Product Specifications

| Prod Model: |

SGZ800-N |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Application Industry: |

Chemical Industry |

| Discharge Type: |

Automatic Discharge |

| Speed: |

1200 R/Min |

| Power: |

7.5 Kw |

| Type: |

Centrifuge |

| Condition: |

New |

| Object: |

Granule,Such as Salt |

Product Description

>>>Main FeaturesSGZ model tripod scraper discharge automatic centrifuge is a filtration automatic centrifuge typical of

scraper Bottom Discharge, intermittent operation, process control, through application of control with

advanced PLC programmable controller and adoption of frequency governor and brake braking unit

as well as hydraulic or pneumatic device combinations, operated in the forms of single machine or

central-control computer network. The hydraulic and electrical control system automatically fulfills feed,

separation, rinse, dehydration, discharge, and other working procedures, able to achieve remote operation,

and able for adaptation to use for separation of suspension liquids containing solid-phase granules of

0.05-0.15 particle size, especially adaptable to separation of materials with strong thermal sensitivity,

breakage of crystal grains not allowed, not easy to approach manually, fully suitable for the flammable

and explosive, toxic, and corrosive industrial sites. This machine is characterized by advantages of high

automation degree, large disposal amount, good separation effect, stable running, and easy operation,

able to achieve a multif-aceted cleaning, safe and reliable, in compliance with GMP standards.>>>Main Application Extensively applied to filtration of suspension liquids with solid phase as granules.

Chemical Industry: Gypsum and oxalic acid

Food Industry: Sodium glutamate and food additives

Pharmaceutical: Vitamin and antibiotic

Mine and Metallurgy: Copper, zinc, minerals, and metal refining

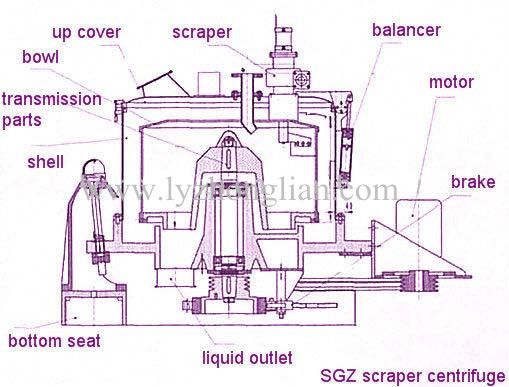

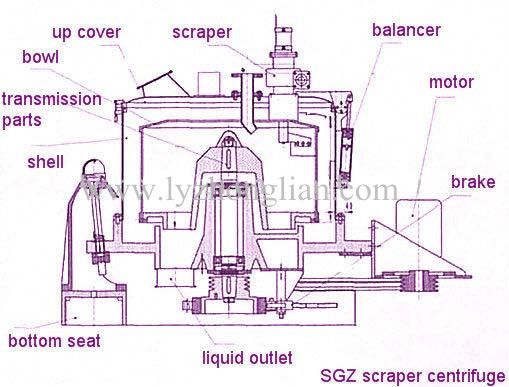

Environmental Protection: Pure water sludge and sewage sludge.>>>Structure and Principle

The motor actuates the bowl to rotate around spindle through transmission system. The separated

suspension liquid enters into bowl through the feed pipe on top, and falls on the material distribution tray.

Under the function of centrifugal force, it flows to the wall of bowl, and the liquid phase is thrown into the

space of machine cabinet through gauze and filter opening on the wall of bowl and collected on the underpan,

to be discharged via liquid drain pipe, while the solid phase is retained on the inner side of the filter gauze.

If rinse is required, washing water is to be added for rinse through washing pipe.

After dehydration is completed, the bowl will rotate at a low speed, and the automatic scraper system will act

to scrape off the crusher solid-phase substances, to be discharged through the Bottom Discharge outlet of bowl.

>>>Technical Parameters

Bowl | Diameter | 800 mm |

| High | 400 mm |

| Filter area | 1.0 m2 |

| Liquid blocking plate diameter | 560 mm |

| Working Volume | 90 L |

| Max feeding capacity | 135 kg |

| Rotate Speed | 1200 r/min |

| Separation factor | 640 |

| Discharge type | Hydraulic scraper |

| Pneumatic scraper |

| Air pressure | 0.3-0.6 Mpa |

| Brake mode | Electric braking |

| Motor Model | YB132M-4 |

| Motor Power | 7.5 kw |

| Motor Rotate Speed | 1460 r/min |

| Weight | 1800 kg |

>>>Packaging & ShippingPackaging: Inner packing:Spare parts are placed neatly in a box

Outer packing:Standard Exported Wooden Case

Shipping: FOB & CIF & CNF (FOB:Usually,we deliver the product to DaLian port,LiaoNing,China)

>>>Our Services1)Features & Advantages:

Manufacturer & Produce as required & Widely saled around the world

Good quality with GMP,SGS,ISO9001 Standard & Competitive price

2)Highly attention & Timely Answer:

Your Inquiry or email will get reply within 12 hours

Your technical problem will get reply within 24 hours

3)Professional Technical Support :

Any problem,our engineer will help you to solve it via email,telephone,video,etc

Even,Our technicians could be dispatched for overseas service

4)Stock:Abundant spare parts in stock are available to provide,

which means the replacements can be shipped to you right away

>>>Company InformationWelcome to visit our company show:

http://zonelink.en.made-in-china.com/ http://www.lyzhonglian.com/Liaoyang Zhonglian Pharmaceutical Machinery Co.,Ltd.was established in October 2001,

up to now has fifteen years of professional production experience and perfect testing means.

The company is located in China's earliest engaged in the centrifuge production liaoyang city,

liaoning province, and covers an area of ten thousand square meters, product workshop area

of seven thousand square meters,is specialized engaged in the centrifuge equipment and

pharmaceutical machinery manufacturing enterprises.

Products have been widely used in pharmaceutical, chemical, food, smelting, and many other

industries,through the unremitting efforts of all staff has been formed its own sales network

at home and abroad, products exported to north American countries such as the United States,

and Mexico,southeast Asian countries such as Thailand, Singapore, Malaysia, Indonesia,

east Asian countries such as Korea,South American countries such as Venezuela, Peru .

With reliable quality and excellent after-sales service, the company won the support and

praise of the broad masses of overseas customers .

Two new hard horizontal support balance machines were purchased, balance of centrifuge

main pieces of drum quality correction, effectively guarantee the balance of a drum. Our staff

are committed to the production and sales of centrifugal separation machinery, creating

suitable model for all kinds of material separation equipment!

Situated in Liaoyang city of Liaoning province, earliest engaged in the production of centrifugal machinery in China, Liaoyang Zhonglian Pharmaceutical Machinery Co. Ltd specially engage in the production of centrifugal equipments - disc centrifuge, tubular centrifuge, tripod centrifuges and other pharmaceutical machinery, is one of the backbone of the pharmaceutical industry.

The company was founded in October 2001, is located in the middle of Liaoyang Fanrong Road Industrial Development Zone, covers an area of 10, 000 square meters, production workshop area of 7000 square meters, has many years of professional production experience, the total assets of 8 million yuan, fixed assets original value of 2.4 million yuan, employs 120 people, including four managers, sales staff of eight, two senior engineers, senior technical staff of five, are the backbone of the young, specialized in the manufacture of centrifuge machines, processing equipment excellent existing lathe, milling machine 24 sets of machining equipment were purchased in 2000 after the new equipment, advanced equipment, high precision, the company has improved detection methods, the existing on-site balancing machine, purchased this year, supporting a balanced horizontal rigid Machine 2 sets of main parts of the centrifuge bowl balance for high-quality calibration and effective to ensure the balance of the bowl, the company created a high-tech R & D disc separator, tubular separator, flat centrifuge, tripod centrifuge centrifuges and other equipment, and its continued improvement and perfection. Now for the pharmaceutical, chemical, food, metallurgical and other industries has been widely applied, staff of our company after seven years of efforts, has formed its own sales network nationwide is now the market has formed a fixed customer base, while at 2007 also carried out export business, the production of centrifuges products have been exported to foreign countries, the company with reliable quality, excellent service, has won user support and praise.

We regard customer satisfaction and market cultivation as its central job of service and provides first class product and personalized service. Senior technical engineers and production backbones go deeply into the market for investigation. And tap the potential demands of customers at the first time. We provide customers with perfect solutions.