Categories

Categories

| Price: | US $ 10000/Set |

|---|---|

| Trade Terms: | FOB,CFR,CIF |

| Min Order: | 1/Set |

| Pay Type: | L/C,T/T,D/P,Western Union,Paypal |

| Prod Model: | XG-120kw |

|---|---|

| Markets: | North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Warranty Period: | 12 Months |

| Application Case: | Induction Welding |

| Condition: | New |

| Input Voltage: | 3*380V |

| Maximum Input Current: | 180A |

| Rated Power: | 120kw |

| Output Frequency: | 20-80kHz |

| Cooling Method: | Water Cooling |

Digital High Frequency Induction Welder for Metal Brazing Welding

High Frequency Induction Welder Part:

1.Advantages:

2.Technical Parameters:

3.Working Environment:

4.Standard Digital High Frequency Induction Welder picture:

Induction Machine Transformer

1.Transformer parameters:

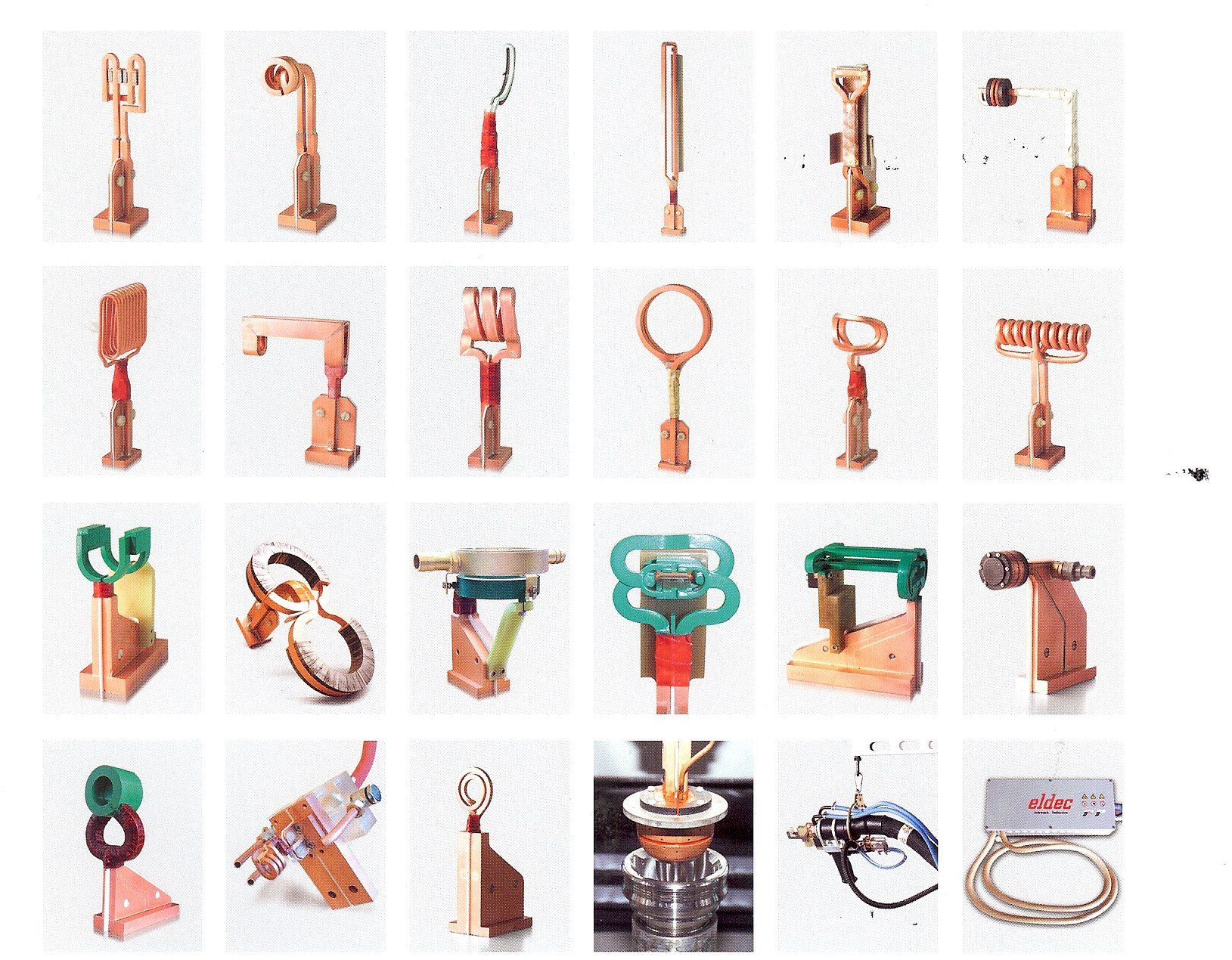

Induction coil introduction

1.Technical parameters:

made by the customers' detailed technical requirement.

2.Features:

Ø Magnetic field distribution and design are precise, high efficient and energy-saving.

Ø Use with the magnetizer, easy to adjust the magnetic field intensity.

Ø Easy disassembly, exchangeability.

Ø Fastness and durability.

3.Induction coil applications:

Crankshaft induction coil, end-face induction coil, hub bearing induction coil, caterpillar track section hardening induction coil, inner hold induction coil, gear induction coil, shaft neck hardening induction coil, 3m inner hold hardening induction coil, crankshaft with fillet induction coil.

4.Induction coil pictures:

Closed-loop Water Cooling System:

1.Technique data

Input voltage:three phase 380V±10%

Rated voltage:three phase 380V 50Hz

Cooling capacity:31100Kcal/h-1806000Kcal/h

2. Features

Cooling water tower movement all adopt in thermal efficiency high copper tube, let the working fluid (water or other liquid) in its line through, through the fan and air for natural heat exchange, one-time finish. It is not only energy conservation and environmental protection,but also tube is clean and unobstructed, reduce the failure rate, prolong the useful life of the equipment. Closed circulating cooling reduce pipe corrosion and scaling, do not need to pool, covers an area of small, convenient to move, energy saving, simple operation.

Application Fields:

1.Heat Treatment

2.Wire heating ,strip steel heating,panel material heating

3.Bar forging heating,stainless steel heat treatment, pipe material heating, forging heating, pipe heating bending.

4.Oil pipe heating, pipe preheating heat treatment.

5.Braze welding, precious metal melting, hot charging and hot discharging.

6.Cellphone and portable computer mould heating, induction coating and so on.

Customer service:

Call or e-mail us any time. Before you place your order, we will be happy to discuss your detailed requirements with you and help you find a selection of machine that is just right for your market.

Quick Delivery:

With your wide requested of faucets with even less than our MOQ, we are able to fulfill most requests within short days of your order.

Promise:

Customers Satisfaction, provide good quality and reasonable price and constant after sale service to be engaged in 100% of us .

Package:

Package: plywood cases.

Shipment: By sea or by air

FAQ

1. When the company Established?

Answer: Its in 2000.8.1.

2. What's your frequency level?

Answer: frequency level from 0.1-600KHZ

Power level from 8kw-1000kw

3.What's your circuit mode?

Answer: IGBT series and parallel.

4.Contact details:

Answer: before sales service hotline: 0086-15237153056

After sales service hotline: 0086-371-68872076