Haisi Extrusion Plastic Compound Granulating Twin Screw Extruder

| Price: |

US $ 39999-99999/Set |

| Min Order: |

1/Set |

| Pay Type: |

L/C,T/T |

Product Specifications

| Prod Model: |

tsh series |

| Model: |

Tse-65 |

| Motor Power: |

75kw, 90kw, 110kw |

| Diammter: |

62.4mm |

| L/D: |

32-60 |

| Capacity: |

200-400kg/H |

| Warranty: |

1 Year |

| Product Type: |

Granulating Extruder |

| Feeding Mode: |

One Feed |

| Assembly Structure: |

Separate Type Extruder |

| Screw: |

Twin-Screw |

| Engagement System: |

Intermeshing |

| Screw Channel Structure: |

Deep Screw |

| Exhaust: |

Exhaust |

| Computerized: |

Non-Computerized |

| Type: |

Plastic Extruder |

| Plastic Processed: |

PP PE Pet PVC PS PA |

| Automation: |

Semi Automatic |

Product Description

Compound extruder/Twin screw extruder/Granulating line  1. Representive Material: Mixing nature-changing:PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA+Silicon rubber

1. Representive Material: Mixing nature-changing:PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA+Silicon rubber

PE,PA,PC,CPE+ABS,ABS+TPU,PBT+PET,PP+PE

Filling nature-changing:PE,PP,EVA,etc.+Calcium carbonate,talcum powder,titanic powder

PP,PA,ABS+ferrous powder,sulphuric powder,ceramic powder

Functional machine pellets:PP,PA,ABS,PBT,etc.+anti-burning agent and other auxiliary agents:combustion- supportong machine pellets

PE,PP,PS,etc+starch:de-composing machine pellets

PE+fog-preventing dipper,stabilizer:dual-prevention machine pellets

PE,EVA,ABS,etc+carbon black:black machine pellets

Colored machine pellets:PEMPP,ABS,AS PA,EVA ,PET+pigment and auxiliary

Intensified glass fibres and carbon fibres:PP,PBT,ABS,AS ,PA,PC,POM,PPS,PET,etc+long fibres,carbon fibres,crystals and so on 2. Features of twin screw extruder:>>> Screw: Modular princlpe , combinated according to different materials and its processing technic; Materials: W6Mo5Cr4V2; 58-60HRC ;

2. Features of twin screw extruder:>>> Screw: Modular princlpe , combinated according to different materials and its processing technic; Materials: W6Mo5Cr4V2; 58-60HRC ;

>>> Barrel: high nitride steel ; with bimetallic liners; 60-62HRC;

>>>Gearbox: high torque ; TYPE-B;

>>> Various kinds of Die head : Hydrualic screen changer ; Quick open Die; Hot face cutting Die head ;etc

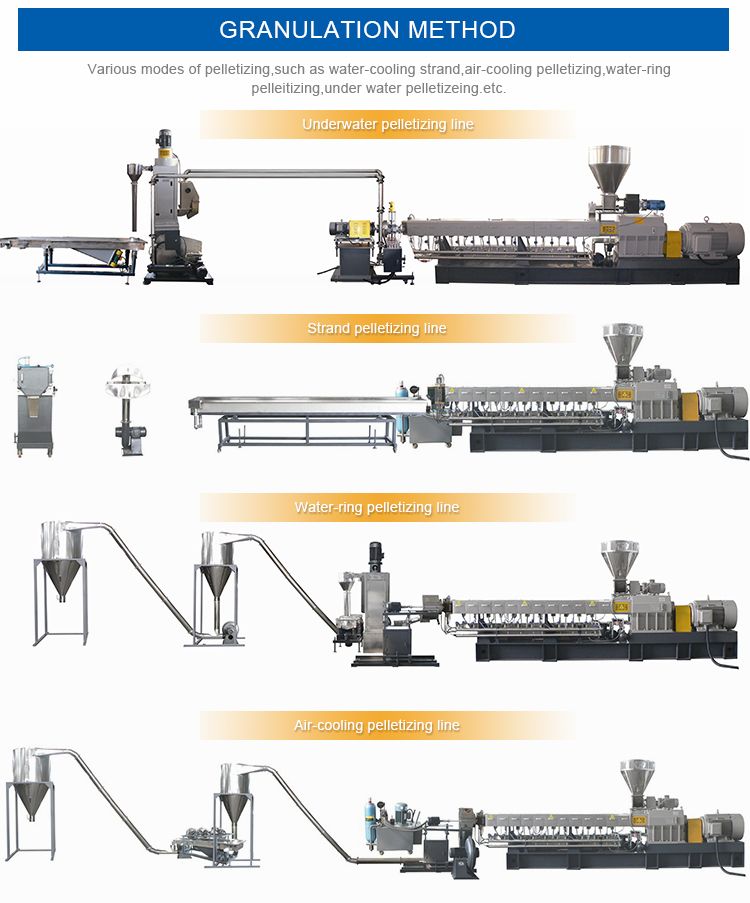

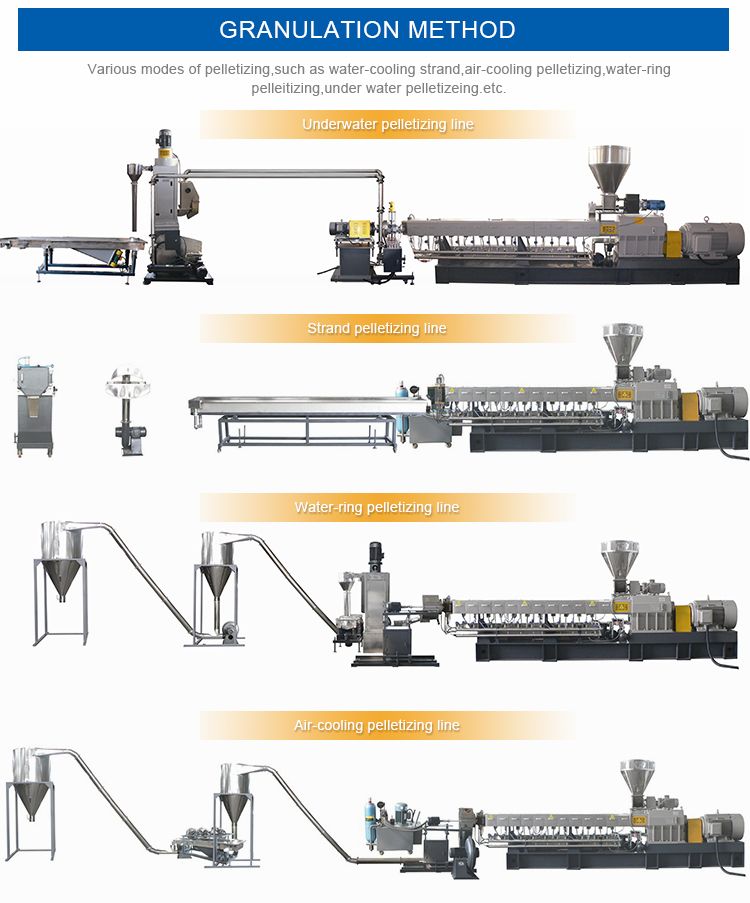

>>> different kinds of granulating line for compound:

Water cooling strand pelletizing line;

Air cooling hot face granulating line;

Water ring hot face granulating line ;

Underwater granulating line ;

3.Parameter for extruder

3.Parameter for extruder | Model | Diameter | L/D | Screw rotary | Motor Power | Torque | Capacity |

| TSE-20B | 22mm | 32-44 | 600r/min | 5.5kw | 43 | 0.5-10 kg/h |

| TSE-30B | 31mm | 32-48 | 600r/min | 15kw | 119 | 5-30kg/h |

| TSE-40B | 41mm | 32-52 | 600r/min | 30kw | 239 | 90-150kg/h |

| TSE-52B | 51.5mm | 32-56 | 600r/min | 55kw | 438 | 225-300kg/ |

| TSE-65B | 62.4mm | 32-60 | 600r/min | 90kw | 716 | 200-300kg/h |

| TSE-75A | 71mm | 32-64 | 600r/min | 110kw | 1050 | 250-350kg/h |

| TSE-75B | 71mm | 32-64 | 600r/min | 132kw | 1050 | 300-600kg/h |

| TSE-75C | 71mm | 32-64 | 600r/min | 160kw | 1990 | 500-1000kg/h |

| TSE-95B | 93mm | 32-64 | 600r/min | 250kw | 2387 | 800-1200kg/h |

| TSE-95C | 93mm | 32-64 | 600r/min | 315kw | 2506 | 900-1300kg/h |

| TSE-120B | 133mm | 32-64 | 600r/min | 550kw | 7162 | 1500-2250kg/h |

Introduction and history:

Nanjing Haisi Extrusion Equipment Co., Ltd is a high-tech manufacturing and trading company in China. "Family" is our benchmark. We work efficiently and help each other whenever anyone is in need due to the same target, that is, to make best quality of extruders in China.

Our company is a professional manufacturer of granulating extruders for coloring/dyeing, filling masterbatch production, as well as plastic modification and compounding, plastic recycling. Innovative machines are built as per the concept of durability, high efficiency and economical power consumption. And we also have substantial experience in R&D, technique and after sales service. And for some materials, we supply turn-key project.

Company is in strict accordance with CE and ISO9001 quality certification system for production management. There are over 200 models of extruders and spare parts. Factory has CNC center, grinding machines, cutter, puncher, etc. To meet customers' requirements on extruders and spare parts.

Business scope and achievements:

All kinds of plastic extruder.

Our machines are widely used in China mainland, and have been exported to 20 countries and places over the world. Our annual production capacity is 240 sets plastic extruder in domestic countries and abroad! OEM service offered in granulating plastic extruder industry in consistence with specific requirement from both national and international customers.

Prospects:

Surely you will also get professional machines and characteristic services here. Let's create more together!

Characteristics of our machine:

Euro-style rectangle barrel, reflux refrigeration channel is optimized and disposed, which makes temperature difference in D areas smaller.

Innovated design of heater tightened style insures high efficiency of heat transfer and high longevity of heater.

According to the material and special technics demands, the material of cyliner can use high quality nitrided steel, corrosion proof or antifriction with corresponding process.

Various modes of pelletizing, such as water-cooling strand, air-cooling pelletizing, water-ring pelletizing, under water pelletizing, etc.

The screw elements and kneading blocks are designed, by precise processed, agile combination, with interchangeability, which can fulfill efficient self-cleaning, transmission, compounding, pressure-forming, etc. The screw is made of high tool steel 38 CrMoAlA or W6Mo5Cr4V2 by special heat-treatment, which is possessed with high corrosion-resistand and high functions.

The machines are designed by using the "toy bricks" principle, the screw configuration, barrel setup, L/D or mode of feeding and venting, screen changing, way of granulating, and the control mode can be optimally adjusted according to different material properties and requirements in consideration of the versatility in each general applications.

Metering feeders are equipped with single screw, twin screw, hollow screw, forced-feeding, side-feeding system, etc. To meet different requirements of feeding, such as powder, pellet, pump and liquid material.

New-style gear transmission system:

New-style project of parallel three-axises driving makes the convey axis, convey chain, decelerate and torque get together, which keep it compact, and the key bearings are imported.

The computer designs to potimize gear parameters and strenghthen safe overmeasure.

The selected material of drive components is dainty. Including super intention alloy cementiteing steel, cementiting and grinding technics, strengthening of tooth face. So they can ensure high torque, high precision and low noise.

Soakage and spraying lubriation integrate smoothly.