Product Specifications

| Prod Model: |

TSE-65 |

| Model: |

Tse-65b |

| Motor Power: |

75kw |

| Diammter: |

62.4mm |

| L/D: |

32-64 |

| Screw Speed: |

600r/Min |

| Capacity: |

250-3500kg/H |

| Color: |

Any Color as Required |

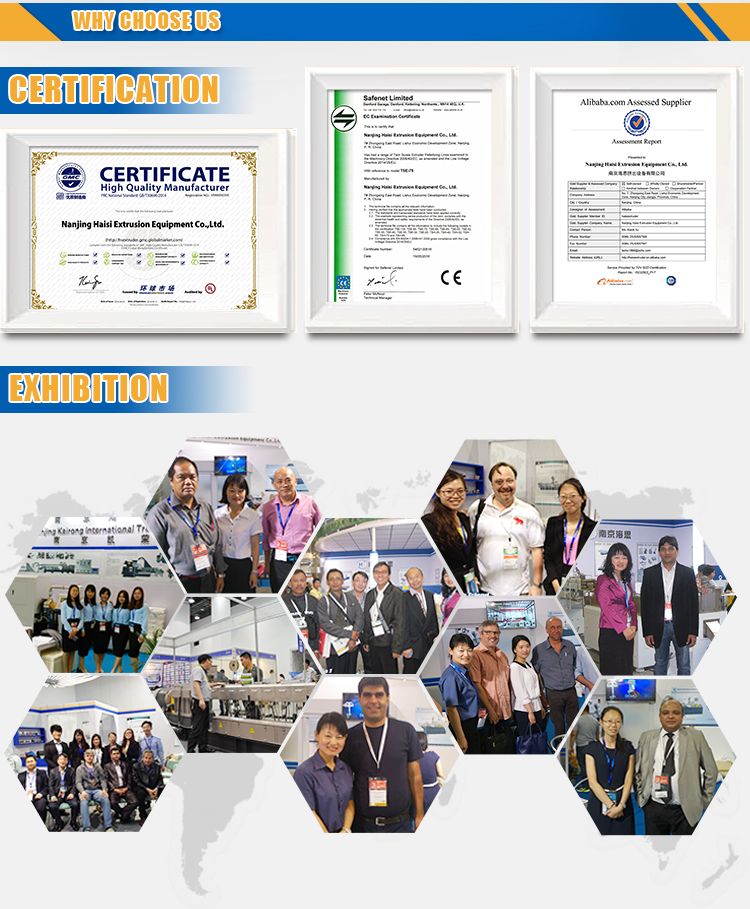

| Certification: |

Ce ISO9001 TUV SGS |

| Warranty: |

1 Year |

| Product Type: |

Granulating Extruder |

| Feeding Mode: |

Multiple Feed |

| Assembly Structure: |

Separate Type Extruder |

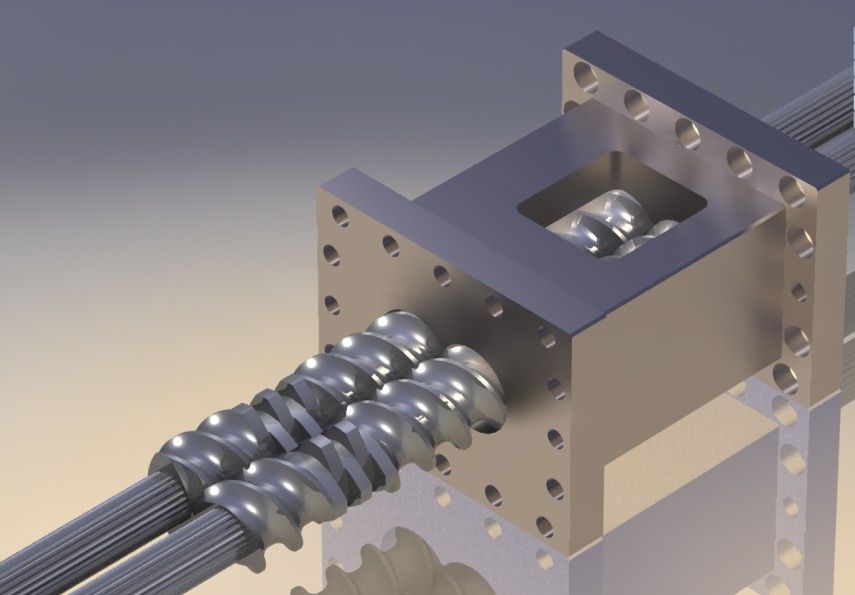

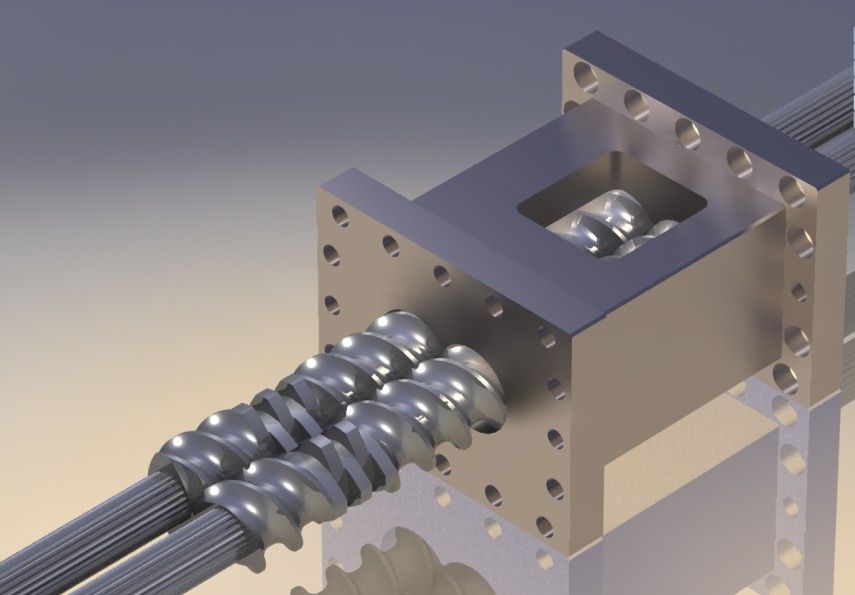

| Screw: |

Twin-Screw |

| Engagement System: |

Full Intermeshing |

| Screw Channel Structure: |

Deep Screw |

| Exhaust: |

Exhaust |

| Computerized: |

Non-Computerized |

| Type: |

Plastic Extruder |

| Plastic Processed: |

PE PP PC EVA ABS PA Polyethylene |

| Automation: |

Semi Automatic |

Product Description

PA PS extrusion machine price for granulating

Representative Material:

Representative Material:*Mixing nature-changing:

PE, PP, PS+SBS, PA+EPDM, PP+NBR, EVA+silicon rubber;

PE, PA, PC, CEP+ABS(alloy), PBT+PET, PP+PE

Filling nature-changing:

PE, PP, EVA, Calcium carbonate, talcum powder, titanic powder;

ABS, PC, PS, Aluminum hydroxide, magnesium hydroxide, antimony oxide;

PP, PA, ABS+ferrous powder, sulphuric powder, ceramic powder

Functional machine pellets:

PP, PA, ABS, PBT+anti-burning agent and other auxiliary agents: Combustion-supporting machine pellets;

PS+starch: De-composing machine pellets, PE+fog-preventing dipper, stabilizer: Dual-prevention machine pellets; PE, EVA, ABS+carbon black: Black machine pellets

Colored machine pellets:

PE, PP, ABS, AS, PA, EVA, PET+pigment and auxiliary

Intensified glass fibres and carboon fibres:

PP, PBT, ABS, AS, PA, PC, POM, PPS, PET+long fires, small fibres, crystals

Various cables:

HDPE, LDPE, LLDPE, MDPE, EVA, PVC, PP, Lnsulating cables;

PE peroxide silicon

Characteristics*PP/PA/PC Plastic Granulator Of Plastic Extrusion Machine use innovated design of heater tightened style, it insures high efficiency of heat transfer and high longevity of heater.

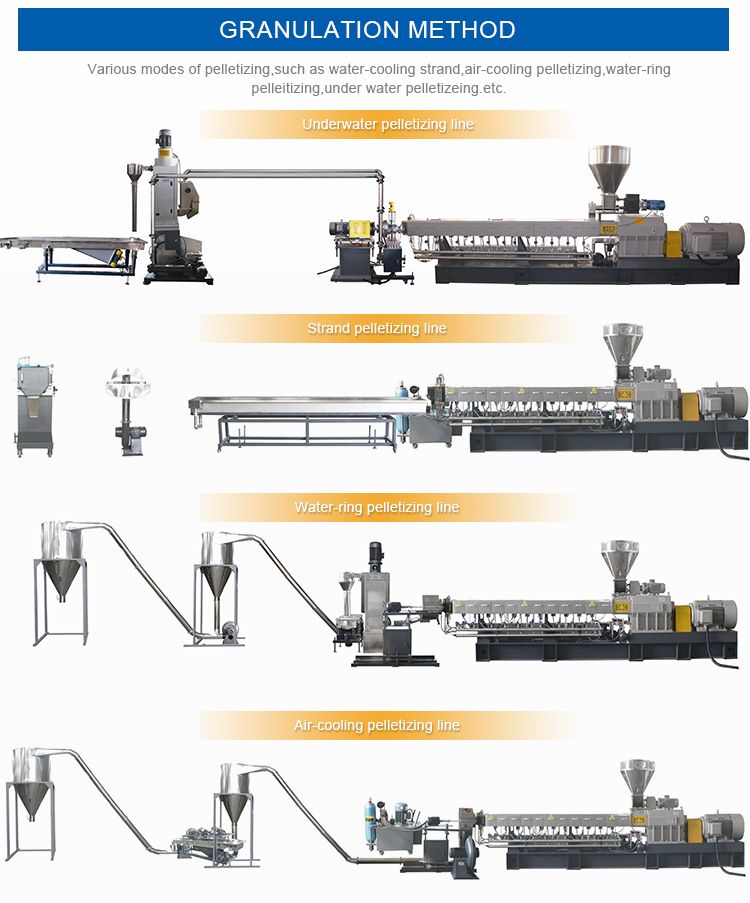

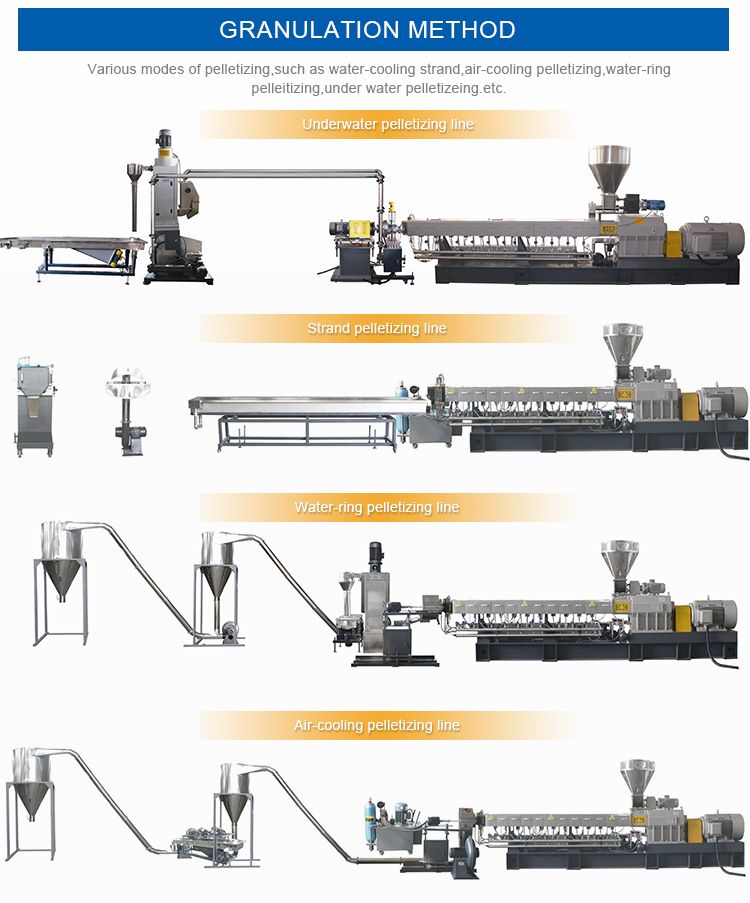

*PP/PA/PC Plastic Granulator Of Plastic Extrusion Machine has Various modes of pelletizing, such as water-cooling strand, air-cooling pelletizing, water-ring pelletizing, under water pelletizing etc.

*The screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2 by special heat-treatment, which is possessed with high corrosion-resistant and high functions

*The screw configuration, barrel setup, L/D or mode of feeding and venting, screen changing, way of granulating, and the control mode can be optimally adjusted according to different materials properties and requirements in consideration of the versatility in each general applications.

Granulation Method

Granulation Method About Our Company

About Our Company

5. Haisi Service Stystem

Before-sale:

*Introduce products in detail

*Recommend suitable solution

*Offer test

During Manufacturing:

*Provide layout and engineering conditions

*Offer screw plan and related documents

*Inform the project processing status

*Insure the product designed in accordance with technical document

After-sale:

*Provide installation, commissioning and training

*Offer spare parts

*Provide necessary techinical support and update infoamation

If you have any questions, please don't hesitate to contact me or send an inquiry to me!

| Mode | Diameter | L/D | Screw Speed | Screw Torque | Motor Power | Capacity | Weight |

| TSE-20 | 22mm | 32-44 | 600r/min | 43N.m | 5.5kw | 0.5-10kg/h | 1000kg |

| TSE-30A | 31mm | 32-48 | 500r/min | 105N.m | 11kw | 5-30kg/h | 1500kg |

| TSE-30B | 31mm | 600r/min | 119N.m | 15kw | 5-40kg/h | 1500kg |

| TSE-35A/B | 35.6mm | 32-52 | 600r/min | 119N.m | 15-22kw | 20-60kg/h |

|

| TSE-40A | 41mm | 32-64 | 400r/min | 263N.m | 22kw | 65-110kg/h | 3000kg |

| TSE-40B | 41mm | 32-52 | 600r/min | 239N.m | 30kw | 90-150kg/h | 3000kg |

| TSE-50A/B | 50.5mm | 32-52 | 500r/min | 430N.m | 45-55kw | 135-270kg/h | 3000kg |

| TSE-65A | 62.4mm | 32-52 | 400r/min | 895N.m | 75kw | 180-250kg/h | 4000kg |

| TSE-65A | 62.4mm | 32-52 | 500r/min | 716N.m | 75kw | 180-270kg/h | 4000kg |

| TSE-65B | 62.4mm | 32-64 | 600r/min | 716N.m | 90kw | 200-300kg/h | 4000kg |

| TSE-65C | 62.4mm | 32-64 | 600r/min | 875N.m | 110kw | 220-350kg/h | 4000kg |

| TSE-75A | 71mm | 32-56 | 400r/min | 1074N.m | 90kw | 250-350kg/h | 4000kg |

| TSE-75A | 71mm | 500r/min | 1050N.m | 110kw | 300-420kg/h | 4000kg |

| TSE-75B | 71mm | 32-64 | 600r/min | 1050N.m | 132kw | 350-550kg/h | 4000kg |

| TSE-75C | 62.4mm | 32-64 | 600r/min | 1273N.m | 160kw | 400-600kg/h | 4000kg |

| TSE-75D | 71mm | 32-64 | 600r/min | 1990N.m | 200-250kw | 500-1000kg/h | 4000kg |

| TSE-95A | 93mm | 32-64 | 500r/min | 2387N.m | 250kw | 600-1000kg/h | 4000kg |

| TSE-95B | 93mm | 32-64 | 600r/min | 2506N.m | 315kw | 800-1200kg/h | 4000kg |

| TSE-135A | 93mm | 32-64 | 500r/min | 7162N.m | 750kw | 1500-2250kg/h | 4000kg |

FAQ 1. Q:Are you A factory or A trading company?

A:Both

2. Q: What makes you different for other suppliers?

A: 1)firstly,our factory is very professional in twin screw extruder for many years. and our machine's quality is best in our field and our price is also competitive from other suppliers.

2)second, our service is very excellent. and our engineers is avaliable to service the machine overseas and if you have any questions you can contact us at any time, we will reply you in 24hours.

3.Q:What is the payment?

A: 1) T/T payment; 2) LC;

4.Where is your factory located? How can I visit there?

A: Our factory is located in Nanjing, Jiangsu Province, China,

1) You can fly to Nanjing Airport directly. We will pick you up on Nanjing Lukou International airport;

2) You can fly to Shanghai Pudong International Airport then come to Nanjing by High-speed railway, then we will pick you up in the railway station.

All our clients, from domestic or abroad, are warmly welcome to visit us!

welcome to contact us