Product Specifications

| Prod Model: |

JJ-GP80X |

| Input Power: |

80kw |

| Input Voltage: |

Three Phase 380V, 50-60Hz |

| Oscillation Frequency: |

30-100kHz |

| Net Weight: |

49.4/50kg |

| Application: |

Quenching, Annealing, Welding, Melting |

| Model: |

Jj-Gp80X |

| Name: |

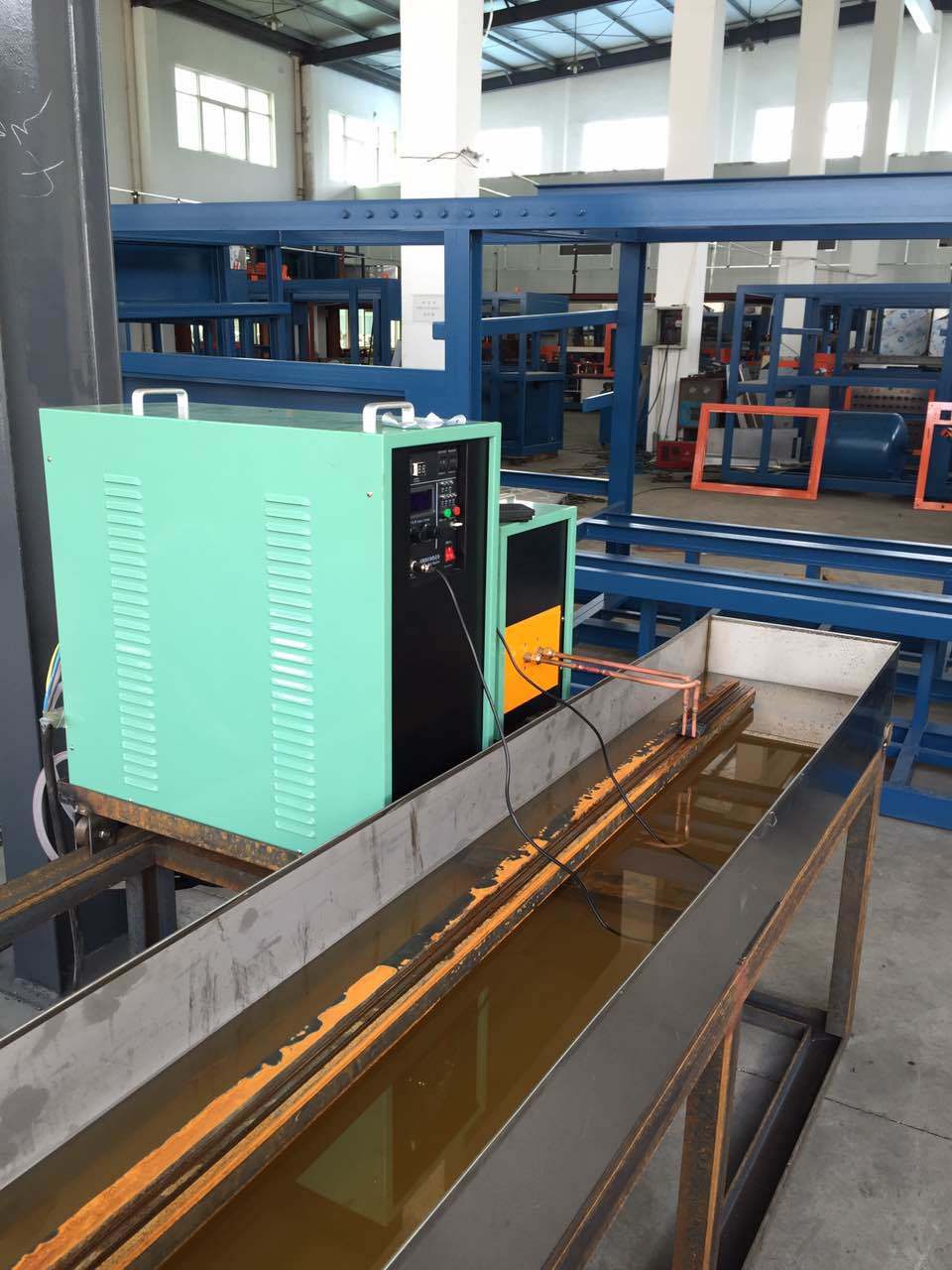

Solid State High Frequency Induction Heating Equi |

| Color: |

Green and Black |

| Usage: |

Metal Heat Treatment |

| HS: |

8514400090 |

Product Description

| Model | JJ-GP80X |

| Input power desire | 3 phase 380V,50/60HZ |

| Oscillate power max | 80KW |

| Actual power | 70KW |

| Max input current | 130A |

| Oscillate frequency | 30-100KHZ |

| cooling water desire | 0.3Mpa≥6L/Min |

| Duty cycle | 100% 40ºC |

| Dimensions(L*W*H) | 63.5x31x62.5CM |

| Net weight | 49.4/50KG |

| Cable length | 2-6(Meters) |

high frequency induction heating machine Features:

1.power saving: Than the electron tube power saving 30%, than the thyristor intermediate frequency power 15-20%

2,the function stabilized:protection is all in readiness,has no worries about one's family.

3.heat speed quickly:the nothing oxide layer,deformation are minor.

4.it is convenient,easy to operate to install.

5.the inductor keeps apart from the transformer,safe.

6,environmental protection:do not contaminate.noise and dust.

7.it is extensive to use:can heat all kinds of workpiece.

8.fault rate is low:the component is screened strictly,measure and guarantee the apparatus works steadily.

9.Complete protection:it has fault alarm(lack water,lack phase,over current,over voltage)so it can avoid the machine to work under fault.

10.As the same principle of induction cooker,hand touch heating circle,not charged,don't burn.It only has 380v,no high voltage risk.

11.Load rate is high,above 80%.

12.Widely used: can heat treatment all kind of metal.such as quenching,annealing,welding,hot forging,melting,shrink fit,heat integration,exhaust pipe bluing etc.

13.Transformer primary coil use multi-stand conductor ,avoid the traditional copper pipe no water,easy to jam,burn out.

Our panel use new digital LCD display have advantage as follows:

1.it has manual mode

2.it has automatic mode

3.it has clock

4.it has timing function(with millisecond)

5.it has count function

6.it is more convenient to adjust and use.

7.it can be accurate to microseconds

The induction coil design and manufacture

1.The shape of the induction coil, should according to the heating surface shape workpiece,Production principle should

make induction part of brass and workpiece heating surface parallel or isometric and adjacent interturn current direction

should be consistent

2.The clearance between the induction coil and small artifacts should be controlled in 1-3 mm is advisable

3.material selects and uses the diameter 6 the above(wall thickness red copper tubes with 1 mm best)

the diameter>10mms brass selects and uses method of brass best

4.Connected to the machine of electric contact surface should be clean the oxide layer

5.Make full use of the approach of the current effect and gap effect, when it is necessary to add magnetizer

6. After induction coil is made, with the machine match, a frequency within the prescribed scope

Heat treatment for various hardware and tools, such as plier, wrench, hammer, ax,screwing tools and shear

Heat treatment for various automobile and motorcycle fittings, such as crankshaft,connecting rod, piston pin, chain wheel, aluminum wheel, valve, rock arm shaft,semi drive shaft, small shaft and fork.

Heat treatment for various electric tools, such as gear and axes.

Heat treatment for machine tools,such as lathe deck and guide rail.

Hardening for various hardware metal parts and machined parts, such as shaft,gear chain wheel, cam,chuck and clamp etc.

Heating for hardware molds, such as small-size mold, mold accessory and inner hole of mold.

Annealing of various stainless steel products, such as stainless steel basin,annealed and extruded can, annealed folded edge, annealed sink, stainless steel tube, tableware and cup.

Forging of various other metal work pieces, such as round steel, sheet/plate, pipe and others.

Welding of various meatal products,such as drill bits,cutter teeth,accessories,tool bit etc.

Company profile:

YongKand JianJin Electronics Co.,Ltd is a China based company with 12 years experience in special induction heating equipment region. Our R& D team has developed different induction machines for varied applications, and our machines have been successfully installed and commissioned all world wide.

We are a leading manufacturer of reliable, high quality induction heating equipments, that ensures an excellent payback on your investment. Besides, JianJin Electronics Co.,Ltd can provide specific application oriented equipment to meet individual needs of our customers and assist you with automation of the machines offered.If you have any interest in our products, pls do not hesitate any more, our staff will give you the best service at the first time.

FAQ:

1.which countries your products are exported to ?

Our products are sold all over the world and with related certifications.

2.How to install your machine?

We have paper installation instructions and videos ,we will teach till you learn it.

3.How about the warranty?

All our products have one year quality warranty,during the warranty time,the spare parts replacement is free,and we

provide life long time technical support and other assistance.

4.Which export port you use?

Any China port,commonly we will use Ningbo Shanghai port,can appoint as you like.

5.If I have paid but can not receive the goods,how should I do?

Alibaba international website is a famous trade platform and has been mature those years,every merchant on it has

paid large integrity fund,and we have China business licenses which can be checked on China official website or we

can show it to you,so that situation will never appear, please be assured.

6. How about the payment ways and delivery time?

30% deposit,70% before sending the goods(we will shoot total delivering process for customer's confirmation)and the

related papers.You can pay by T/T,L/C,western union or other ways.The small machinedelivery date is within 7 days,

the bigger one takes about 15days,we will delivery goods on time.

7.What is your nature of your company,dealer or factory?

We are manufacturer, warmly welcome to visit our factory.

Contact details:

cell:86-18067607118

wechat:luckywcx2016

Yongkang Jianjin electronic equipment factory was established in 2006, We are specialized in the researching and manufacturing of new type induction heating equipment. It include high frequency(20kw to 80kw), superaudio frequency(40kw to 350kw), medium frequency(15kwto 600kw), ultrahigh frequency(5kw-60kw) series. Can be used for hot forging, quenching machine tool guide rail, quenching, shaft on-line annealing, smelting, metal welding, etc. Can match CNC quenching machine tool, automatic feeding device. One-stop solution to all your induction heating demand.

We cooperated many well-known companies and domestic enterprises, such as Wangli group, xingyue group, Gree air conditioning, qingnian Auto and so on. Especially for non-standard and automation products have a strong design and processing capacity, the company has more than 100 sets of processing equipment to meet the needs of induction equipment to achieve the independent production of mechanical and electrical integration, the annual production capacity of 5, 000 units.

Depend on our advanced technologies, reliable solutions and excellent after-sales service, our induction heating machines are welcomed by domestic and abroad clients.

Welcome to enquiry more information, any questions or technique support, please contact us via e-mail for details. Your satisfaction are our team's goal.