue goal is US$10 billion.

Company culture:

Vision: Driving force in technical progress

A world leader in the field of new materials

Mission: Create value for the whole world

Operation idea: Good faith, high quality, innovation, win-win

Serve concept: Warm, excellent, quick and considerate services.

Spirit: Never give up, Never stop

Team work, make dream come true;

Value: Quality win honor, service win reputation;

Responsibility: Create value for customers, set up developing stage for staff.

We guaranteed products at a competitive price and high quality. At present, our products have a very good sale in domestic and overseas market. We wish to cooperate with you to create a bright future and mutual benefit. Much appreciation for your prompt attention in advance, we are eager to look forward to hearing from you soon.