Categories

Categories

| Price: | US $ 2.95-6.5/Piece |

|---|---|

| Min Order: | 50/Piece |

| Pay Type: | L/C,T/T,D/P,Western Union,Paypal |

| Product Name: | Asphalt Plant Replacement Dust Filter Sleeves |

|---|---|

| Filter Material: | Polyester, PP, Nomex, Fiberglass, PTFE, P84, etc. |

| Area Gram Weight: | 500 G/M2 or More |

| Filtration Direction: | Surface Filter |

| Dust Cleaning Type: | Pulse Jet Clean |

| Applicable: | Pulse Jet Baghouse |

| Proposed Filtering Speed: | No More Than 1.4 M/Min |

| Diameter & Length: | Customized |

| Temperature Resistance: | Max 280 Degree |

| Warranty: | 1~3 Years |

| Material: | Non-woven |

| Medium Material: | Synthetic Fiber |

| Type: | Pocket Filter |

| Usage: | Air Filter |

| Filtration Grade: | HEPA Filter |

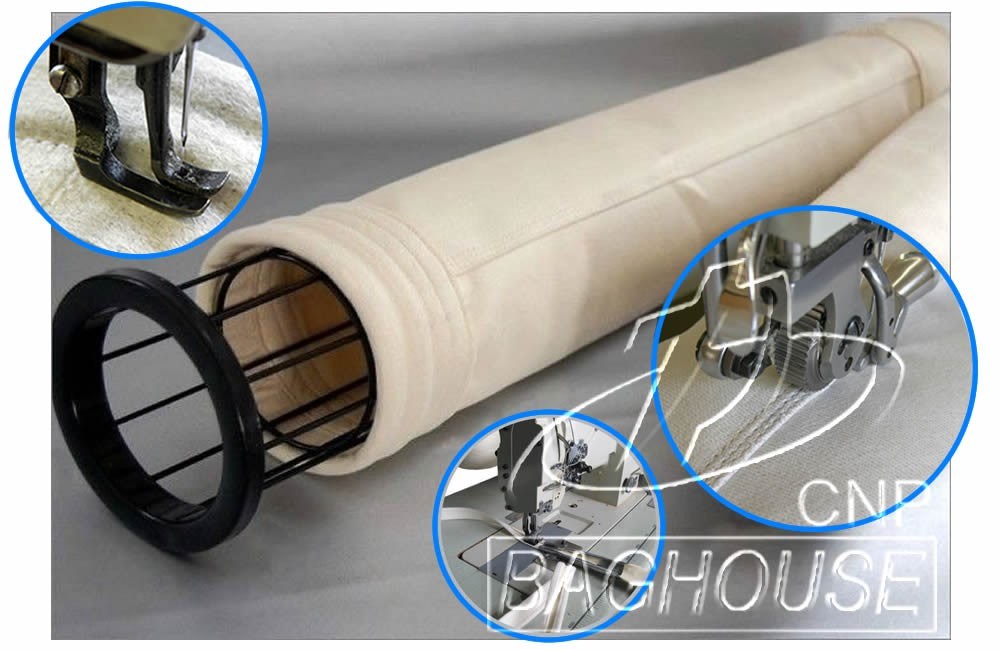

The filter bag sewing need attention:

Filter bag sewing material should be the same as the material of filter material. In special circumstances, we will adopt to use different filter material of sewing thread, the suture properties such as strength, heat resistance and chemical resistance should be better than the filter material sewing thread.

The filter bag stitching line:

Filter bag bag body vertical stitches must be strong, straight, and shall not be less than three line. The bag top and bottom according to different requirements with single or double needle stitching. Filter bag suture needle closely related to the filter bag material, not only to ensure the stitching rigor and suture strength not leak dust, but also shall not damage the strength of the filter material itself.

The Needle density of chemical fiber filter material filter bag should within 10 cm length (25 + / - 5) needle; Glass fiber filter material filter bag needle density can not too large. The stitching width normally for 9 ~ 12 cm. The stitches and distance on the edge of the filter material: needled felt for 2 ~ 3 mm, glass fiber filter material is 5 ~ 8 mm.

Filter bag should be according to the design requirements for inspection and repair after sewing, eliminate surface crease, dirt and grease. For PTFE coated filter bag, in addition to the needle density control and strict operating procedures, it needs to use special materials for all the pin hole repairing.

In industry dust collection

Power Stations

Filtered dust

Flue ash, discharging flue ash

Coal dust

Building and Construction

Cement, furnace dust, gypsum, limestone, finely ground quartz,

Calcium hydroxide, lead monoxide, quicklime, acid crystals,

Pure clay, phosphates, magnesite concentrate, finely ground

fluorid, production of aluminum

Chemical Industry

Thomas meal (Fertilizer)

Rubber compounds, sinter dust, catalysts

Sodium sulfate

Soap powder

In machinery top:

Silos / Tanks

Discharging systems

Warehouse units

Mixing equipment

Homogenizing systems

Chute Bottoms

Conveyor systems

Ventilator systems

Aeration systems

Powder Coating Machinery

Bottoms for sinter basin

Filter Material Specification:

| Filter bag material | Working temperature | Chemical properties | Application 1 | Application 2 |

| Polypropylene needle felt | up to 90 degree | Good for Acid and Alkali gas | Grain | High chemical gas and less temperature |

| Polyester needle felt | Up to 130 degree | Good for Acid and nomal for Alkali | Every Dust Collection | Temperature lower than 130 degree |

| Acrylic needle felt | Up to 130 degree | Good for Acid and Alkali gas | Every Dust Collection | Chemical stronger than polyester suitalbe |

| Nomex needle felt | UP to 200 degree | Good for Acid and nomal for Alkali | Asphalt | Cement dust |

| PPS (Polyphenylene Sulphide) Needle felt | Up to 190 degree | Good for Acid and Alkali gas. Bad for Oxygen | Coal fired dust gas | Sulphur |

| P84 (Polyimide) Needle felt | Up to 240 degree | Good for Acid and Alkali gas | Incineration | Temperature lower than 240 degree |

| PTFE (Polytetrafluoroethylene) needle felt | Up to 260 degree | Good for Acid and Alkali gas | Mixed Chemical gas | Temperature lower than 260 degree |

| Glass fiber woven bulk yarn | Up to 280 degree | Good for Acid and Alkali gas | Cement kiln | Coal fired dust gas |

| Glass fiber mixed needle felt | Up to 280 degree | Nomal for Acid and Alkali gas | Acid gas | Temperature lower than 280 degree |

CNP Co., Ltd. was founded in 2008, specializes in the field of air pollution control and bag filters. Including engineering design, planning, consulting, equipment research and development, manufacturing, sales, installation and commissioning, as well as production and services.

Based on the high starting point, CNP Co., Ltd., with a positive and upward pioneering spirit, will further create brilliancy as to technological innovation, intellectual property rights and independent brand strategy.