Product Specifications

| Prod Model: |

GYH-06AC |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Feature: |

High Efficiency |

| Warranty: |

12 Months |

| Duty Cycle: |

100% |

| Cooling: |

Water |

| Application: |

Heating, Forging, Melting, Hardening and etc |

| Work Condition: |

Continuously for 24hours |

| Customized: |

Customized |

| Principle: |

Regenerative Heat Exchanger |

| Structure Material: |

Metal Material |

| Heat Transfer Surface: |

Tubular Heat Exchanger |

Product Description

Steel Wire Brazing Ultrahigh Frequency Induction Heating Machine (GYH-06AC)Major Features:GYH super frequency heating equipment has such features as high frequency (the minimum heated welding diameter is φ 0.1mm), small size, light weight, low failure rate and conservation of energy (it can save the power by 70% as compared with glass-ceramic vacuum tube high frequency heating equipments). Furthermore, it can ensure the solid welding point which is pleasing and delicate in appearance, integral geometric configuration, perfect surface grain, complete crystal structure of internal metal part, limited annealing range and elimination of obvious weld knot. It is widely applied to the welding of couplers and inserts used in metal glass manufacturing as well as electric appliance and electronic industries, non-contact welding of internal parts of small-size relays, high-pressure refrigerating parts, headwear decorations, metal ornamental articles and art wares.

Major Scope of ApplicationA. Welding of big and small gears of hard alloy saw blade;

B. Welding and annealing of spectacle frame and fittings;

C. Welding of jewelleries, clock and watch;

D. Electric industry (tin and silver soldering of fine wire, various electronic elements);

H. Toy industry (tempering for wind spring and thin metal sheet)

G. Welding of cutting tools as well as tempering for paper cutter and shoe knife blade;

E. Electromechanical industry (silver and braze welding of fine metal joints as well as quench tempering for mini motor shaft);

F. Wire material industry (annealing of wire material and sheet band);

Parameter: | Model | GYH-06AC (Single phase) |

| input voltage | AC220V50HZ |

| input current | 23A |

| output power | 6000W |

| min power | 40W |

| fluctuating frequency | 1.5MHZ |

| product size | main:430 x280 x90mm |

| | part:230 x 100 x 115 mm |

| net weight | 12KG |

Delivery Time: within 10 workdays.

Shipping Term:By sea,By air,by express.

Extra accessories accept choose,

1>Chiller

2>Customer design Coil

3>Infrared Thermometer

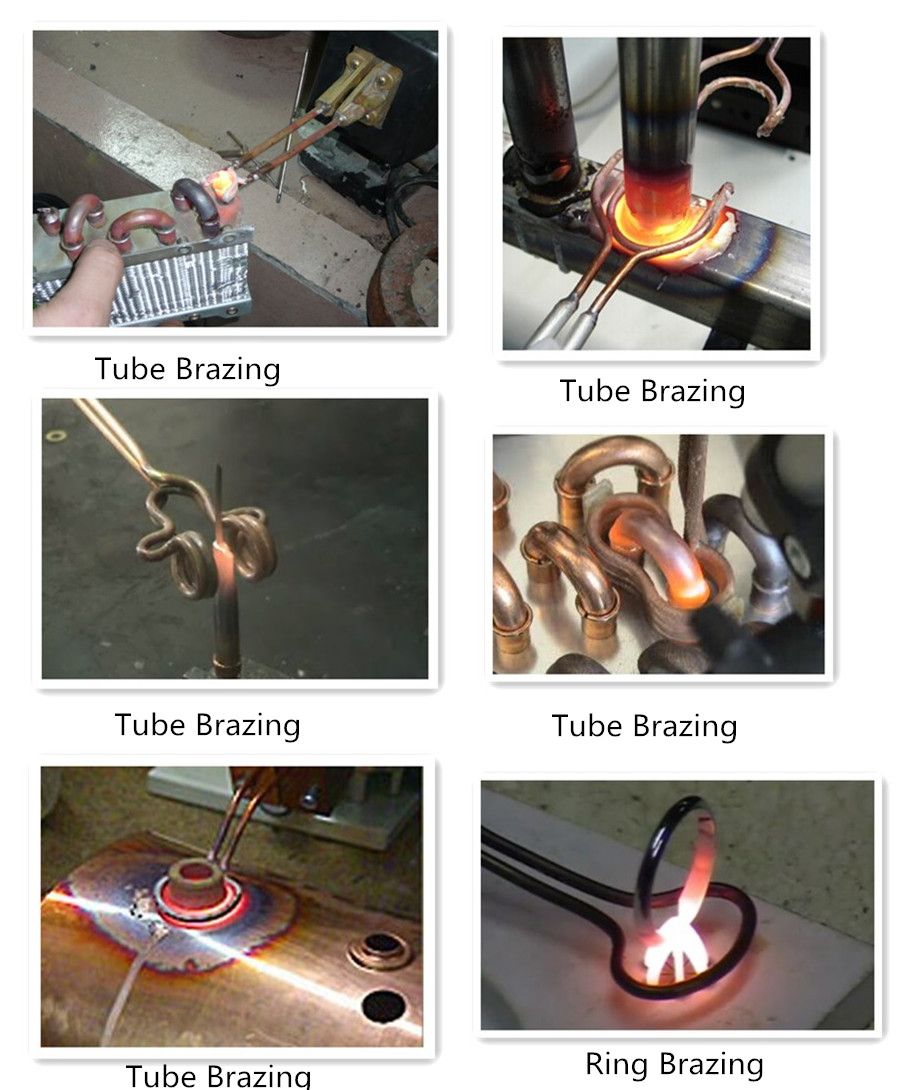

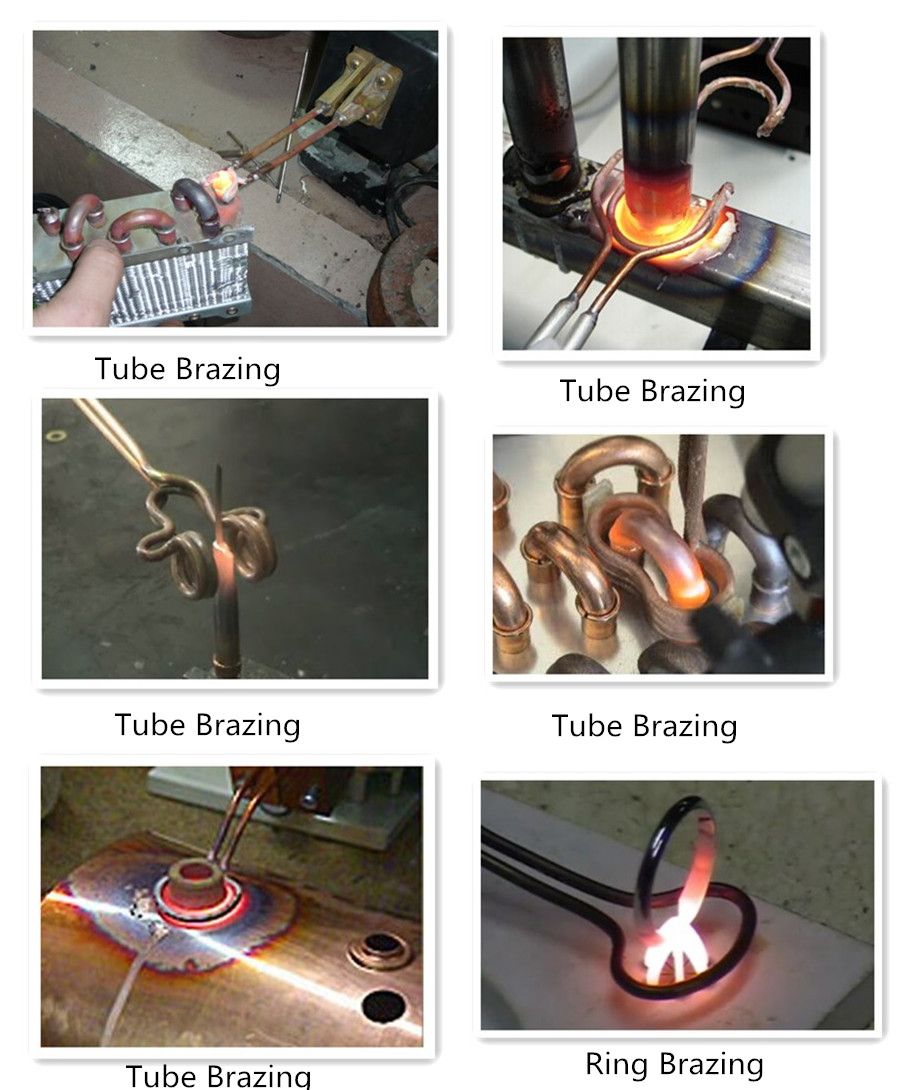

4>Back-up Electronic BoardsAbout service question:Q: Why choose GuangYuan Company?A: We are manufacture which had in this filed for nearly 20 years.No matter quality,price,service,delivery time,we all have large advantage.Q:How to choose suiteble machine?A:You can tell us your application,need forging,hardening,welding,melting or other,pass me workpiece material & size,Temperature requirement and heating time requirement.Then we will recommend fit machine for you reference.Q:How about the machine payment term&delivery time&Shipping term?A: Our company payment term accept T/T,Western Union,L/C and so on.Small machine delivery time is 3~7 workdays.Big machine delivery time 15~25 workdays.Shipping term accept EXW,FOB,CIF and so on.Q:How about the machine warranty?A:Our goods support one year warranty not by personal purpose,support technical service all life.During the warranty,if machine have problem need change spare parts,we can replace for you charge free.Work Principle& Application Photo

Founded in 1993, Dongguan Guangyuan Inverter Electronic Equipment Factory is a private high-tech factory. Our factory is located in Wanjiang District of Dongguan City in Zhujiang Delta, with convenient transportation near No. 107 national highway and Guangshen speedway.

We have established an R&D system. It is supported by advanced engineers and professional workers, who are especially engaged in researching and developing the machinery of middle or high frequency induction heating and high frequency inverter electrolysis and galvanization power supply. Since we owned strong technique development capability, our factory has been insisting on producing new product and new craftwork to assure our leading position on technique in this field.

Under the effort of several years, our factory has produced series of high quality products in various categories. We can also exclusively produce these products on your requirement to meet you need. Our middle or high frequency induction heating equipment is produced for special voltage condition of some countries. For instance, there is single-phase 110V, three-phase 220V induction heating equipment for America and Japan and three-phase 415V, 440V induction heating equipment for such southwestern Asia countries as Malay and Thailand.

Our factory has a wholesome distribution network. Our products are delivered to America, Europe and southwestern Asia areas. We also built up a lot of offices to provide prompt and quick service to our consumers.

At the beginning of our foundation, we advocated "work with honest and credit, service for ever". This slogan has deeply footed in the culture of our factory, becoming the soul of development and management. During the process of development, it is firmly believed that a wonderful after-sale service is the base stone for a company' S existing. Therefore, our factory takes the thought of "creating values for costumers" as the core of our managing strategies.

Chinese companies are facing the competition and challenge from the whole globe. Our factory will use advanced technology to provide better after-sale service and to find a proper position in the international market. We will hold the spirit of more professional, advanced and perseverant to pursue the wide application of our products in the market. We will also pursue the co-development and advancement with our suppliers and consumers relying on professional technology and good cooperation efforts.