Product Specifications

| Prod Model: |

XCG-300B |

| Markets: |

North America,South America,Eastern Europe,Africa,Oceania,Mid East,Western Europe |

| Warranty Period: |

12 Months |

| Application Case: |

Hardening, Heat Treatment |

| Condition: |

New |

| Input Voltage: |

AC~ 3*380V |

| Maximum Input Current: |

450A |

| Rated Power: |

300kw |

| Output Frequency: |

20-80kHz |

| Efficiency: |

96% |

| Duty Cycle: |

100% |

| Cooling Method: |

Water Cooling |

Product Description

Digital High Frequency Induction Heating Equipment

1.Advantages:- More reliable: the cabinet is well sealed, no failure all year, IGBT never burst.

- More Intelligent: Inverter power factor can reach 96%.

- More Intelligent: Control precision can reach 0.1%, all load can be automatically matching.

2.Technical Parameters:- Power range: 100-2000KW

- Frequency range:0.2-50KHZ

- Power Factor: >0.96

- Control Precision:0.1%

- Resonance Mode: Series resonance, parallel resonance, mix resonance

- Application field: heat treatment(hardening, tempering, annealing, hardening &tempering),hot forging, melting, crystal growth, induction evaporation, forging, casting and so on.

3.Working Environment:- The power supply voltage big fluctuation.

- Product variety

- High quality requirement

- Products require high consistency

4. Induction Heating Machine Display:

Induction Machine Transformer

1.Transformer parameters:- Capacity range: 300KVA--3000KVA

- Frequency range: 0.1KHz--500KHz

2.Induction machine transformer features:- General Transformer----convenient operation, single turn ratio, need to adjust the induction coil to match the machine.

- Multi-ratio Transformer----suitable for all kinds of induction coils, used for all kinds of occasion, just need to adjust the turn ratio is ok.

- Coaxial Transformer---energy concentration, small volume, but the turn ratio is single, better suitable for fixed load.

Induction coil introduction

1.Technical parameters:

made by the customers' detailed technical requirement.

2.Features:

Ø Magnetic field distribution and design are precise, high efficient and energy-saving.

Ø Use with the magnetizer, easy to adjust the magnetic field intensity.

Ø Easy disassembly, exchangeability.

Ø Fastness and durability.

3.Induction coil applications:

Crankshaft induction coil, end-face induction coil, hub bearing induction coil, caterpillar track section hardening induction coil, inner hold induction coil, gear induction coil, shaft neck hardening induction coil, 3m inner hold hardening induction coil, crankshaft with fillet induction coil.

4.Induction coil pictures:

CNC Hardening Machine Tool

1.CNC Hardening Machine Tool Technical Parameters:- Ø Vertical type universal machine tool: Φ10-Φ200,500-3000mm

- Ø Horizontal type universal machine tool: Φ50-Φ200,500-10000mm

- Ø Disk type universal machine tool: Φ50-Φ1000mm

Special-purpose machine tool: can design and make as the customers' requirement.

2.CNC Hardening Machine tool Features:

Ø Running with high precision

Ø Control function is perfect, can use single shaft, multiple shaft control system.

Ø Can use together with the power supply power, meet the same part different power requirement.

Ø One-touch operation

3.Vertical type machine tool, horizontal type machine tool, disk type machine tool pictures:

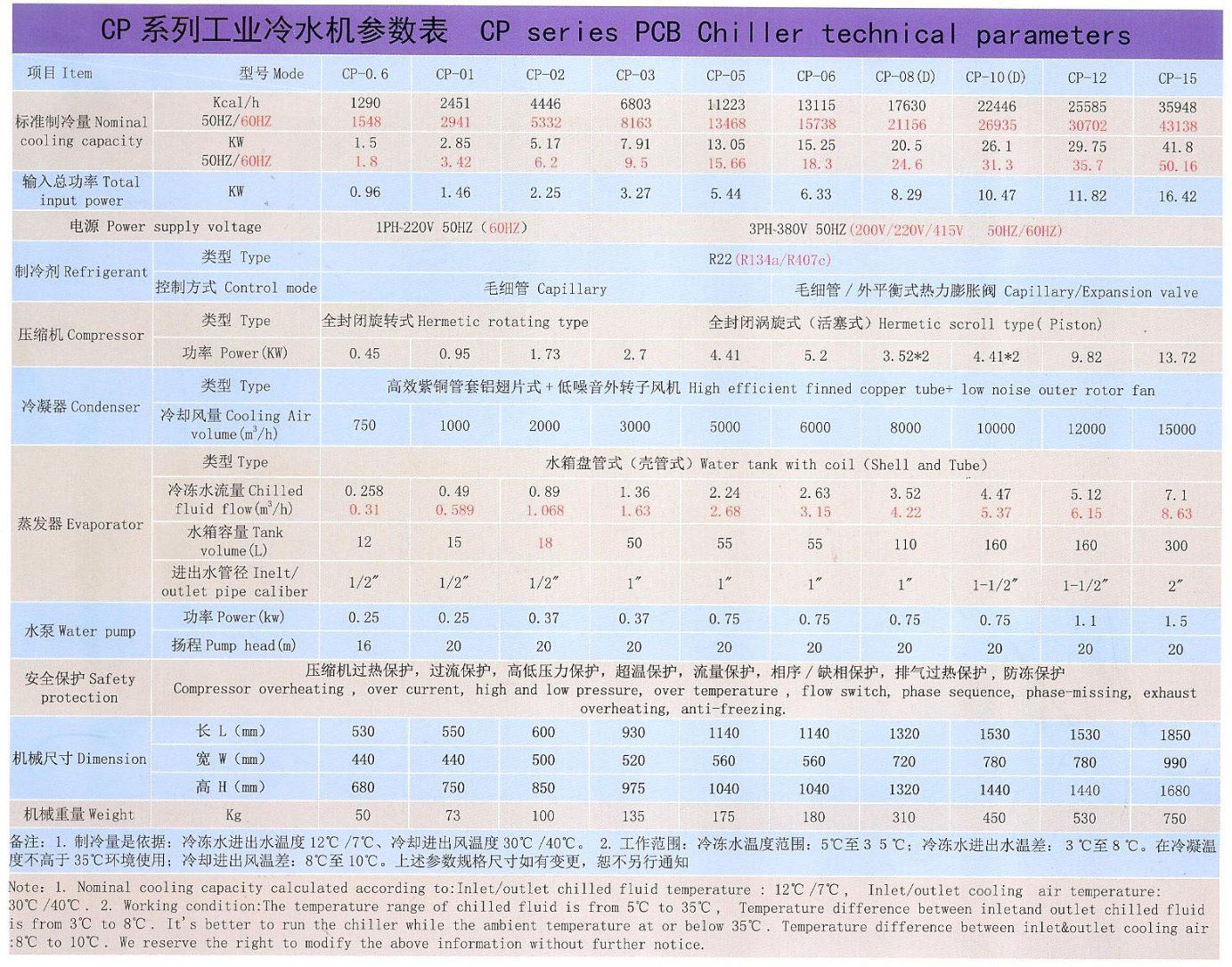

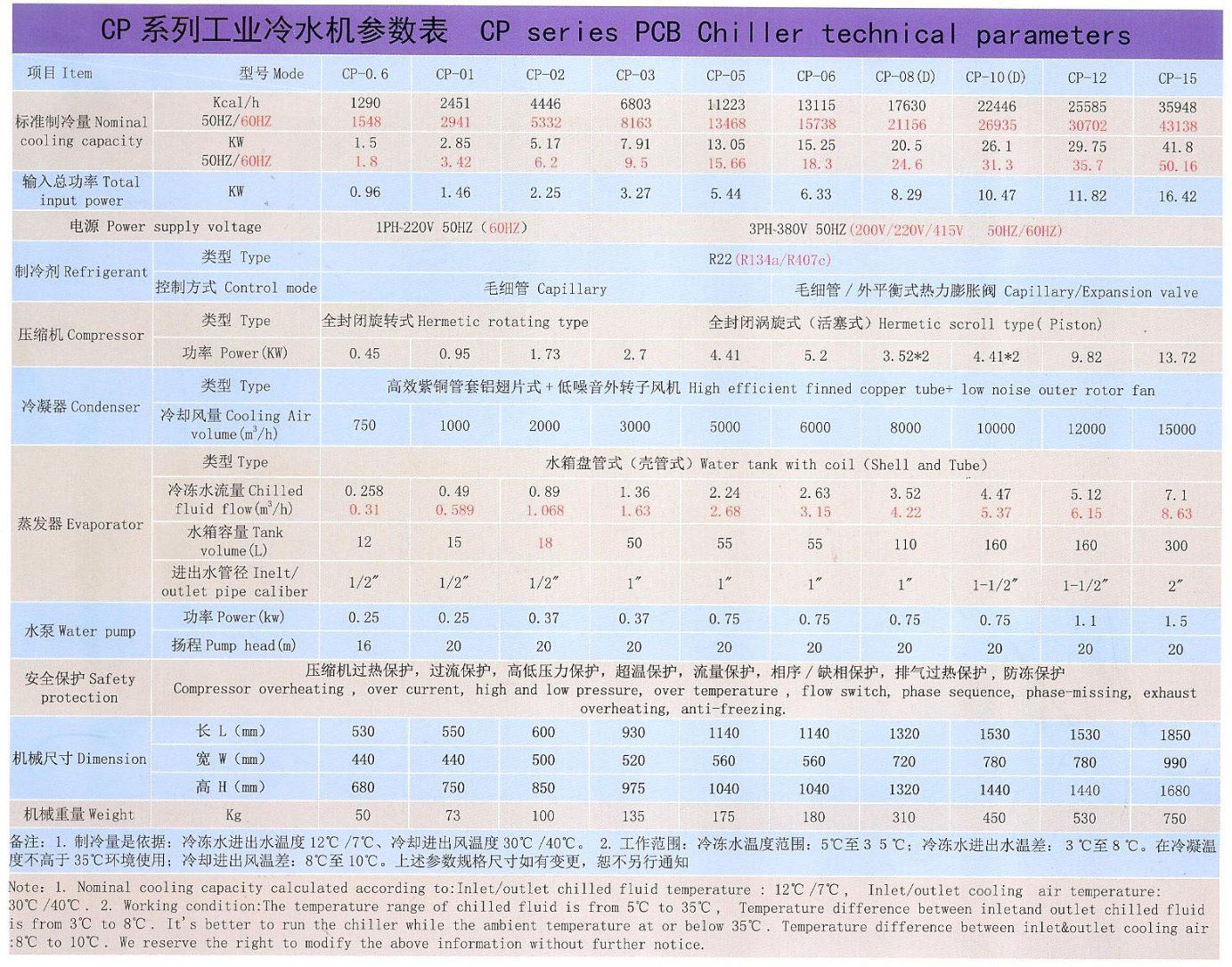

Industrial chiller

Small Industrial Chiller Features:

•Original American and Japanese compressor with built-in safety protection, low noise, power-saving and durability.

•Italian water pump with big flow, high efficiency and long durability.

•Microcomputer PLC control system and precise digital control system, making temperature tolerance at ±1ºC. Push button operation and work normally without professional personnel.

•Famous "SCHNEIDER" electrical components and guarantee stability and long service life.

•With DC circuit, water pump stops when CNC spindle not work to avoid condensate water.

•Stainless steel thick tank evaporator with built in auto filling water devices, convenient and quick for maintenance.

•Static spraying casing with compact size and easy dismounting plate.

Small Industrial chiller technical parameters:

Application Fields

1.Heat Treatment

2.Wire heating ,strip steel heating,panel material heating

3.Bar forging heating,stainless steel heat treatment, pipe material heating, forging heating, pipe heating bending.

4.Oil pipe heating, pipe preheating heat treatment.

5.Braze welding, precious metal melting, hot charging and hot discharging.

6.Cellphone and portable computer mould heating, induction coating and so on.

Zhengzhou Kechuang Electronic Co., Ltd. is a high-tech enterprise specialized in induction heating equipment and related complete equipment system. It is the pioneer and pilot of China's induction heating industry. Products are widely used in mechanical manufacturing, aerospace, petrochemical, metallurgy, microelectronics, light industry, electric power, scientific research and other fields.

Since company establishment, has always been committed to provide users with excellent products and service, and regard the "scientific &technological innovation" as the driving force of enterprise development, nearly 20 years to focus on research induction power supply technology and its application in the field of metal heating, successively obtains more than 60 national patents and software copyright, won several national and provincial science and technology innovation award, has developed hundreds of high performance, high precision, high efficiency and energy saving, safe and reliable intelligent products, through the ISO9000 quality management system and European CE product certification.

Our company has the excellent technical team, deep industry accumulation, can provide the professional product solution for the user. At present, there are many well-known users in more than 20 countries and regions including Asia, Europe, America, Africa Oceania and so on.