Categories

Categories

| Price: | US $ 2.3-2.7KG |

|---|---|

| Min Order: | 500KG |

| Pay Type: | L/C,T/T,Western Union,Paypal,Money Gram |

| Prod Model: | ZHL-Furniture Series |

|---|---|

| Product: | Aluminium Profile |

| Material: | 6063-T5, 6061-T6, 6463-T5, 7075-T6, 6082 |

| Surface Treatment: | Anodized, Electrophoresis, Powder Coated, Wood Gra |

| Deep Process: | Drilling, Tapping, Punching, Cutting, Bending |

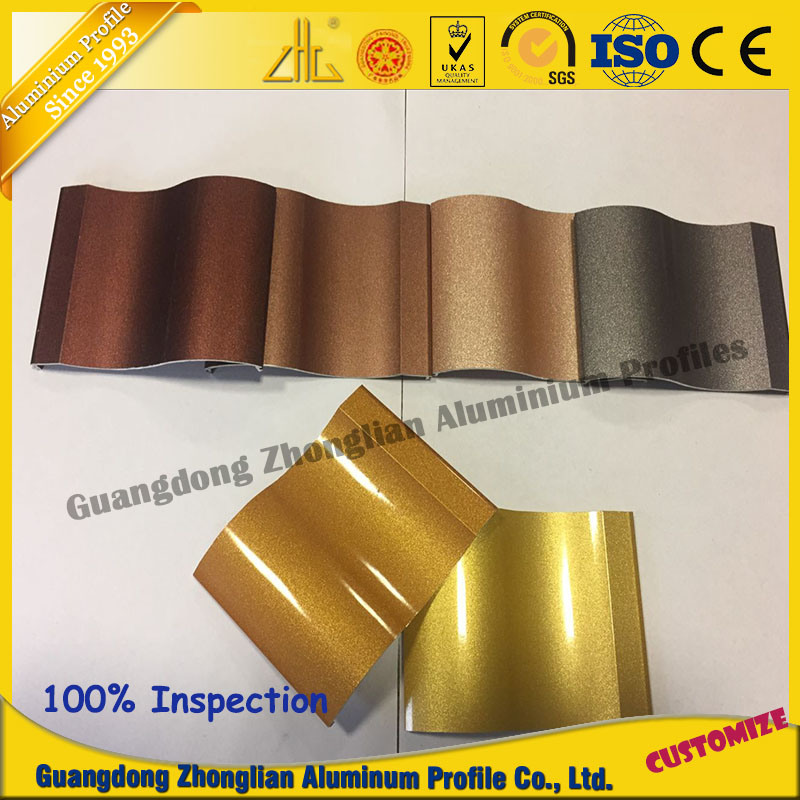

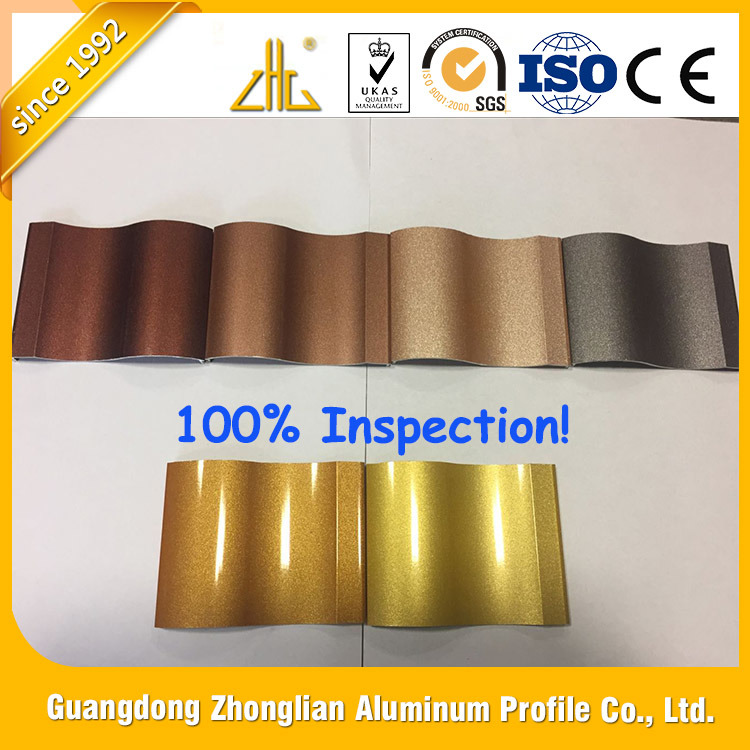

| Color: | Customized (Various Colors Are Available) |

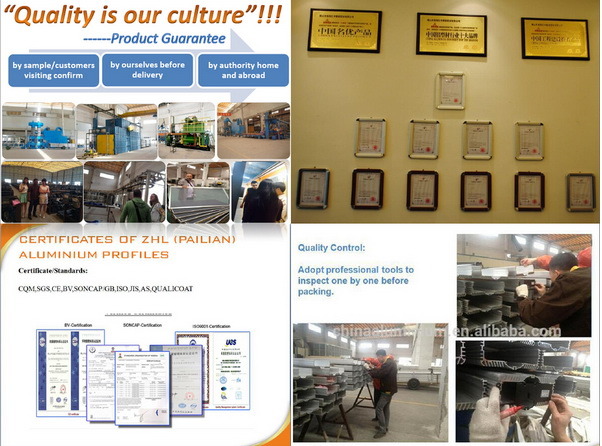

| Standard/Certificate: | Cqm, SGS, Ce, BV, Soncap / GB, ISO, JIS, as, Nzs |

| Port Of Loading: | Shenzhen/ Guangzhou/ Foshan |

| Payment: | T/T 30% for Deposit, Balance Before Delivery |

| Guarantee: | Surface Color Can Be Stable for 10-20 Years Indoor |

| Delivery Time: | 25-30 Days After Confirming Sample by Buyer |

| Application: | Transportation Tools |

| Grade: | 6000 Series |

| Temper: | T3-T8 |

| Window & Door Aluminium Profile: | 60 Series |

| Alloy: | Alloy |

| Alloying Ingredient: | 6063 |

| Certification: | TUV |

| Polished Aluminum Profile: | Mechanical Polishing |

| Shape: | Customized (a Wide Range Shapes Are Available) |

| Surface Finishing: | Anodized, Powder Coated, Wood Grain, Customized |

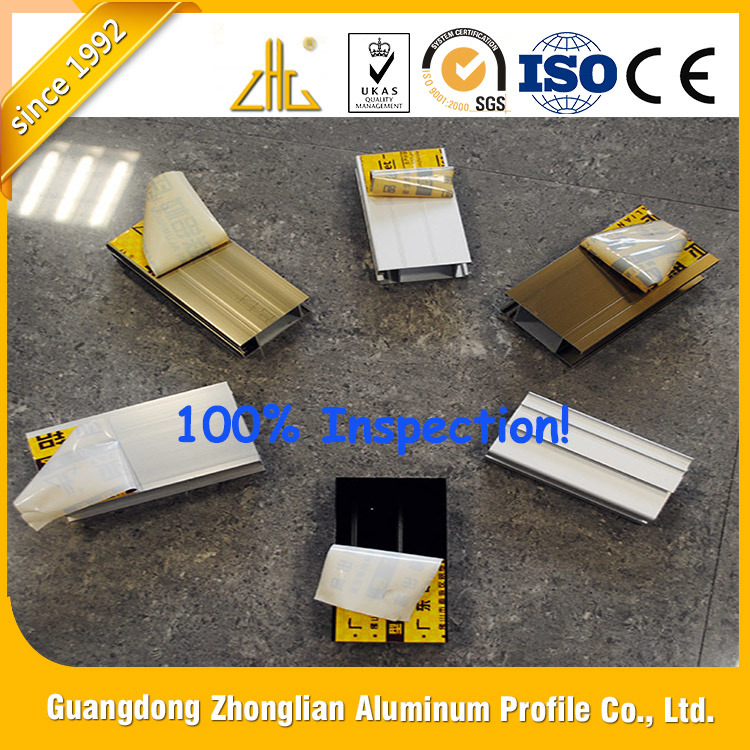

| Item | Aluminum Sliding Door Profile With Crystal Electrophoresis Color |

| Material | Aluminium 6000 series alloy, such as 6061, 6063, 6082, 6463 etc. |

| Temper | T4, T5, T6 |

| Thickness | General profile thickness:0.8-5.0mm; Anodized protection thickness: 8-25um; Powder coating color thickness: 40-120um. |

| Size | 3m-6m per piece, or customized. |

| Shape | Square, flat, round, hollow, oval, triangle, U-profile, L-profile, T-profile, H-profile, customized available. |

| Surface Treatment | Mill-finish, anodized, powder coated, electrophoresis, wood grain, timber, PVDF paint, polishing, brushed. |

| Color | Silver, champagne, black, bronze, gold, white or customized |

| Application | Window and door with thermal break strips, curtain wall, glass wall, furniture, ceiling, kitchen, LED strip, transportation rail, vehicle, motor housing, machine, tent, solar panel, industrial profile, decoration profile etc. |

| Deep Process | CNC, drilling, milling, cutting, tapping, welding, bending, assembling. |

| MOQ | 500 kgs for each item, usually 13-15 tons for a 20GP, 25-28 tons for a 40HQ. |

| OEM service | Drawing, sample or design service offer by customer. |

| Production Capacity | 2400-3000 Metric tons monthly. |

| Brand Name | ZHL (Yalian aluminium) |

| Certificatesand Standard | 1) ISO9001-2008/ISO 9001:2008; 2) CQM CERTIFICATES; 3) SGS, CE, BV, JIS, AS, NZS, QUALICOAT, QUOLANOD AVAILABLE. |

| Guarantee | Surface color can be stable for 10-20 years indoor using. |

| Packing Details | Inside: pack with plastic protective film to protect each piece. |

| Outside: wrap to bundle by waterproof craft paper or EPE film, or customized | |

| Delivery time | Die developing and sample testing: 12-18 days . |

| Mass production: 25-30 days after confirming sample by buyer. | |

| FOB Port | Shenzhen/ Guangzhou/ Foshan |

| Payment Terms | T/T 30% for deposit, balance before delivery. |

| Settlement Terms | Charge by final actual weight or by drawing theoretical weight. |

| Aluminium Alloy Chemical Composition | ||||

| Alloy | 6063 (%) | 6063A (%) | 6061 (%) | 6082 (%) |

| Si | 0.2~0.60 | 0.3~0.60 | 0.4~0.80 | 0.7~1.30 |

| Fe | 0.35 | 0.15~0.35 | 0.7 | 0.5 |

| Cu | 0.1 | 0.1 | 0.15~0.40 | 0.1 |

| Mn | 0.1 | 0.15 | 0.15 | 0.40~1.0 |

| Mg | 0.45~0.90 | 0.60~0.90 | 0.80~1.20 | 0.6~1.20 |

| Cr | 0.1 | 0.05 | 0.04~0.35 | 0.25 |

| Zn | 0.1 | 0.15 | 0.25 | 0.2 |

| Ti | 0.1 | 0.1 | 0.15 | 0.1 |

| Other (each) | 0.05 | 0.05 | 0.05 | 0.5 |

| Other (total) | 0.15 | 0.15 | 0.15 | 0.15 |

| Al | Remainder | Remainder | Remainder | Remainder |

| Characteristics of differerent surface treatment | |

| Mill finish | National standard aluminium billets which is availavle for any kind of surface treatment, with natural burnish. Other products in the market are probably made of recycled aluminium alloy, not available for polishing and other special surface treatment. Moreover, the hardness and planeness cannot meet general standard. |

| Anodizing | Our even anodizing process is used for protecting the surface, and Matt Anodized Silver is the best seller which you can hardly find mechanical lines on the surface (better than other factories) with beautiful fine sand blasting processing. The surface with an anodizing thickness between 10 and 13 μm can hardly be scratched, small scratch marks can be easily removed. However, other profile products with the same color in the market would be easily bruised because of a smaller thickness, and it's also difficult to remove the scratch marks on their surface. |

| Electrophoresis | Electrophoresis surface is more shining and smooth than anodizing, no particles on the surface. |

| Powder coating | Various colors or customized are available. No particles can stay in the air during the process, which makes our profile surface very smooth. Actually this is a technical problem which can hardly be solved by other factories. This is also our product advantage as comparing with other profiles with the same color in the market. |

| Wood grain | Simulated wood grain surface treatment makes a stereoscopic texture look like real wood, it's even superior to real wood. Available for many kinds of wood pattern, hand feeling, film transferring or customization are also available. |

| Polishing | Mirror like finish by buffing and chemical process. |

| Brushed | Shining with line by brushing and chemical process. |

| Establishment | In 1993 |

| Fixed assets | RMB10,000,000 |

| Factory scope | 100,000 m2, and more than 800 employees |

| Annually output | More than 60,000 tons. |

| Mould | We have more than 30000 moulds and a whole set of moulds for window & door of Nigeria |

| Extrusion machine | 21 extrusion line, 600-2500 tons and the biggest one can produce max 350mm width |

| Imported extrusion lines | a) Harni(Japan) anodized & electrophoresis lines b) Electrophoresis lines imported from Korea c) CNC color anodized system d) Wooden grain lines imported from Korea e) Thermal barrier aluminium profile lines imported from Switzerland f) WAGNER (imported from Germany) powder coating & PVDF lines etc. |

| 1. Bundles Packing: |

| -- Inside: packed with plastic protective film to protect each piece |

| -- Outside: Wrap to be bundles by waterproof craft paper or EPE film. |

| 2. Carton Packing: |

| --Inside: Each pcs pack in one plastic bag; |

| --Outside: Numbers of quantity put in one carton. |

| 3. Wood Pallet Packing: |

| -- Inside: Bundles or cartons packing; |

| -- Outside: Numbers of bundles or cartons laden on one wood pallet. |

| 4. Customized packing requirement available. |