Categories

Categories

| Price: | US $ 3980/Piece |

|---|---|

| Min Order: | 1/Piece |

| Pay Type: | T/T,D/P,Western Union,Paypal,Money Gram |

| Prod Model: | ISO, CO, CE, BV |

|---|---|

| Key Word 1: | Liquid Packing Machine |

| Key Word 2: | Liquid Packaging Machine |

| Key Word 3: | Automatic Packing Machine |

| Material: | Stainless Steel |

| Automatic Grade: | Automatic |

| Application: | Oil |

| Driven Type: | Electric |

| Material Type: | Liquid |

| Packaging Material: | Plastic |

| Forming Species: | Filling and Sealing |

| Packaging Type: | Bags |

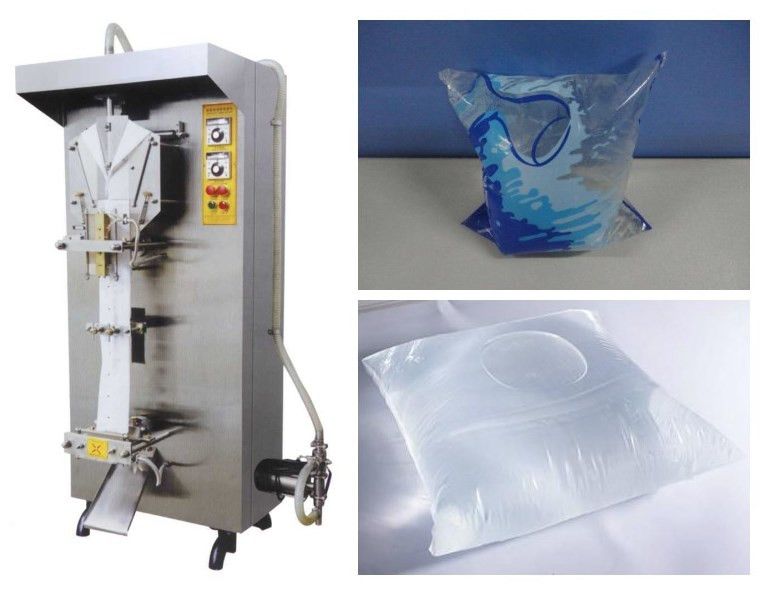

Introduction of liquid packing machine

This machine is suitable for automatic packaging of liquid of foods, medicine and chemicals,such as pesticide,

shampoo,body foam bath lotion, facial cream, ingredient oil, fruit sauce,tomato ketchup and honey shower gel,

skin lotion, toothpaste, cosmetic cream, fruit jam, edible oil, soy etc

Features of liquid packing machine

1) Be able to weight, bag-making, filling, sealing, cutting, lot number automatically.

2) It has color control system which can get the complete trade mark design

(Photo electricity control system).

3) The machine fix stepper motor controller, its advantage is precise, needless to adjust other parts

4) Intelligent temperature control by temperature controller to make heat balance better. Use bilingualdisplay screen

control system and stainless steel cabinet

5) Fine packaging performance, low noise, clear sealing texture and strong sealing performance

6) With safe plastic box on rotating blade to avoid hurting operators hands

7) With printer (to be able to code the date and batch number) and rotating blade (be able to adjust the length of bag

and shape of bag notch edge packing.

Descriptions

Three-step roller three-side sealing . Continuous running not only fast in speed, stable in function and low in noise, but also is firm in sealing, reliable in airtight, smooth and delicacy in bag's outlook, and extraordinary in packing efficiency.

An imported frequency changer is adopted for step-less speed adjustable, intelligent temperature controller regulates the temperature at the sealing. It is reliable in performance, convenient in operating.

Photoelectric tracking system is adopted to ensure the automatic correcting of the double face printing design on the packing bags, precise in counting.

Liquid & crystal touching display screen is adopted to realize the menus type speaks between man and machine.

It can do step-less adjust for the length of the bag without changing the mould. It is suitable to produce single machine with a great variety.

It is precise in measuring and able to fill material in high temperature, more suitable for high-speed packing machine.

Scope of application

our machine is mainly used to pack products as follows: salad oil, soy sauce, vinegar, cream and so on

Main character:

1. PLC control the length of the bag,(width should be fixed), operation is easy, bag making is accurate.

2. Photo-electricity sensor automatically tracking to prevent from wrong action and to control the length of bag.

3. Step-less speed control and two heat control.

4. Plc control the step motor, accurate filling, easy to operate, running is stable.

5. Maintenance is convenient.

6. According to GB/T173131998 Standard.

7. Packing material: PET/PE, Paper/PE, PET/AL(PET-AL)PE, OPP/PE etc can be applied to heat seal. (PET : is polyester, PE: Polyethylene.)

| Model | GMEU-150Y |

| Max film width | 240mm |

| Bag making Length | 70-150mm |

| Bag making Width | 50-110mm |

| Packing speed | 30-80bags/min |

| Weight | 320kg |

| Dimension | 600*790*1780mm |

| Power | 220V 50/60Hz 1.5Kw |