Categories

Categories

| Price: | US $ 6.5-36/Piece |

|---|---|

| Min Order: | 200/Piece |

| Pay Type: | T/T,Western Union,Money Gram |

| Product Name: | Dust Collector Venturi Filter Bag Support Cage |

|---|---|

| Usage: | Matched with Filter Bag |

| Types: | Round Style/Flat Style/Envelope Style/ Special Sty |

| Number Of Wires: | 8/10/12/16/20/24 Vertical Wires |

| Ring Space: | Ring Spacing Standard Is 6 Inch or 8 Inch.(15.24cm |

| Cage Diameter: | Cage Diameters Range From 4 Inch to 8 Inch (100mm |

| Wire Thickness: | 2~5 mm |

| Material: | Carbon Stee, Galvanized Steel, Stainless Steel |

| Finishment: | Epoxy, PVC Vinyl Coating |

| Packaging: | Cages Are in Bulk in Container or in Steel Frame I |

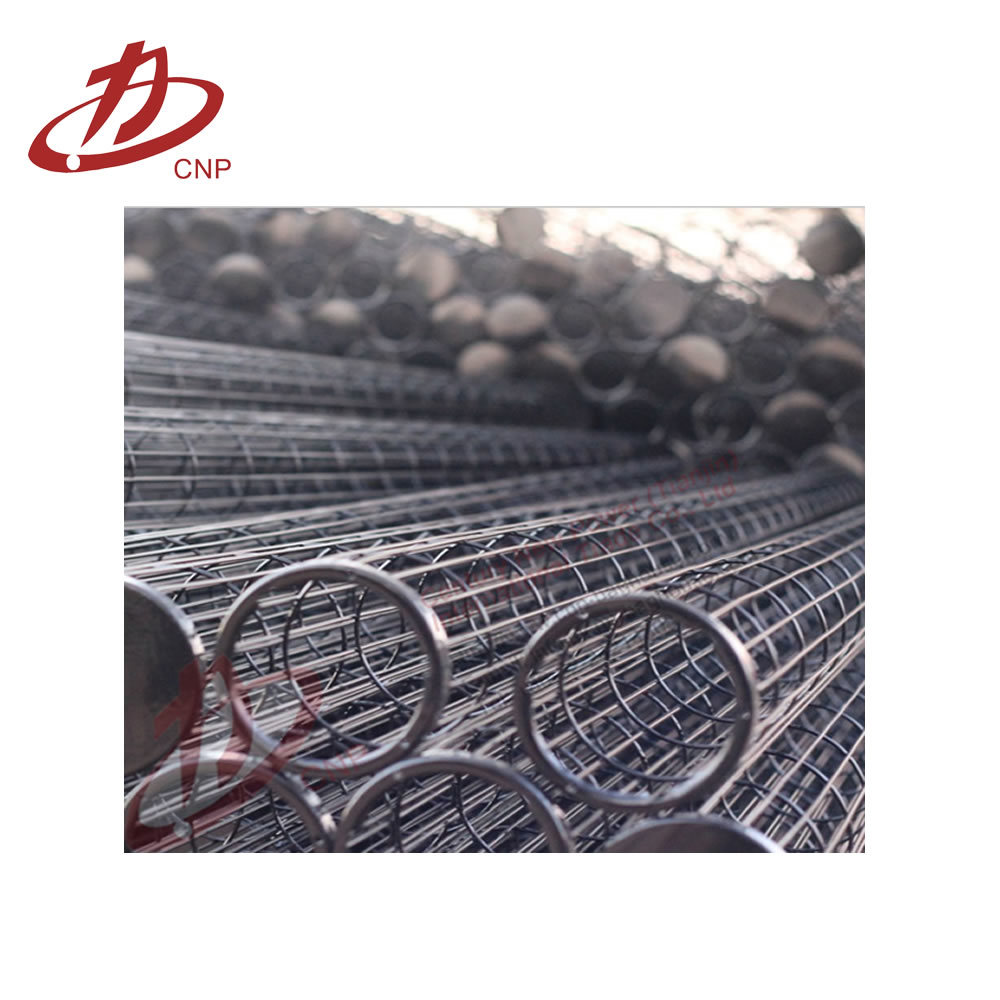

INTRODUCTION

The dust air flow is from filter bag's outside to inside when the Pulse jet bag filter equipment on working. So, the filter bag must needs the frame (filter cage) for supporting and hold their shape.

Filter cage manufacture

We make filter cages of different shapes and dimensions to meet customers' requirements. To supply with perfect testing for our products. Our cost is under utmost lower control because of our assembly line production. Precise, pragmatic and prudent working styles are adopted in every working procedure at CNP. We are highly responsible for every product component In addition, advanced manufacture equipment and scientific management made each finished product become the first selection of customers. By offering reliable assurance to integrate product quality with international standards with advanced equipment and technology, Professional production of dust cage skeleton, and can also design, develop, and manufacture as the clients request.

By offering reliable assurance to integrate product quality with international standards with advanced equipment and technology, Professional production of dust cage skeleton, and can also design, develop, and manufacture as the clients request.

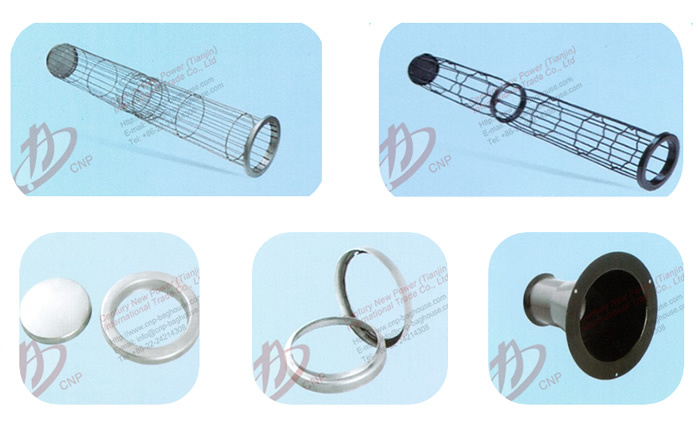

Specifications for Filter cages

Types: Round Style/Flat Style/Envelope Style/ Special Style

Number Of Wires: 8/10/12/16/20/24 vertical wires

Ring Space: Ring spacing standard is 6 inch or 8 inch.(15.24cm or 20.32cm)

Cage Diameter: Cage diameters range from 4 inch to 8 inch (100mm to 200mm)

Wire thickness: Wire thickness ranges are 2mm to 5mm

Material: Carbon Stee, Galvanized Steel, Stainless Steel

Finishment: Epoxy, PVC vinyl coating

Packaging: Cages are packed in custom designed cartons

Usage: Dust from factory of mine, wood,Cement, chemical, medicine, dying,Paint, plastic, food & other industry,such as coal fired power stations, Steel Power station, Cement industry, Paper industry & other Industrial Segments.

Advantages:

1. no corrosion

2. no damage

3. 3-5 times longer life than other bag Cage with steel

4. economical maintenance(almost no Maintenance required)

5. prominent effect in removing dust from Filter by pulsing

6. easy to install

7. no ventury installation required

Working occasions

In industry dust collection

Power Stations

Filtered dust

Flue ash, discharging flue ash

Coal dust

Building and Construction

Cement, furnace dust, gypsum, limestone, finely ground quartz,

Calcium hydroxide, lead monoxide, quicklime, acid crystals,

Pure clay, phosphates, magnesite concentrate, finely ground

fluorid, production of aluminum

Chemical Industry

Thomas meal (Fertilizer)

Rubber compounds, sinter dust, catalysts

Sodium sulfate

Soap powder

In machinery top:

Silos / Tanks

Discharging systems

Warehouse units

Mixing equipment

Homogenizing systems

Chute Bottoms

Conveyor systems

Ventilator systems

Aeration systems

Powder Coating Machinery

Bottoms for sinter basin