Product Specifications

| Prod Model: |

CK6150 |

| Max. Swim Over Bed: |

500mm |

| Size Of Three-Jaw Chuck: |

250mm/10inch |

| Spindle Bore: |

82mm |

| Taper Of Spindle Bore: |

Type of Spindle Head D-8 |

| Taper Of Tailstock Quill: |

Mt5 |

| Max. Range Of Tailstock Quill: |

150mm |

| Motor Power: |

7.5kw |

| Voltage: |

380V or as Your Request |

| System: |

Fanuc,Siemens,GSK |

| Range Of Spindle Speed: |

150-2000rpm |

| Type: |

Horizontal Lathe |

| Processing Accessory: |

Chuck CNC Lathe |

| Power Source: |

Electric |

| Controlling Mode: |

CNC |

| Automatic Grade: |

Automatic |

| Setting Mode: |

Floor-type |

| Precision: |

High Precision |

| Tool Holder: |

4 |

Product Description

Company informationTaian Crystal Machinery Co., Ltd., is a modern and high- tech company which is a professional manufacturer of CNC LATHE, CNC MILLING, CNC MACHINE CENTER . With 5,000sqm workshops and offices, we have more than 15 years experiences in cnc machine research and production.Our machines have been exported more than 40 countries.we welcome all customers and friends to come to our company!

Our guarantee1.We are cnc machine manufacrurer, can provid the high quality, competitive price and good after-sale service.

2.We have our own technical team, can provide the customized solutions according to your request.

3.We go the full 24-hour performance and accuracy test before shipment.

4.Warranty is one year; we would offer the parts. Quality problem is free of charge

during this period.

5.One year guarantee for whole machine expect of CNC system, which guarantee is

three years

6. 24 hours technical support e-mail.

7. User manual and detailed video.

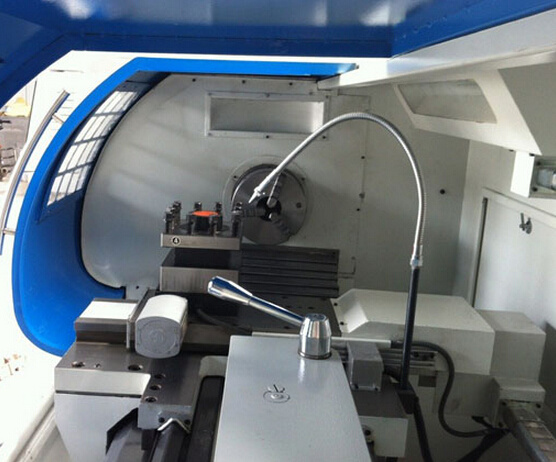

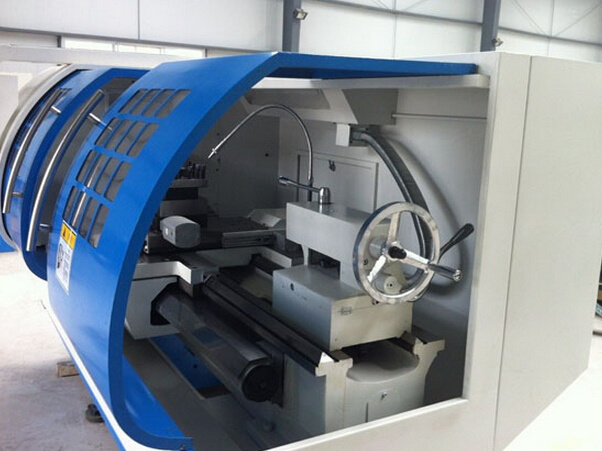

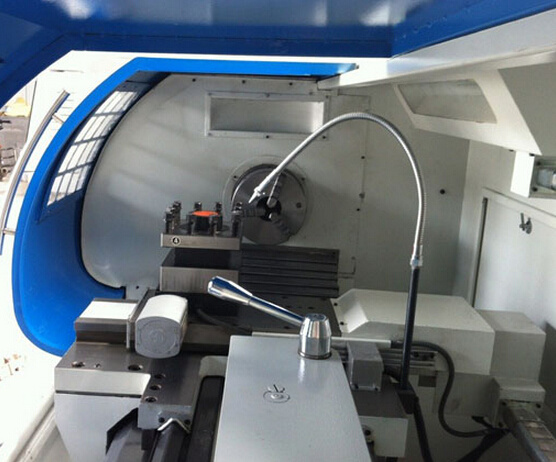

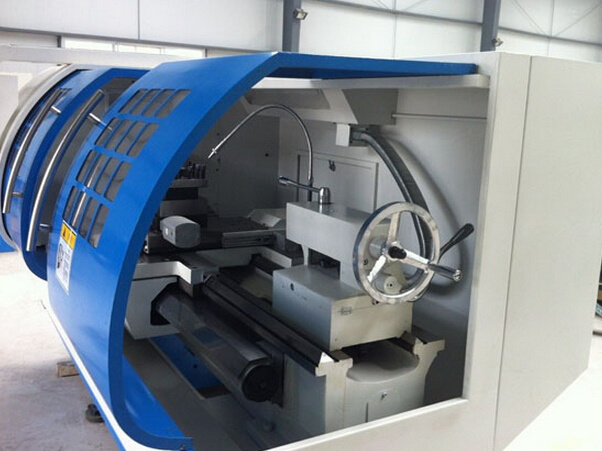

Standard configuration1.System:GSK928TD-L, servo motor and drive

2.Manual 3-jaw chuck, 4-station electric tool post.

3.Manual tailstock, Semi-Rugged

4.Cooling system;Lighten system;Automatic lubrication system

Optional configuration

1.Optional brands of CNC systems

SIEMENS,FANUC

2.Optional types of the tool post

Horizontal Six-station, horizontal eight-station

3.Optional types of the workpiece clamping

Hydraulic chuck,pneumatic chuck,spring chuck

4.Optional types of the tailstock

Hydraulic tailstock,pneumatic tailstock

5.Optional patterns of feeding

Automatic feeding(Customized programs alone)

Instructions of other devices1.Structure style of spindle

Independent spindle and frequency control

2.Protective cover and door

Metal plate cover and double protective door

3.Position of CNC system

On the left side, rotation type

4.lighting system

Standard T8 fluorescent lamp

5.Cooling system

Water cooling

6.Lubrication system

Automatic lubrication controlled by microcomputer

7.Brands of motor-driven tool carrier

Hongda and Sanhe

8.Type of cabinet base

Overall cast iron

Specification| ITEMS | Specifications |

| Max. swim over bed | Φ500mm |

| Max. swim over carriage | Φ280mm |

| Max. length of work piece | 1000mm |

| Width of the machine | 400mm |

| Size of three-jaw chuck | 250mm |

| Range of spindle speed | 150-2000rpm |

| Spindle bore | Φ82mm |

| Taper of spindle bore | Type of spindle head D-8 |

| Stations of tool carrier | 4/6/8 |

| Min. setting unit of motor | (Z) long 0.001mm,

(X) cross 0.001mm |

| Moving speed of post | (Z) long 8 m/min,

(X) cross 6 m/min |

| Taper of tailstock quill | MT5 |

| Max. range of tailstock quill | 150mm |

| Motor power | 7.5KW |

| Packing size(length ×width ×height) | 2970 mm×1400mm×1650mm |

| Net weight | 3500kg |

Taian Crystal Machinery Co., Ltd., is a modern and high- tech company which is a professional manufacturer of CNC machining Center, CNC Lathe Machine, Wheel Lathe machine With 5, 000sqm workshops and offices, we have more than 15 years experiences in CNC machine research and production. Our machines have been exported more than 40 countries. We welcome all customers and friends to come to our company!

Our team have great experience on manufacturing and exporting. Our service department has experienced technicians that can offer you answers to your technical questions, and in many cases, solve your problem effectively over the phone.

We are dedicated to provide customers with the best, highly value added machines. We have earned a strong reputation in design and manufacturing of a wide variety of CNC machine tools. We continuously improve the performance level of our machines, strengthen our quality control system, and offer worldwide support services. Our dedication to the global marketplace will create a new era of CNC machine tools.

Furthermore, we are serious about quality, customer input, and reacting to market demands. Our fully equipped quality control department performs the final inspection of the machine and in process inspection of parts. Our quality control personnel are well trained to conduct rigorous inspections by using precision, sophisticated instruments. We deeply believe that quality is the life of our company and customer service is the power that drives our company forward. We are also looking for cooperation with professional dealers in the world. This would make us to create a new opportunity in certain area and offer top service quality as we have in China.