Categories

Categories

| Price: | US $ 2.9-4.3kgs |

|---|---|

| Min Order: | 5000kgs |

| Pay Type: | L/C,T/T,Western Union |

| Prod Model: | APES-57 |

|---|---|

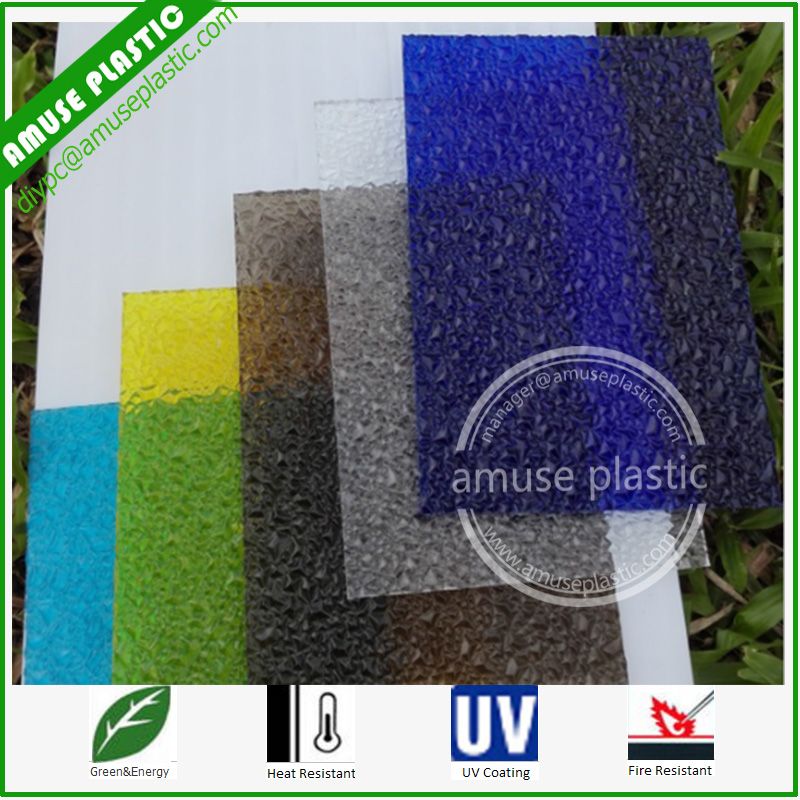

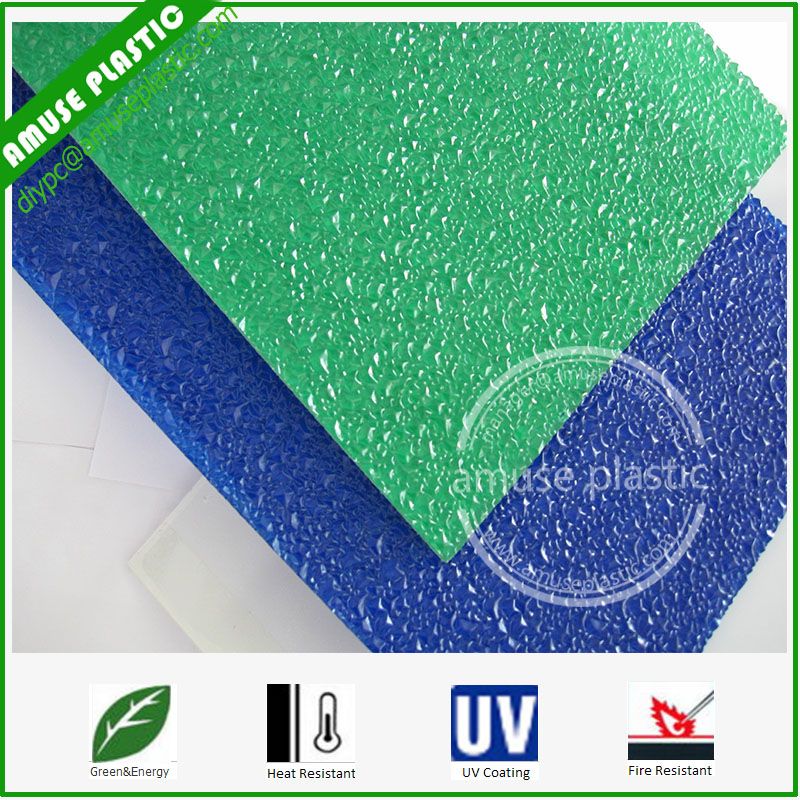

| Colors: | Clear, Blue, Opal, Green, Lake Blue, Customized |

| Small Samples: | Available with Freight Collected |

| UV: | with UV Protective Coating |

| Light Transmission: | From 10% to 85% |

| Quality: | Grade a |

| Service Temperature: | -40 to 120°c |

| HS Code: | 3920610000 |

| Material: | PC |

Product Features:

1. Light trasmission

2. Impact resistance: 80 times that of glass, 15 times that of acrylic sheet.

3. Temperature resitance range: -40 to 120°c.

Soften temperature : 148ºC

4. Light weight: only 1/12 of the weight of glass at same thickness.

5. Ultraviolet resistance: with UV protective layer.

6. Weather proof

7. Flame resistance: B1 grade

8. Sound and Heat proof

9. Environment friendly

Polycarbonate Characteristics:

| No. | Characteristics | Unit | Data |

| 1 | Impact Strength | J/m | 850 |

| 2 | Light Transmission | % | 85 |

| 3 | Specific Gravity | g/cm3 | 1.2 |

| 4 | Coefficient of Thermal | mm/m °c | 0.065 |

| 5 | Service Temperature | °c | -40 to +120 |

| 6 | Heat Conductivity | W/m2°c | 2.3-3.9 |

| 7 | Tensile Strength | N/mm2 | >60 |

| 8 | Flexural Strength | N/mm2 | 100 |

| 9 | Modulus of Elasticity | MPa | 2400 |

| 10 | Tensile Stress at Break | MPa | >65 |

| 11 | Elongation at Break | % | 100 |

| 12 | Specific Heat | kj/Kgk | 1.17 |

| 13 | Heat Deflection Temperature | °c | 140 |

| 14 | Effect of Soundproof | dB | 3-4 |

PC Emboosed Sheets Details:

Thickness: 2-8mm

Size: 1.22m, 1.56m, 1.82m, 2.1m for width, no limit for length.

Colors: clear ( transparent ), blue, green, lake blue, opal, bronze for standard, others can be customized.

Lead time: 5 days for one full container at 30% TT deposit received

MOQ: 1x20GP CTN

Packing: flat sides with PE Protective films

Applications:

1. Doors, windows.

2. Skylight, lighting for corridors, balcony, passages and subway entries, walkways.

3. DIY awning, canopy

4. lights covers.

5. Industrial Roofing and Glazing

6. Swimming Pools roofing/cover/sheet

Loading:

PC Sheets Storage:

Stored on flat surfaces or wooden bearers with 100mm minimum bearing surface, placed at centre not exceeding 1m.

Make sure the place where you stored is dry, shaded and well ventilated area.

Use an opaque cover (not under flexible PVC coverings), tightly secured, protecting from wind, rain and sun.

Don't store under direct sunlight or without shelter from rain. Indoors torage is always preferable.

PC Sheets Installation:

Step 1: Use screws to attach the base connecting profiles to the roof beams. Make sure the screws not bend, tear or exert excessive pressure on the profile.

Step 2: Place the sheet on top of the base profile support edges, with the side covered by the printed protective film facing upwards.

Step 3: Slide the base under the sheet and attach it to the beam.

Step 4: Place the side spacer profile onto the roof beam and attach the cap to the base by hammering into place with a rubber mallet.

Kindly Remark:

1. As expandable, the drilling diameter must be 1.5 times than that of the bolt.

2. Do not use gaskets made of PVC.

3. PC Sheets can't be installed too tight because there will be thermal expansion and contraction which will adversely affect the installation.