Categories

Categories

| Price: | US $ 45000-50000Unit |

|---|---|

| Trade Terms: | FOB,CFR,CIF |

| Min Order: | 1Unit |

| Pay Type: | L/C,T/T,D/P,Money Gram |

| Prod Model: | QC12Y 6*3200mm |

|---|---|

| Markets: | North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Max Cutting Thickness(Mm): | 6 |

| Max Cutting Width(Mm): | 3200 |

| Travel Times(Min-1): | 12 |

| Stopper Adjust Range(Mm): | 20-500 |

| Power(Kn): | 7.5 |

| Overall Dimension(Mm): | 3840*1710*1620 |

Technical Files

MODEL:QC12Y 6*3200mm hydraulic guillotine swing beam shearing machine

Detailed photos of shearing machine:

Characteristic and feature

Assisting blade pedestal on worktable is convenient for micro adjustment.

Rolling material support ball is provided on worktable, convenient operation.

Using stepless adjusting structure to regulate the gap of blades, adapt to different thickness and materials.

The adoption of four-side edge shearing blade prolongs the service life of blade.

Regulating shearing process not only increases the production efficiency but also achieve the function of segment shearing.

It is provided with counting function for shearing to decrease the numerous artifical counting.

Hydraulic system

Advanced hydraulic integrated system is employed and the pipeline connection is minimized, to ensure the system reliability and safety.

It is consisted of some pressure feed cylinders installed at support board in front of machine frame. Pressure head press down against the pull force of stress spring, press plate tightly. After finishing cutting, the cylinders are reset by the pull force of stress spring. The pressure is bigger as thicker as the thickness of plate.

Back gauge

Back gauge is fixed on up-cut board, pendulum up and down as up-cut board. Adjust back gauge by 0.55Kw motor, reduce speed through gear, and drive by control rod. Brake down the button "+" (or"_"), can adjust gauge to front or back. When mechanic adjustment cannot get the necessity valve, turn hand-wheel to demanding value, the adjustment of back gauge is convenient and reliability. When the length of cutting plate is longer than the max distance of back gauge, remove the back gauge to the least place, lift up the board by the incline surface of support frame, and can cut any length of plate.

·Using servo-control technology

·Electrically operated rear bumper material and previous slide automatic positioning

·Entire Chinese operation contact surface,direct-viewing simple

·The multi-channel proced ure moves auto matically,procedure and procedure step link

·Keeps off the material to make conc essions automatically

·Programmable 10 jobs

·Stroke counter function

·Retract function

·Power off Memorization

·X-axis Software Limitation

·Inch/MM

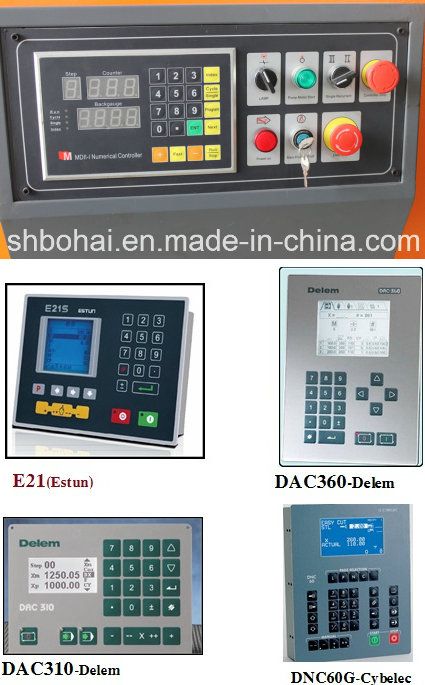

Controller for option

E21 Functions

· High-definition LCD screens

· Control ordinary motor and frequency converter

· Intelligent positioning

· Multiplex step programming, 40 program each step 25 workers

· Built-in time relay

· A key function to switch

· Unilateral positioning function

· Concession function

· Chinese/English & Metric/Imperial system transformation

DAC 360 Functions

· Panel mounting

· High brightness LCD screen

· The rear stopper control

· Yield control

· Shear angle control

· Shear gap control

· Shear stroke control

· Axes manually move

· Pressure control

DAC 310 Functions

· Using servo-control technology

· 275*48 picture element Gao Liang liquid crystal display monitor

· The electrically operated rear bumper material qutomatic positioning,make concessions automatically

· The multi-channel proced ure moves automatically,procedure and procedure step link

· The cutting counting,cuts the regulation to define that the power failure remembered,male/British system transformation

DNC 60G Functions

· 5.5 inch high contrast LCD LCD monochrome display

· High quality large waterproof antifouling touch type keyboard, long life

· Digital programmable display and post-processing, direct programming point of view

· Programming is simple and efficient, the revision process all programming focused on a page (programming) completed within

· Automatic calculation of expansion length, large arc, stress, deflection compensation, positioning, clamping point

· Quick positioning angle correction, correction

· Using SMD, ASIC and multi processor technology, is a model of advanced manufacturing technology of highly integrated design; the structure is compact, high reliability

· Static memory with memory function

· Can choose the embedded installation and cantilever installation (special housing options)

As the parent company of Shanghai Wanjiao Machine Tools Co.,Ltd and Maanshan Huayu Machine Tools Co., ltd,BOHAI owns one of the the most contemporary production plants in the industry in China.

The main products of the company are guillotine shears,hydraulic swing beam guillotine shears,hydraulic plate bending machine and other complete set of forging equipment,various type of toolings and cutters,spare parts for machine tools etc.Three different ISO certified factories producing different product families employ 300 employees.

In order to offer customer solutions and further develop patents, the BOHAI R&D center opened in 2000. Now, there are fifteen engineers serve for the R & D center.

Designed and engineered with modern technology, Bohai products are equipped with high quality and proven readily available components.

Established in 1989, Bohai has vast experience in building and supplying high quality products. With over 60,000 machines delivered worldwide, Bohai has earned a reputation as a supplier of innovative "value oriented" solutions.

We promise solemnly:BoHai honor,is our each person's honor,only hard work,in order ro maintain the honor,enterprises can develop continuously,continue to grow together with customers,will be rooted in the integration of resources of the world back to the world,is the ultimate goal of BoHai enterprises.

Our company will grasp the opportunity,gather large number of talented people,increase competitive power in the science and technology of products,accelerate enterprise development and provide higher quality products and service for our new and old customers.