Vacuum Packing Machine for Pickles, Snacks

| Price: |

Negotiable/Piece |

| Min Order: |

1/Piece |

| Pay Type: |

T/T |

Product Specifications

| Prod Model: |

MR8-200ZK |

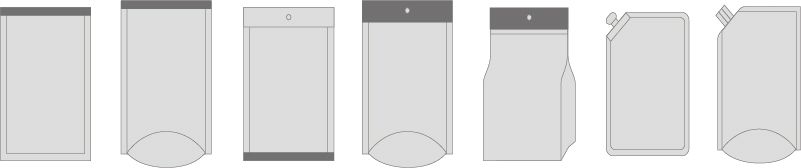

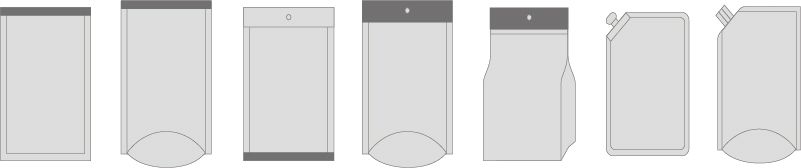

| Pouch Type: |

Stand-up Pouches, Zipper Bags,Paper Bag, etc |

| Bags Size: |

W: 100-200mm L: 120-300mm |

| Filling Volume: |

20-1000g |

| Capacity: |

10-40bags/Min |

| Dimension: |

2600*1900*1700mm(L*W*H) |

| Weight: |

3000kg |

| Automatic Grade: |

Automatic |

| Application: |

Dairy Products |

| Driven Type: |

Electric |

| Material Type: |

Solid |

| Packaging Material: |

Composite Materials |

| Packaging Type: |

Pouch |

Product Description

Quick Details| Model | MR8-200ZK |

| Function | Pouch filling/ sealing machine

Spout pouch packaging machine |

| Pouch type | Four(Three)-side sealed pouch,Stand-up(Doy pack) pouch,Spout pouch etc. |

| Pouch Size | W: 100-210mm L: 120-300mm |

| Filling Volume | 20-1000g (depending on type of products) |

| Capacity | 10-40 bags/min |

| Package Error | ≤±1 |

| Dimension | 2600×1900×1700(L*W*H) |

| Weight | 3000KG |

| Compress air condition | ≥0.6m³/min supply by user |

Features and Characteristics| - The machine can pack different products which need vacuum packing |

| - Automatic rotary vacuum packaging consists of filling system and vacuum system. The former is intermittent, the latter incessant |

| - Quick change-over, the height of automatic bag feeding device can be adjusted automatically |

| - Comply with the sanitation requirements of food processing machines. Materials contact parts adopt 304 stainless steels, or other materials complying with food hygiene requirements to ensure foof hygiene and saferty. |

| - The machine is easy is easy to wash down |

| - The machine adopts premade pouches with a complete pattern, a high-quality sealing, resulting in improved product quality and grades |

| - Easy to operate. The machine adopts PLC and POD (touch screen)electrical control system, with a friendly man-machine interface. No sealing will happen if no filling occurs, causing bags not filled to be recycled, thus no bag wasted. |

| - Sealing temperature detection, Alarm system will be started, if heating pipe is damaged |

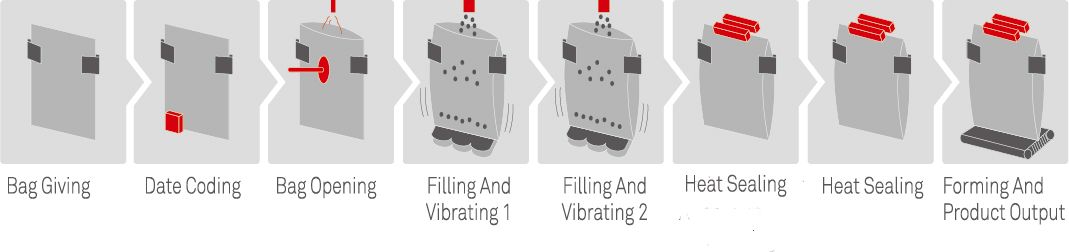

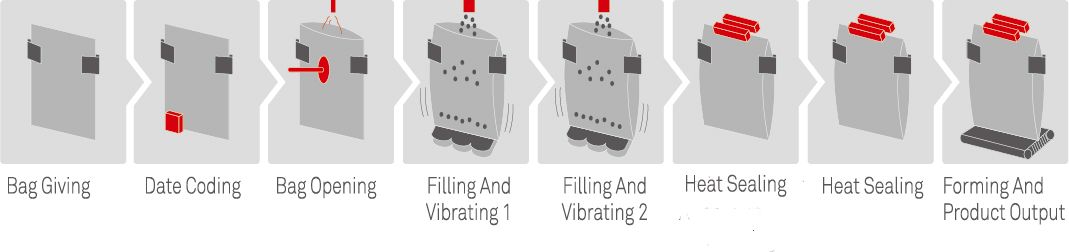

Standard Equipment Part| 1. Date printer |

| 2. PLC control system |

| 3. Pouch opening devices |

| 4. Vibrating device |

| 5. Cylinder |

| 6. Magnetic valve |

| 7. Temperature controller |

| 8. Vacuum pump |

| 9. Frequency convertor |

| 10. output system |

| 11. Vacuum chambers |

Application| puffed food, candy, biscuit, peanut, cookies, pistachio, crystal candy, brown sugar, daily commodities, cooked food. pickles |

Optional Configuration| material weighing & filling machines, platform, check weigher, material elevator, finished product conveyor, metal detector |

Work Process Pouch Type

Pouch Type

Hangzhou Merry Sino Technology Co., Ltd, based in Hangzhou (China), has been a provider of automatic rotary packing machines and vacuum rotary packing machines since 2000, with our plant in Ruian, Wenzhou. As a national high-tech enterprise, we combine 18 years of experience in the industry from research to development, production, sales and service. We also have the industry's largest research and development center, a better production system, and a huge network for marketing and service. Thus we are at the top of the industry at home in terms of annual production capacity and market share.

At present, our marketing network has spread over the world, with some machines exported to foreign areas and countries, including Europe, USA, Southeast Asia, West Asia, and the Middle East. Our machines are widely used for packing food, pharmaceutical products, cosmetics, chemical products, and household products. As a result of more than 10 years of technological accumulations and innovation, we have been granted 8 patents and become the leading enterprise in China to manufacture automatic rotary packing machines. With improved high quality, our products are well received by customers both at home and aboard.

We have been following the principle of Superior Quality, Users as God, Credible Service, and Continuous Improvement. A mission to build China's most stable packaging machines is what sets Merry Sino apart from the competition. We are the first in the industry to pass ISO 9001 quality management system certification and CE certification. In future, we will forge ahead with technology, enterprise system, management, and enterprise culture to test your stand with our superior quality and good market reputation.