Product Specifications

| Prod Model: |

HST PC solid sheet |

| Markets: |

North America,South America,Eastern Europe,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

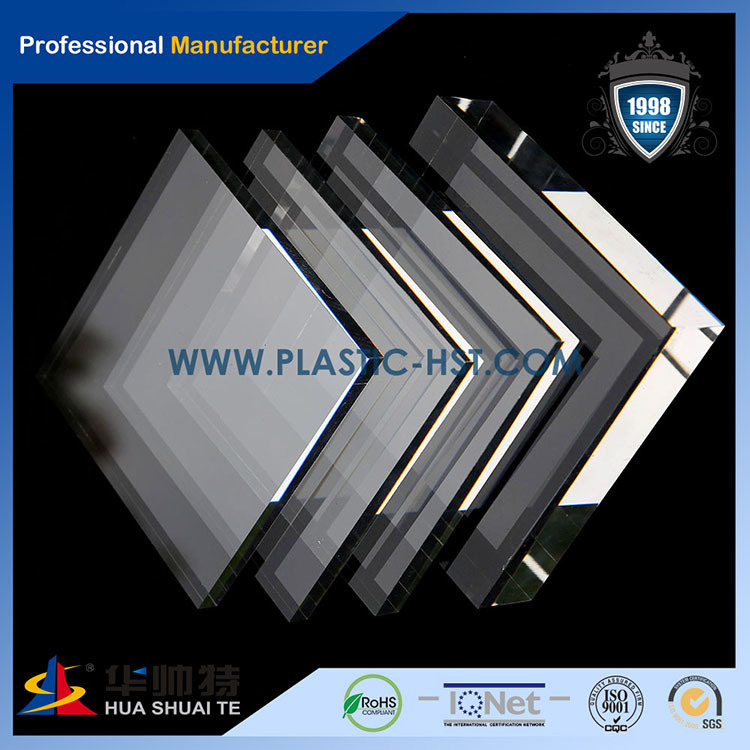

| Thickness: |

1mm-50mm |

| Length: |

Customized |

| Protection: |

The Board Coated with High-Density Ultraviolet ABS |

| Lead Time: |

15 Days |

| Guarantee: |

10 Years |

| Product Material: |

Lexan |

| Certification: |

ISO9001 SGS RoHS |

| Product Color: |

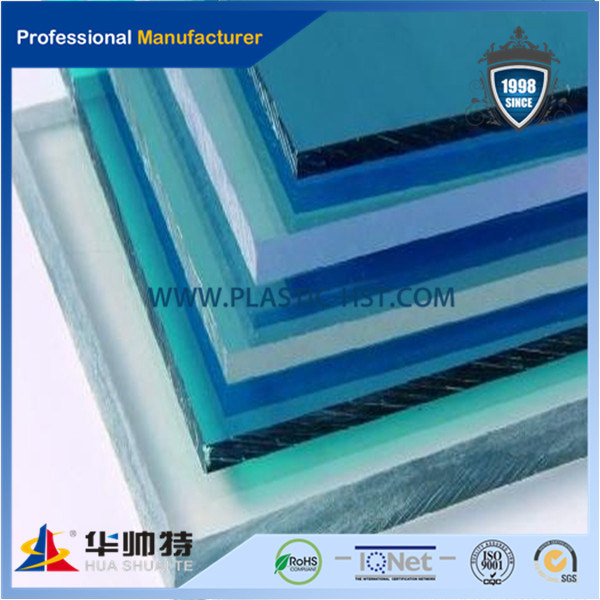

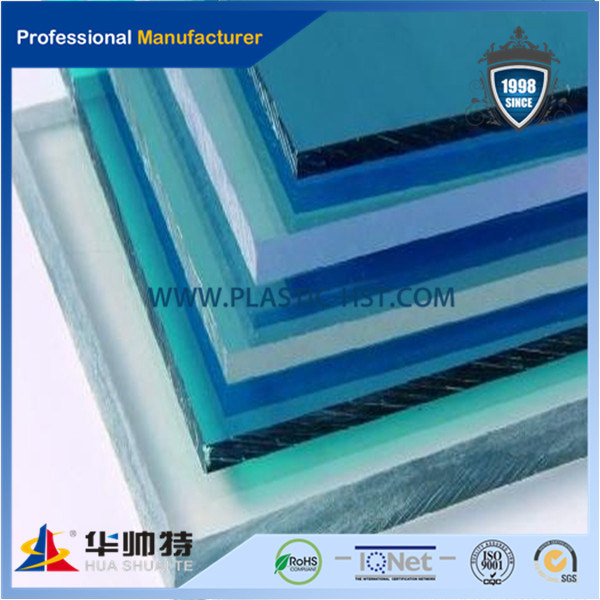

Opal Clear Light Green, Lake Blue Brown |

| Light Transmittance: |

88% |

| Material: |

PC |

Product Description

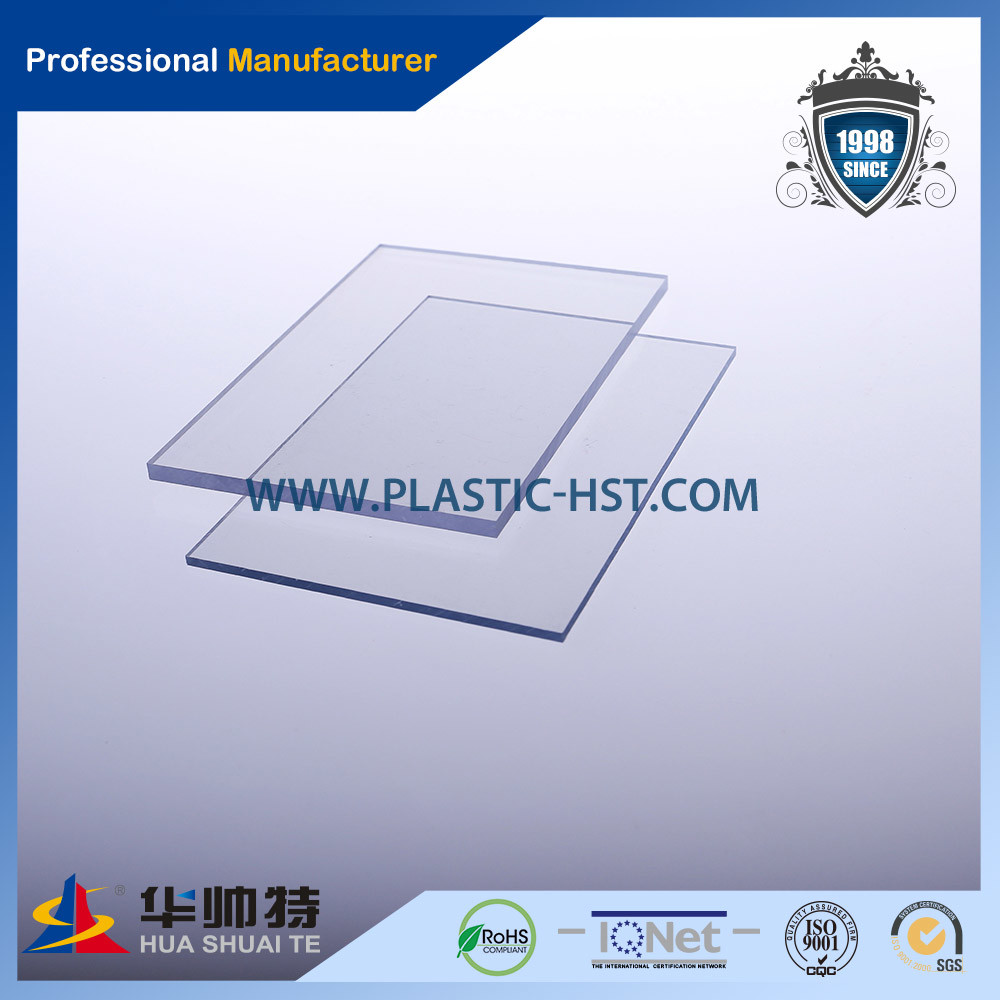

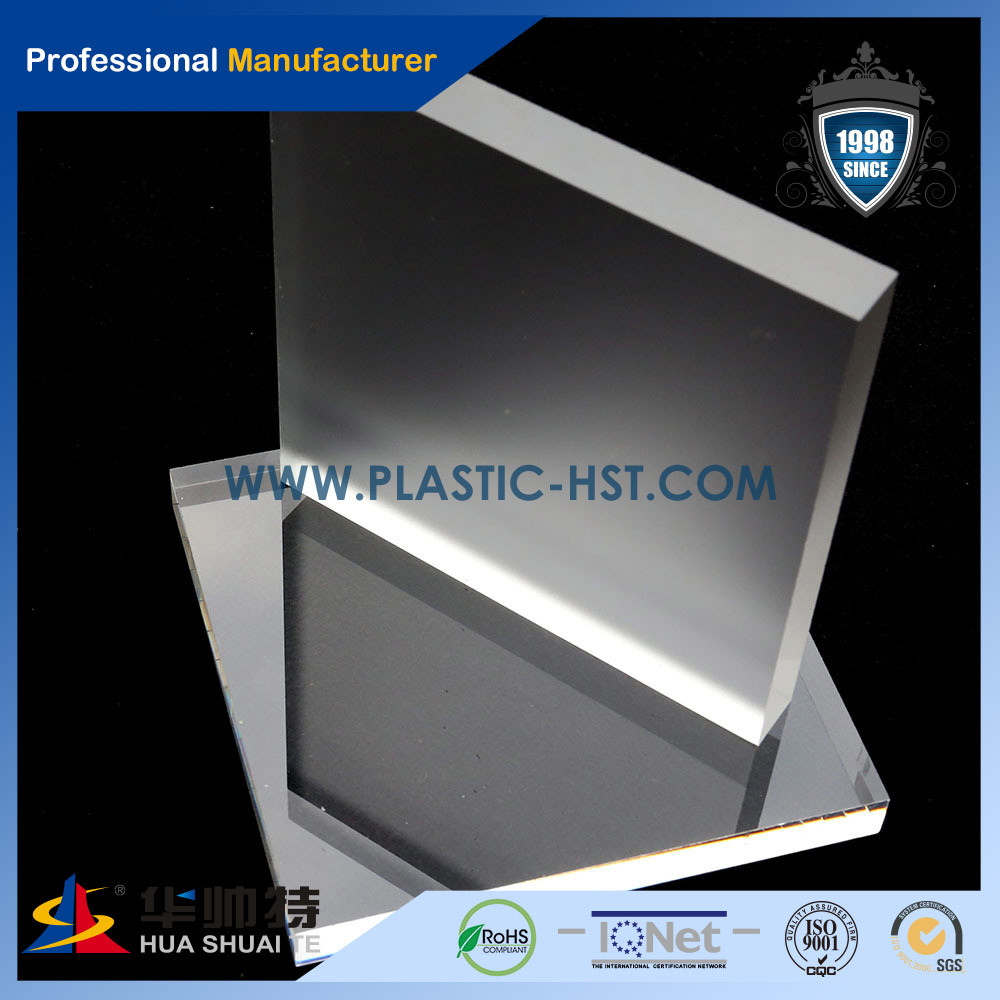

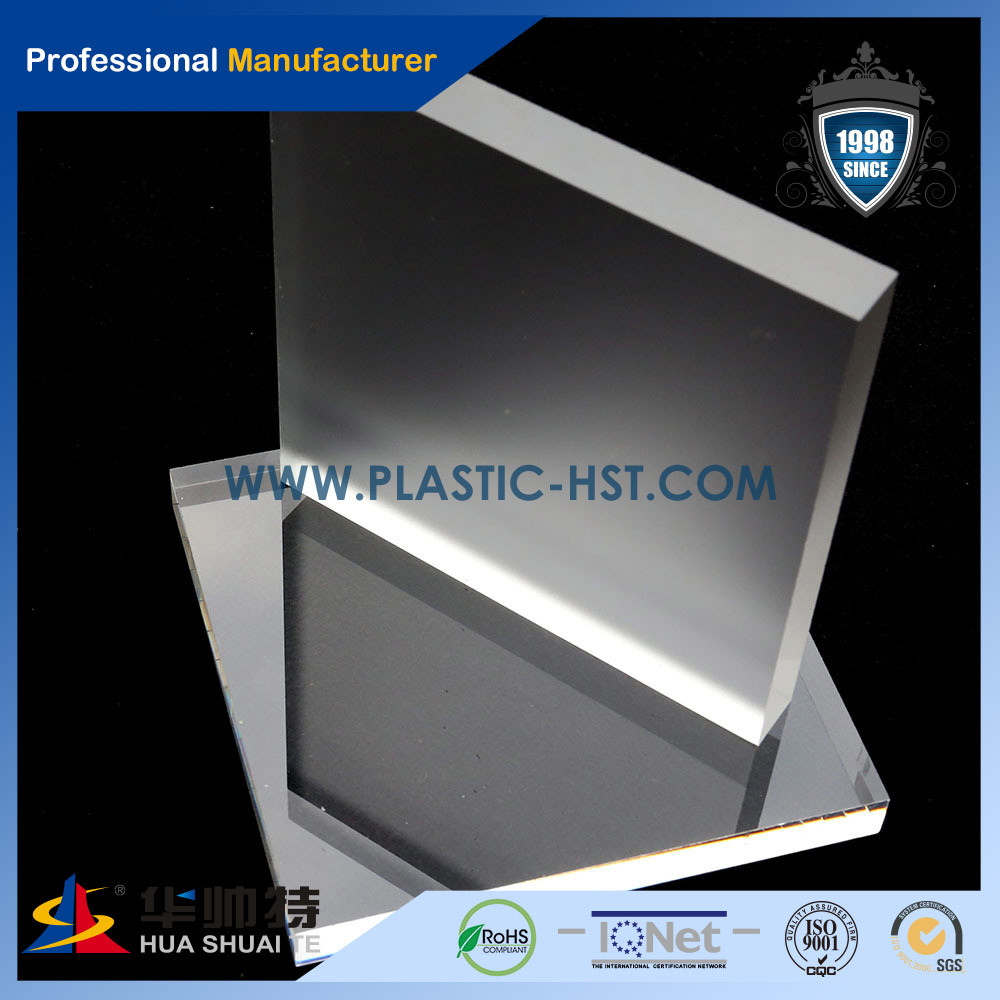

Name:100% Lexan Frosted Polycarbonate Sheet

Product DescriptionPC Resin /PC granules /PC Compound/ PC Powder / PC Particles /PC Virgin Recycled /PC Bead

PC Specifications

1.PC Polycarbonate granule

2.Free sample

3.Injection grade,extrusion grade,blow film grade

4.Widely used in engineering

PC- Polycarbonate

Specific gravity: 1.18-1.20g/cm3

Moulding shrinkage: 0.5-0.8%

Moulding temperature: 230-320C

Drying condition: 8 hours under 110-120C

Usage temperature: -60~120C

PC Usage

1. PC is made into large bulb shade, protective glass, the right and left eyepiece tube of optical instruments. Also, it is used as the transparent materials in plane.

2. PC is good insulation, made into insulated connector, coil frame, tube socket, insulating sleeve, telephone housing and parts, miner's lamp battery shell. Also, it is used to make fine parts of communication equipment, such as CD-ROM, telephone, computer, video recorder, telephone switches, signal relay. The PC film is used for capacitors, insulation foreskin, recorder, color video tape. Etc

3. Machinery and equipment-PC is suitable for gear, rack, worm, bearings, cams, bolts, crank, ratchet, also suitable for machinery and equipment housings, covers and frames.

4. PC can be made into cap, tube, bottle and dental equipment, drug containers and surgical instruments. Even be used as an artificial kidney, artificial lung and other artificial organs.

5. For architectural, PC can be made into Double wall hollow bars, glass of greenhouse. For textile industry, PC is suitable for making bobbin, textile machine bearing. For daily, PC is good material can be made into tableware, toys and models. 1. Specifications:(1). Polycarbonate sheets thickness:

1. Specifications:(1). Polycarbonate sheets thickness:

1). Twin-walls polycarbonate sheet thickness: 4mm, 6mm, 8mm, 10mm, 12mm, etc.

2). Triple-walls polycarbonate sheet thickness: 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, etc.

3). Four-walls polycarbonate sheet thickness: 6mm, 8mm, 10mm, 12mm, 16mm, 20mm, etc.

4). Five-walls polycarbonate sheet thickness: 8mm, 10mm, 12mm, etc.

5). Six-walls polycarbonate sheet thickness: 16mm, 20mm, 25mm, etc.

6). X-Profile polycarbonate sheet thickness: 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, etc.

7). Honeycomb polycarbonate sheet thickness: 6mm, 8mm, 10mm, 12mm, etc.

(2). Polycarbonate sheets width: 2100mm

(3). Polycarbonate sheets length: No limite(Recommend 5800mm, 6000mm, 11800mm, 12000mm to suit 20' container & 40' container)

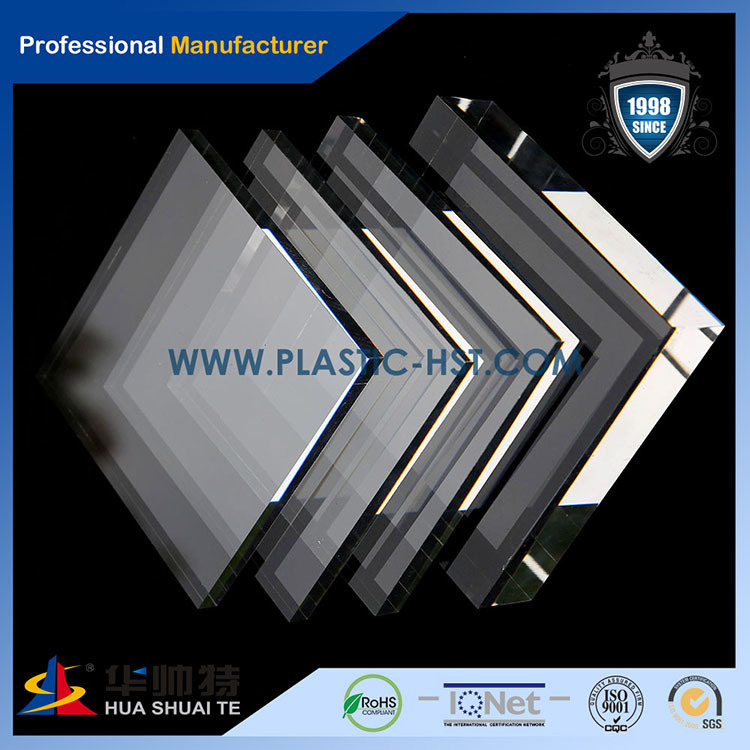

(4). Polycarbonate sheets colour: Clear/transparent, lake blue, green, blue, opal, white, brown/bronze, silvery gray, red, yellow, etc.  PC Serious and Specification

PC Serious and Specification

Test Project | Test Methods | Unit | Typical Values |

| Tensile Stress | GB/T1040-92 | Mpa | ≥50 |

| Flexural Stress | GB/T9341-2000 | Mpa | ≥100 |

| Flexural Modulus | GB/T9341-2000 | Mpa | ≥1500 |

| Notched Impact Strength | GB/T1043-93 | KJ/m2 | ≥20 |

| Elongation At Break | GB/T1040-92 | % | ≥100 |

| Heat Distortion Temperature | GB/T1634-2004 | °C | 110-120 |

| MFR | GB/T3682-2000 | g/10min | 8-18 |

| Oxygen Index (Vertical Burning) | GB/T2408-1996 | 4mm | ≥28 |

| Testing Condition | 23±2°C, 50±5%RH |

Properties | Test method | unit | PC-110 |

| Tensile strength | ASTM D-638 | kg/cm2 | 630 |

| Bending strength | ASTM D-790 | kg/cm2 | 920 |

| IZOD impact strength | ASTM D-256 | kg-cm/cm | 87 |

| Softening point | ASTM D-1525 | °C | 150 |

| MFI | ASTM D-1238 | g/10min | 10.0 |

Why to choose our polycarbonate sheets?1) Quality is reliable, you could check by yourself

Our polycarbonate sheets are 10 years quality guarantee, All of them are made of 100% virgin material, with UV coated, Grade A quality.

2) our price is competitive

We buy a large number of polycarbonate material every time from our material supplier--GE sabc company, they will quote competitive prces to us for our big order, our cost is save, so the prices are competitive.

3) Our good service

Delivery time is 7 days,

Supply free samples to you for developing your market,

Supply suggestion freely

Reply you in 10 hours

4) Our factory with rich experience, 22 years experience.

We know how to produce good quality sheets, and we know the market well. The most important is we know the quality and honest is the life of factory.Contact information:

Name: TonyDepartment: Sales

Mob: 86 18652546893

Established in 1998, Haiyan Huashuaite Plastics Electric Appliance Co., Ltd. is a leading Chinese producer of polycarbonate, PC sheet, PVC foam sheet and PVC profiles. All of our products are manufactured in line with ISO9001, ROTHS and SGS requirements and feature numerous advantages over traditional building materials including age resistance, impact resistance and durability.

Our company employs 250 staff members, including 58 technicians, and has always focused on the application of technology to improve product quality and development. Furthermore, we have 7 imported polycarbonate sheet production lines, 30 PVC profile extrusion lines from Germany and Italy. And 1 cast acrylic sheet line from England.

with quality viewed as the life of our enterprise, we utilize our team of quality inspectors and advanced apparatus to maintain the quality of our products throughout our entire production process. Moreover, our products are currently being used in major projects including Daqing Oil Fields and 2008 Beijing Olympic Games fields and gyms.

Haiyan Huashuaite Plastics Electric Appliances Co., Ltd. Continuously strives to enhance our good reputation whilst perfecting our products, management techniques, processes and level of customer service. If you are interested in any of our products, or are searching for a supplier to fill your OEM order, please contact us to discuss your requirements.