Puffed Rice Cracker Making Machine

| Price: |

Negotiable/Piece |

| Trade Terms: |

FOB,others |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T |

Product Specifications

| Prod Model: |

SLG65/SLG70/SLG85 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Machine Material: |

Stainless Steel |

| Motor: |

Chinese or Siemens or ABB |

| Capactiy: |

100-600kg/H |

| Guarantee: |

12months |

| Low Electric Cost: |

High Profit |

Product Description

Thin and long Automatic Nutritional Rice extrudering machine

1.Production Description of Nutritional Rice extrudering machine :

Artificial rice is mainly produced by single-screw extruder. It has the abundant nutrition and the similar shape to the rice. If you want to get the clean, crystal and high-ranking rice, you must use a polishing machine.

It has the following features: high degree of automation, saving energy. It takes the rice, millet, black rice, buckwheat and all kinds of corns and cereals as raw material and makes the vitamin, protein and mineral composition mixed, extruded, then it can become the rice appearance again.

This process is easy and convenient and has the same edible method as the natural rice.

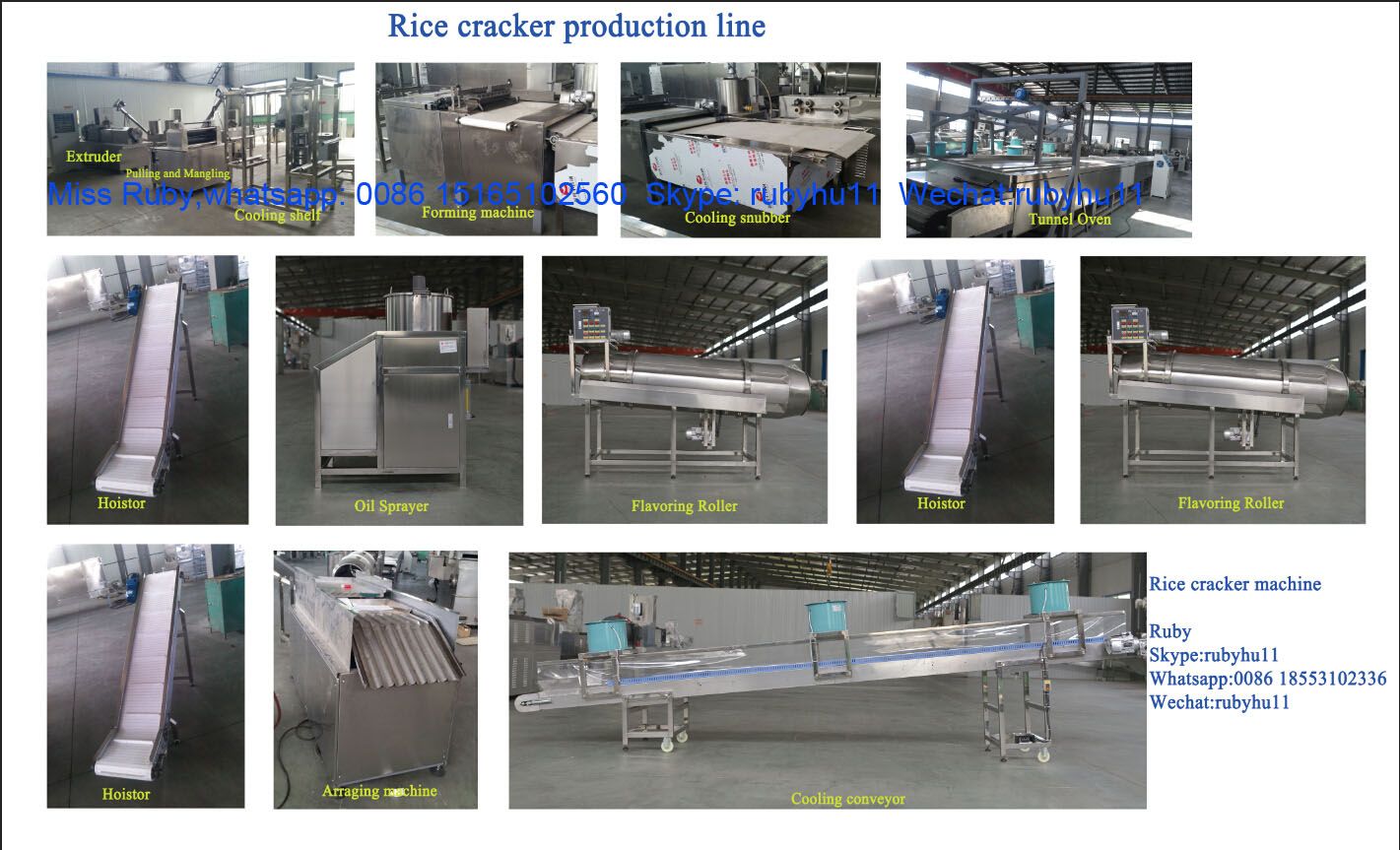

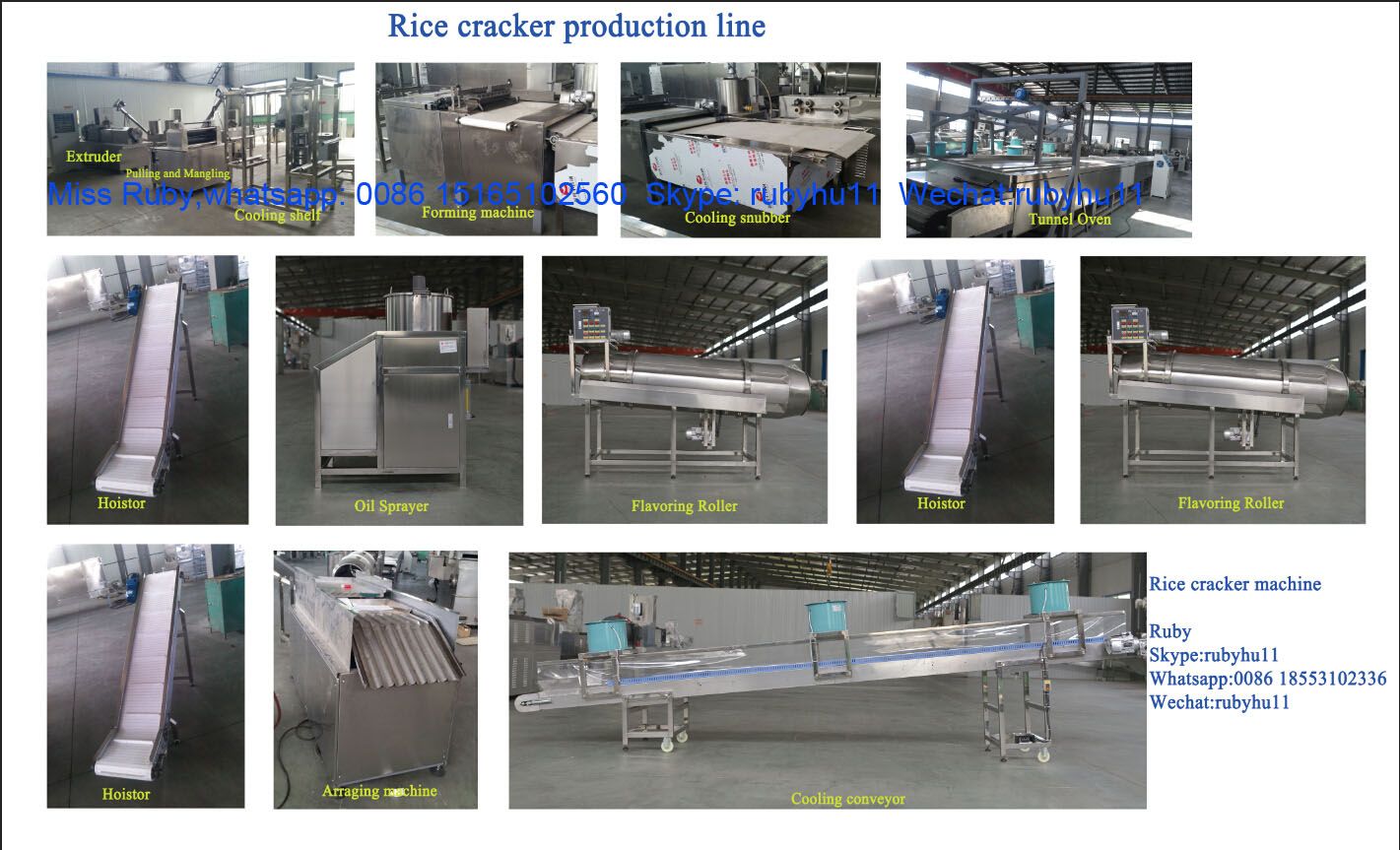

2.Equipments of Nutritional Rice extrudering machine :

Raw material---Mixer---Screw Conveyor---Single-screw Extruder---Air Conveyor---Five-layer Oven---Air Conveyor---Polishing machine

3.Technological Process of Nutritional Rice extrudering machine:

Raw material---Mixing---Screw Conveying---Extruding---Air Conveying---baking

4. Technical Parameters of Nutritional Rice extrudering machine:

|

DLG100 Artificial Rice Equipment |

SLG70 Artificial Rice Equipment |

Installed capacity |

95KVA |

105KVA |

Output |

100-120kg/h |

200-240kg/h |

Dimension |

15×2×4m |

18×2×4m |

5. Sample Photos of of Nutritional rice:

6. Nutritional Rice crispy extrudering machine :

The machine has excellent performance and final product has high quality. Sincerely welcome you come to our factory inspect the machinery. Stainless steel, this line is with reasonable design and with high automation; The screws are made by alloy steel, with building block system structure and self-cleaning function.

8.Company Information:

Saibainuo is a leading manufacturer of high quality twin screw and single screw extruders for food industries.

We have almost ten years'experience of working with our customers providing specialist designs and practical

solutions for a wide range of process needs. Textured soya protein machine

We have been supplying the most efficient equipment available to snacks food manufactures around the world.

A comprehensive range from mixers to extruders,ovens ,flavors offers various tastes and easy to operate designs which lead the industry.

Factory standing area:30000 square meters Workshop standing area:20000 square meters.

Office area:4 floor with 600 square meters.

We keep very close cooperation and exchanges with many worldrenowned manufacturers and

domestic research institutions. In addition, with our quick access to information, timely delivery,

reliable quality and perfect service, our products have been exported to USA, Europe, Africa and

near countries such as Japan,India and Southeast Asia, recognized by broad masses of customers.

9.our service:

After-sale service:

1.Free Training:

Teach your staff or technicians how to operate and maintain the machine.

2.Engineers service overseas:

When the machines reach your factory,we will dispatch our skilled engineer to do installation for you on time.The installation time will take 7 days.

3.24 hours

Any problem using the device,within 24 hours we will provide guidance to sustomers via email,telephone or video.

4.Warranty

One year full service warranty and lifetime maintenance.

5.Other supporting

New production techniques and formulas.

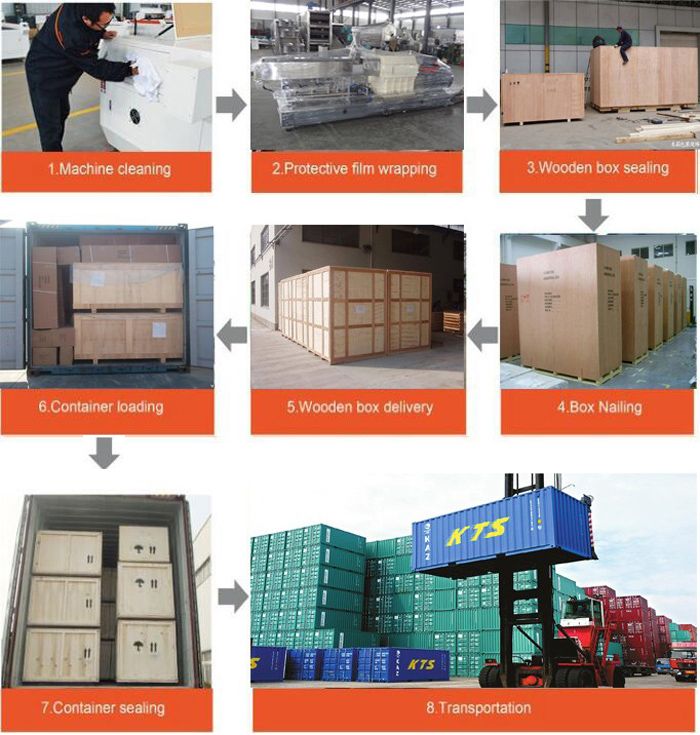

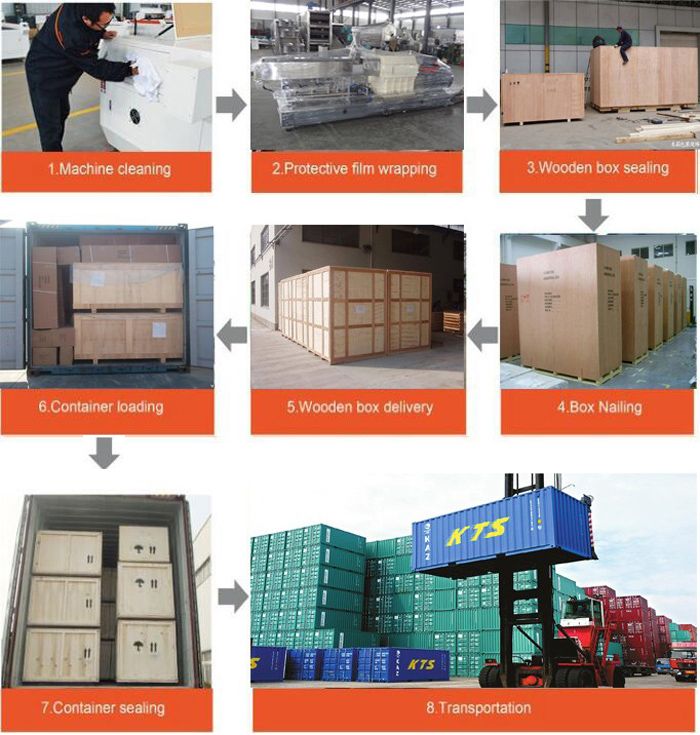

packaging and shipment:

1.Firstly packed with plastic bags.

2. secondly wooden packing cases.

3.finally putting the wooden cases into the container if delievered by sea

BV Inspection and CE Certificate:

Our factory has passed BV Inspection and all machine has CE Certificate.And before shipment,we also can do SGS inspection.Promise quality.

Machine list in saibainuo company.

No. |

Production line |

1 |

Pet food processing line for dog,cat ,fish |

2 |

Pet chews/treats processing line |

3 |

Nutritional artificial rice processing line |

4 |

Corn flakes processing line |

5 |

Breakfast cereals processing line |

6 |

Core-filled snack processing line |

7 |

Texture soy/vegetable protein food processing line |

8 |

Pellet chips processing line |

9 |

Pasta/Macaroni processing line |

10 |

Bread crumbs processing line |

11 |

Baby food processing line |

12 |

Modifield starch processing line |

13 |

Cheese curls extruder |

14 |

Fresh potato chips processing line |

15 |

Examination Twin-screw extruder |

Established in 2004, Jinan Saibainuo Technology Development Co., Ltd. is a professional manufacturer of extrusion snack, pellet machinery, pet foodstuff, TSP/TVP and packaging machinery.

The company has congregated an expert team, which has been working in this field for over 10 years. We can keep product design in the same level with internationally advanced technology consistently. Moreover, we have high diathesis staff and excellent processing equipment, and quality control runs through the whole production process from parts stock to the beginning of production. We can guarantee customers superior quality machines up to design requirements and perfect working state. Our technicians can also provide all kinds of relevant technology to make the food production clean, healthy and safe.

Saibainuo Company engages in the technical research of extrusion foodstuff, in order to let our clients have superior foodstuffs to sell in the market. We can improve client's equipment and provide related training on new advanced technique. We can also make special designs for special products and materials according to clients' special requirements.

At present, Our Company locks in 70% market share in Oversea, and our products have been selling well to Germany, Australia, Ukraine, Malaysia, Indonesia, Syria, Philippine, Thailand, Romania, South Amercia, Middleeast, Africa and other countries or regions.

Presently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more details.