Categories

Categories

| Price: | Negotiable/Piece |

|---|---|

| Min Order: | 12/Piece |

| Pay Type: | L/C,T/T,Western Union,Paypal,Money Gram |

| Prod Model: | B4010 |

|---|---|

| Product Name: | New Optical Frames |

| Certificated: | Ce FDA |

| Service: | OEM ODM |

| Minimum Order: | 12PC |

| Lead Time: | 7 Days |

| Lens: | Demo Clear Lens |

| Color: | Red, Brown, Blue |

| Material: | Environmental Acetate |

| Sample: | Sample Available |

| Frame Material: | Acetate |

| Nose Support: | Non-Integrated |

| Usage: | For Optical |

| Frame Color: | Black |

| Style: | Fashion |

| Suitable For: | Woman |

| Glasses Style: | Full frame |

| Frame Shape: | Oval |

| Metallic Materials: | Brn/Black |

| Suitable For Face: | All Face |

| Material | Frame:High quality Acetate |

| Lense:Clear lense | |

| Color | 3 COLOR |

| MOQ | ODM:1 pc |

| OEM:300 pcs | |

| Payment Term | 30% deposit before production, 70% balance before the shippment. |

| Delivery Time | ODM:5 days |

| OEM:75-90 days after receving the deposit for order | |

| Brand | Paul Eyewear;Custom logo is available |

| Port | Shanghai |

| Sample charge | Around 5-10USD/PC |

| Sample Lead Time | READY MADE:2-7DAYS, OEM PRODUCTION:90DAYS |

| Packing | 1pcs/opp bag, 12 pcs/inner box, 300 pcs/carton.Carton Size:81*23*35cm |

| Standard | CE FDA UL BV |

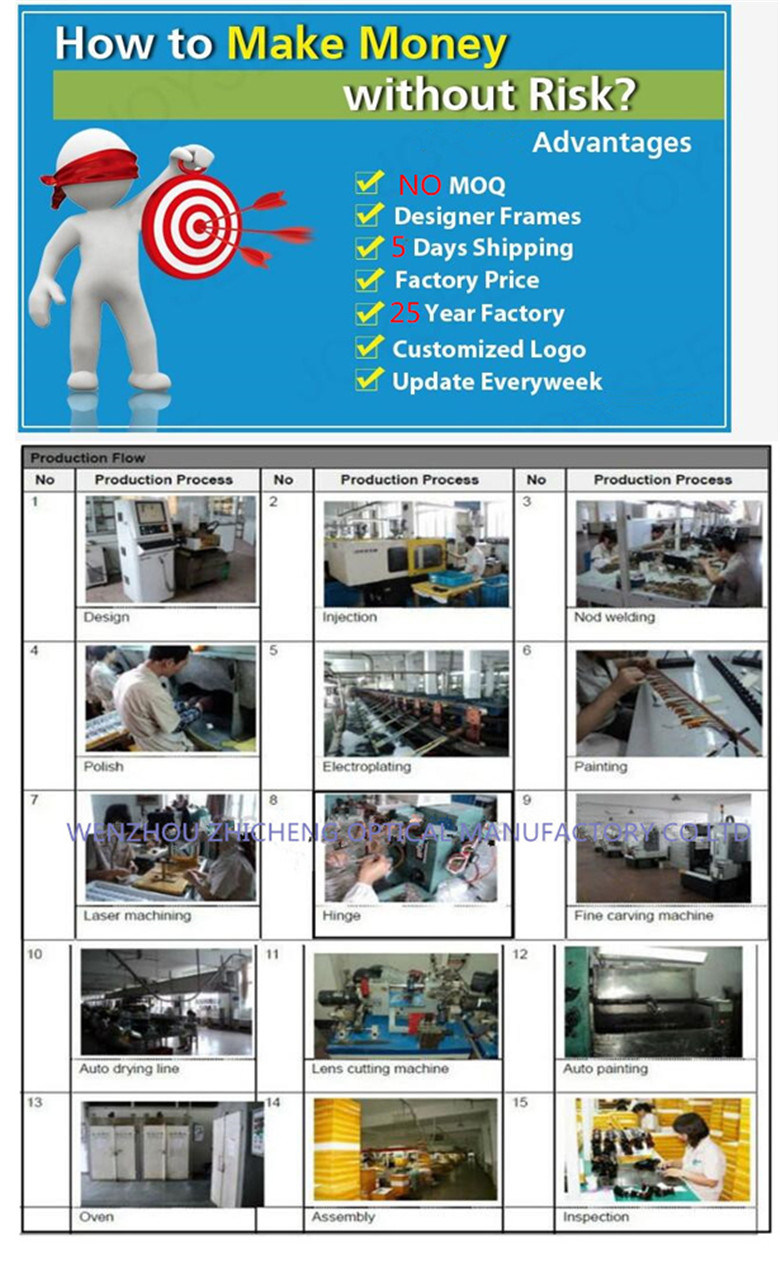

| WHY CHOOSE US |

| 25 years manufacture and design experience |

| 35-45 new models every month |

| Minimum order ONLY 1PC EACH COLOR |

| 481 Ready made optical frames and sunglass |

| CE FDA UL, 1 year Products warranty. |

OUR ADANGATGES |

| 1) Factory direct selling,481 models ready made |

| 2) Eyeglass with Spring Hinge, Diamonds,Enamel,Super thin, different shapes |

| 3) 102150 Pieces ready in warehouse. |

| 4) No minimum order, You don't have stock and money pressure |

| 5) 5 days fast delivery, Door To Door Service |

| We have favorable shipping charges with TNT ,DHL,Fedex,UPS,etc |

| Can do customs clearance for you if you worry about taxes |

| 6) 35-45 New models each month,you can get the new model at first time like the big company |

| 7) Quality warranty:1year |

HANDMADE ACETATE SUNGLASSES&EYEGLASSES

ACETATE:ALL RAEN sunglasses and eyeglasses are produced from sheets of high level acetate,the highest-grade cellulose acetate available.Acetate is a high quality plastic originating from the renewable resources of wood pulp and natural cotton fibers.It has become the standard raw material used to build high fashion and long lasting glasses.Most high-end sunglasses and eyeglass manufacturers exclusively use the known brand acetate for their products,and we are no exception.Acetate retains itscolor brightness impeccably over time because its hue is embedded in the material rather than sprayed on which also prevents and color peeling.Unique aging stabilizers in acetate also prevent fading,yellowing or other discoloration from UV light or skin contact.

STEP ONE:DESIGN

Our designers create modern takes on vintage inspired frames.Finding our inspiration in MidCentury design,we look to everything from furniture and architecture to boats and automobiles for influence for our collection.Working with classic shapes allows us to produce timeless pieces.

STEP TWO:CUTTING

We generate custom acetate combinations each season that are unique to our collection.Select styles each season are outfitted with one-of-a-kind acetate combinations are applied to thin flat sheets of acetate in preparation of cutting.A computer-controlled router then cuts each component of the frame directly from Auto CAD renderings created by our RAEN design staff.

STEP THREE:MILLING&POLISHING

Each individual frame component is outfitted with its hardware by a highly trained technician, The frames are then "formed"according to their predetermined templates.After"forming"the senior technician checks each frame with a micrometer at tolerances of one-hundredth of an inch.Our frames then begin the polishing process by tumbling in a barrel of wood chips an small stones for about 12 hours.With the intricate design of our frames and the unique details of each style,each frame must be hand finished by one of our technicians.Each frame is hand finished/buffed using a polishing wheel, similar to the way jewelry is polished ,to ensure longer lasting luster.

STEP FOUR:FINAL ASSEMBLY

During final assembly technicians fasten arms to each frame with spring or five-barrel hinges and tiny screws,hinges function as the joint between the frame temple and each arm to maintain an effortless an secure bend arms, Because screws are made to loosen, the RAEN technicians use self-sinking/locking screws to ensure that are kept secure.

| 1 | Could i put my own logo on it? |

| Sure,customers'logo can be made by laser,engraved,embossed,transter,printing etc. | |

| 2 | Should I pay extra for logo printing? |

| According to the actual situation.Customer logo available | |

| 3 | How about the quality? |

| Have acquired the CE&FDA Certification. 100% QC in produce process and before the goods being packed up.Accept the 3rd part to do inspection. | |

| 4 | Could I buy 1pc sample first and small order? |

| Of course,we support sample order and small order,especially foe new customers under certain condition. | |

| 5 | How much for 1pc sample? |

| Some cheap ones can be free for one piece of each style but need to check the actual stock. Some expensive ones like acetate and stainless steel,wooden, then we will quote you USD 10/PCs for the sample order. | |

| 6 | If I have my thoughts,do you have person to design according my concept? |

| Certainly,our design team is willing to do it for you. | |

| 7 | How long to make a sample? |

| 5-15days depending on the samples' complexity. | |

| 8 | Is the sample fee refundable or not? |

| Sure,refundable once the order is confirmed. | |