Taian Crystal High Precision Diamond Cutting Alloy Wheel Repair Machine Wrm2840

| Price: |

US $ 14000/Piece |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T,Western Union |

Product Specifications

| Prod Model: |

WRM2840 |

| Type: |

Horizontal Lathe |

| Power Source: |

Electric |

| Controlling Mode: |

CNC |

| Automatic Grade: |

Automatic |

| Setting Mode: |

Floor-type |

| Precision: |

High Precision |

| Tool Holder: |

4 |

Product Description

Product Application

PC Wheel repair machine is our company's latest research and development of new wheel repair machine. It is a special lathe for repairing the car aluminum wheel surface scratch.The surface curve of the wheel hub is detected by the high precision touch probe, Use diamond cut tool to cut and repair wheel surface.PC wheel repair machine can directly optimize the curve and improve the machining quality of the wheel surface, without the need of another computer to make a special optimization, can save a lot of work time. PC wheel reapir machine is more easier to operate than CNC wheel repair machine and Do not need professional knowledge of the NC, Don't need to understand the complex programming process. It is convenient to opreate by touch screen and equipped with a wireless keyboard &mouse to meet the different operating habits.

PC Control Diamond Cutting Alloy Wheel Repair Equipment WRM2840 Feature:

1.Self developed professional wheel repair software.

2. Friendly man- machine interface, easy to learn and the people without professional training can learn the operation easily in one hour.

3. Detection, optimization and cutting can be finished in one system in a time.

4. The software can support the repair of curves by parts, make the surface of wheel perfect by cutting minimum cutting quantity.

5. The customer can establish their own database of different models of wheels and the saved data can be used in the cutting of same model.

6. Support the remote assistance, and any problems can contact with our company to start the after sale service.

7. Software support remote upgrade, enjoy life free upgrade to the latest version

8. Training video of the operation. | ITEMS | Specifications |

| Max. swig over bed (mm)(inch) | Φ770 (30') |

| Max. Size of alloy wheel (inch) | Φ720 (28') |

| Adjustable stroke of carrier in X direction | 100mm |

| Cross slide travel (mm) | 390 |

| Width of the rail (mm) | 300 |

| Length of the rail (mm) | 1300 |

| Size of the three-jaw chuck (inch) | 12' |

| Range of spindle speed (RPM) | 50~2000 |

| Spindle speed control | Automatic |

| Spindle bore (mm) | Φ82 |

| Taper of spindle bore | 1:20(Φ90) |

| Max. size of tool post | 25×25mm |

| Stations of tool carrier | 4 position |

| Min. setting unit of motor | (Z) long 0.001mm, (X) cross 0.001mm |

| Moving speed of post | (Z) long 8m/min, (X) cross 6m/min |

| Motor power | 7.5KW |

| Mchine base(cast iron base) | Whole |

| Machine size | (L×W×H) (mm) | 2140 ×1600×1860 |

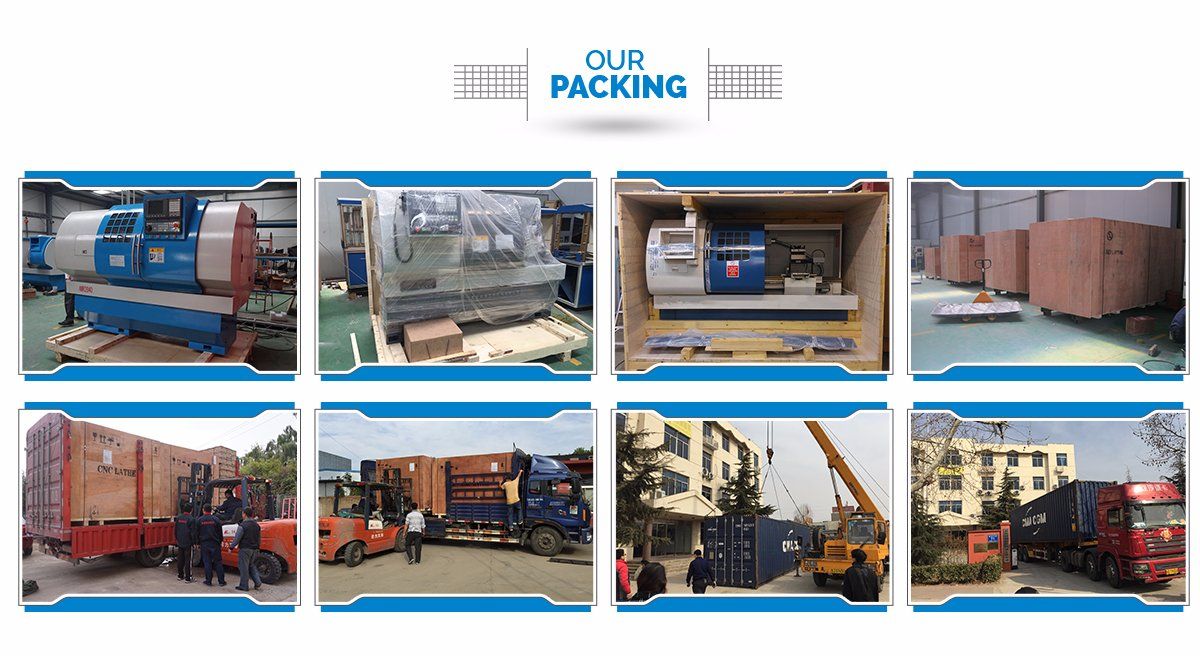

| Package size | 2300×1750×2100 |

| Net weight | 2200Kg |

Taian Crystal Machinery Co., Ltd., is a modern and high- tech company which is a professional manufacturer of CNC machining Center, CNC Lathe Machine, Wheel Lathe machine With 5, 000sqm workshops and offices, we have more than 15 years experiences in CNC machine research and production. Our machines have been exported more than 40 countries. We welcome all customers and friends to come to our company!

Our team have great experience on manufacturing and exporting. Our service department has experienced technicians that can offer you answers to your technical questions, and in many cases, solve your problem effectively over the phone.

We are dedicated to provide customers with the best, highly value added machines. We have earned a strong reputation in design and manufacturing of a wide variety of CNC machine tools. We continuously improve the performance level of our machines, strengthen our quality control system, and offer worldwide support services. Our dedication to the global marketplace will create a new era of CNC machine tools.

Furthermore, we are serious about quality, customer input, and reacting to market demands. Our fully equipped quality control department performs the final inspection of the machine and in process inspection of parts. Our quality control personnel are well trained to conduct rigorous inspections by using precision, sophisticated instruments. We deeply believe that quality is the life of our company and customer service is the power that drives our company forward. We are also looking for cooperation with professional dealers in the world. This would make us to create a new opportunity in certain area and offer top service quality as we have in China.